Abstract

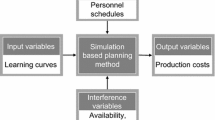

Nowadays the number of product models constantly increases, due to a strong competition to innovate and the reduction of product life cycles, resulting in a more frequent occurrence of production ramp-ups. The production ramp-up combines the product development with the series production and has an impact on the market entry timing. In order to ensure an ideal ramp-up with new developed products being placed on the market as quickly as possible, there has to be an efficient use of existing resources, especially of human resources. Nevertheless, the planning of these resources turns out to be the most important challenge because it is directly related to a great uncertainty. The following article represents an approach that is being developed at the Institute of Production Science (wbk) of the Karlsruhe Institute of Technology (KIT) to optimize the forecast of the personnel requirements during ramp-up by taking into account the dynamic planning variables and organizational basic conditions. Therefore, a method will be developed that provides support to the responsible persons of the respective production ramp-up to calculate the necessary manpower for every single ramp-up phase and to realize the economic optimum. This method focuses on a simulation of the ramp-up process that allows an economically more efficient use of human resources.

Similar content being viewed by others

References

Schuh G, Riedel H, Abels I, Desoi J (2002) Serienanlauf in branchenübergreifenden Netzwerken. Eine komplexe Planungs- und Kontrollaufgabe. wt Werkstattstechnik online 92 Journal 11/12:656–661

Clark KB, Fujiomoto T (1991) Product development performance—strategy, organization, and management in the world auto industry, 1st edn. Harvard Business School Press, Boston, ISBN 0-87584-245-3

Lanza G (2005) Simulationsbasierte Anlaufunterstützung auf Basis der Qualitätsfähigkeiten von Produktionsprozessen. Universität Karlsruhe (TH), Dissertation

Fitzek D (2005) Anlaufmanagement in interorganisationalen Netzwerken. Eine empirische Analyse von Erfolgsdeterminanten in der Automobilindustrie. Universität St. Gallen, Dissertation

Fleischer J, Ender T (2006) Effiziente Produktionsanläufe—Mit ressourcenmanagement in eine erfolgreiche Zukunft. Intelligenter Produzieren Journal 6:17–18

Nakajima Seiichi (1988) Introduction to TPM, 1st edn. Productivity Press, Inc., Cambridge Massachusetts

Sotskov YuriN (1991) The complexity of shop-scheduling problems with two or three jobs. Eur J Oper Res 53:326–336

Lanza G, Ertel A (2011) Ressourceneffizienz im Produktionsanlauf -Personalbedarfsplanung mittels einer kombiniert heuristischen und simulativen Planungsmethode. wt Werkstattstechnik online, Jahrgang 101 (2011), Journal 9

Verein Deutscher Ingenieure (ed) (1996) VDI-Richtlinie 3633, Simulation von Logistik-, Materialfluß- und Produktionssystemen—Begriffsdefinitionen. Entwurf, Beuth, Berlin

Nyhuis P, Heins M, Großhenning P, Fleischer J, Lanza G, Ender T (2005) Simulationsunterstützte Wirkbeziehungsanalyse im Produktionsanlauf. ZWF Zeitschrift für wirtschaftlichen Fabrikbetrieb J 12:746–751

Kuhn A, Reinhart G, Wiendahl H-P (1993) Handbuch Simulationsanwendungen in Produktion und Logistik, 1st edn. Braunschweig, Wiesbaden, Vieweg

Verein Deutscher Ingenieure (ed) (2000) VDI-Richtlinie 3633 page 2, Simulation von Logistik-, Materialfluß- und Produktionssystemen. Entwurf, Beuth, Berlin

Verein Deutscher Ingenieure (ed) (2000) VDI-Richtlinie 3633 page 1, Simulation von Logistik-, Materialfluß- und Produktionssystemen—Grundlagen, Entwurf. Beuth, Berlin

Feldmann K, Reinhart G (2000) Simulationsbasierte Planungssysteme für Organisation und Produktion, 1st edn. Springer Verlag, Berlin. ISBN 3-540-65882-3

Ender T (2009) Prognose von Personalbedarfen im Produktionsanlauf unter Berücksichtigung dynamischer Planungsgrößen. Universität Karlsruhe (TH), Dissertation, pp 60–107

Coordes M, Spieckermann S (2001) Die Ablaufsimulation der virtuellen Prozesskette am Beispiel des neuen Audi A4. Flexibel und kostengünstig. In: 4. Düsseldorfer Produktionstage, Tagung; VDI-Ges. Produktionstechnik (ed) 1597. VDI-Verlag, Düsseldorf, pp 81–96

Tecnomatix (2008) Simulation and optimization with plant simulation. source. http://www.emplant.de:Accessed 03 January 2012

De Jong J (1956) Fertigkeit, Stückzahl und benötigte Zeit. Verband für Arbeitsstudien REFA e.V. (ed) Sonderheft der REFA-Nachrichten, pp 1–15

Wright T (1936) Factors affecting the cost of airplanes. J Aeronaut Sci 3:122–129

Zopounidis C, Pardalos P (2010) Handbook of multicriteria analysis: applied optimization. Springer, Berlin. ISBN 978-3-540-92828-7

Bol G (2003) Induktive statistik, 3rd edn. Oldenbourg Verlag, Oldenbourg. ISBN 3-486-27276-4

Acknowledgments

We extend our sincere thanks to the Deutsche Forschungsgemeinschaft (German Research Foundation) for supporting this research project LA 2351/4-1 “Ressourcenplanung im Produktionsanlauf” (“Resource Planning during Production Ramp-Up”).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lanza, G., Sauer, A. Simulation of personnel requirements during production ramp-up. Prod. Eng. Res. Devel. 6, 395–402 (2012). https://doi.org/10.1007/s11740-012-0394-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-012-0394-6