Abstract

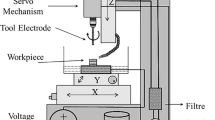

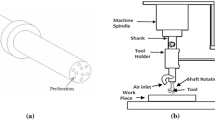

Dry electrical discharge machining (EDM) is an environmentally-friendly alternative of die-sinking EDM process, which it uses gaseous medium instead of liquid as a dielectric. Due to contribution of too many parameters in this process, selection of optimal parameters to increase the process performances is a really crucial concern. In this work, a predictive model based on back-propagation neural network has been applied to correlate the inputs and outputs of dry EDM process. Herein, the inputs were gap voltage, pulse current, pulse on time, duty factor, air intake pressure and rotational speed of tool, and also the main outputs were material removal rate (MRR) and surface roughness (SR). Firstly a back-propagation (BP) and radial basis function neural network have been developed based on data generated from literature [Saha and Choudhary Int J Mach Tools Manuf 49:297–308 (2009)]. Then, the accuracy of proposed models has been checked by their values of error percent via testing data. Hereafter, the most accurate model was served as an objective function to optimize the process using artificial bee colony (ABC) algorithm. In optimization stage, firstly a single objective optimization was fulfilled to determine the optimal factors related to each output separately. Then a multi-objective optimization was implemented to calculate the best solutions in the case of higher MRR and lower SR simultaneously. Results indicated that the predictive model can estimate the dry EDM process precisely, and also the ABC algorithm could find the optimal solution sets logically.

Similar content being viewed by others

Abbreviations

- Vg (V):

-

Gap voltage

- Id (A):

-

Discharge current

- Ton (μs):

-

Pulse on time

- D (%):

-

Duty factor

- N (rpm):

-

Tool rotational speed

- P (kPa):

-

Air intake pressure

- MRR (mm3):

-

Material removal rate

- SR (μm):

-

Surface roughness

References

Ramani V, Cassidenti ML (1985) Inert-gas electrical discharge machining. NASA Technical Brief Number NPO 15660

Kunieda M, Furuoya S, Taniguchi N (1991) Improvement of EDM efficiency by supplying oxygen gas into gap. CIRP Ann Manuf Technol 40:215–218

Kunieda M, Yoshida M, Taniguchi N (1997) Electrical discharge machining in gas. CIRP Ann Manuf Technol 46:143–146

Saha SK, Choudhury SK (2009) Experimental investigation and empirical modeling of the dry electric discharge machining process. Int J Mach Tools Manuf 49(3–4):297–308

Govindan P, Joshi SS (2010) Experimental characterization of material removal in dry electrical discharge drilling. Int J Mach Tools Manuf 50:431–443

Kuneida M, Miyoshi Y, Takaya T, Nakajima N, Bo YZ, Yoshida M (2003) High speed 3D milling by dry EDM. CIRP Ann Manuf Technol 52:147–150

Yu Z, Jun T, Masanori K (2004) Dry electrical discharge machining of cemented carbide. In: 14th international symposium on electromachining (ISEM XIV), J Mater Process Technol 149 (1–3):353–357

Zhanbo Y, Takahashi J, Nakajima N, Sano S, Karato K, Kuneida M (2005) Feasibility of 3-D surface machining by dry EDM. Int J Electr Mach 10:15–20

Soni JS, Chakraverti G (1994) Machining characteristics of titanium alloy with rotary electro-discharge machining. Wear 171:51–58

Chattophaday KD, Veram S, Satsangi PS, Sharma PC (2009) Development of empirical model for different process parameters during rotary electrical discharge machining of copper-steel (EN-8) system. J Mater Process Technol 209:1454–1465

Mohan B, Rajadurai A, Satyanarayana KG (2002) Effect of SiC and rotation of tool electrode on electric discharge machining of Al–SiC composite. J Mater Process Technol 124:297–304

Kuppan P, Rajadurai A, Narayanan S (2008) Influence of EDM process parameters in deep hole drilling of Inconel 718. Int J Adv Manuf Technol 38:74–84

Sohani MS, Gaitonde VN, Siddeswarappa B, Deshpande AS (2009) Investigations into the effect of tool shapes with size factor consideration in sink electrical discharge machining (EDM) process. Int J Adv Manuf Tech 45:1131–1145

Tsai KM, Wang PJ (2001) Comparisons of neural network models on material removal rate in electrical discharge machining. J Mater Process Technol 117:111–124

Kumar S, Chodhury SK (2007) Prediction of wear and surface roughness in electro-discharge diamond grinding. J Mater Process Technol 191:206–209

Mandal D, Pal SK, Saha P (2007) Modeling of electrical discharge machining process using back propagation neural network and multi-objective optimization using non-dominating sorting genetic algorithm-II. J Mater Process Technol 186:154–162

Yang SH, Srinivas J, Mohan S, Lee DM, Blajee S (2009) Optimization of electric discharge machining using simulated annealing. J Mater Process Technol 209:4471–4475

Akay B, Karaboga D Artificial bee colony algorithm for large-scale problems and engineering design optimization. J Intell Manuf. doi:10.1007/s10845-010-0393-4

Basturk B, Karaboga D (2006) An artificial bee colony (ABC) algorithm for numeric function optimization. In: Proceedings of the IEEE swarm intelligence symposium, Indianapolis, IN, USA, May 12–14

Rao RV, Pawar PJ (2009) Modelling and optimization of process parameters of wire electrical discharge machining. Proc IMechE, Part B J Eng Manuf 223(11):1431–1440

Samanta S, Chakraborty S (2011) Parametric optimization of some non-traditional machining processes using artificial bee colony algorithm. Eng Appl Artif Intell 24:946–957

Chen HC, Lin JC, Yang YK, Tsai CH (2010) Optimization of wire electrical discharge machining for pure tungsten using a neural network integrated simulated annealing approach. Expert Syst Appl 37:7147–7153

Joshi SN, Pande SS (2011) Intelligent process modeling and optimization of die-sinking electric discharge machining. Appl Soft Comput 11:2743–2755

Singh PN, Raghukandan N, Pai BC (2004) Optimization by Grey relational analysis of EDM parameters on machining Al–10 % SiCP composites. J Mater Process Technol 155–156:1658–1661

Hagan MT, Demuth HB, Beale M (1996) Neural network design. PWS Publishing Company, Boston, MA

Rao SS (2009) Engineering optimization: theory and practice. Wiley, Hoboken, NJ

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Teimouri, R., Baseri, H. Improvement of dry EDM process characteristics using artificial soft computing methodologies. Prod. Eng. Res. Devel. 6, 493–504 (2012). https://doi.org/10.1007/s11740-012-0398-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-012-0398-2