Abstract

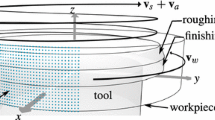

We present recent developments in modelling and simulation of internal traverse grinding, a high speed machining process which enables both a large material removal rate and high surface quality. We invoke a hybrid modelling framework, including a process scale model, simulations on a mesoscale capturing the proximity of a single cBN grain and an analysis framework to investigate the grinding wheel topography. Moreover, we perform experiments to verify our simulations. Focus in this context is the influence of the cutting speed variation on the grain specific heat generation.

Similar content being viewed by others

References

Marschalkowski K (2010) Beitrag zur Prozessentwicklung für das Hochleistungsinnenrund-Schälschleifen mit galvanisch gebundenen CBN-Schleifscheiben. Dissertation, TU Dortmund

Klocke F, Brinksmeier E, Weinert K (2005) Capability profile of hard cutting and grinding processes. CIRP Ann Manuf Technol 54:22–45

Holtermann R, Schumann S, Menzel A, Biermann D (2012) Ansätze zur modellierung und simulation des Innenrundschälschleifens. Diam Bus 40:30–41

Treffert C (1994) Hochgeschwindigkeitsschleifen mit galvanisch gebundenen CBN-Schleifscheiben. Dissertation, RWTH Aachen

Tawakoli T, Schmid R, Vesali A, Padilla-Ley A (2011) Rekonstruktion der Schleifscheibentopographie mit Hilfe der Bildverarbeitungsmethoden. dihw Diamant Hochleistungswerkzeuge 4:32–39

Warnecke G, Zitt U (1998) Kinematic simulation for analyzing and predicting high-performance grinding processes. CIRP Ann Manuf Technol 1:265–270

Aurich JC, Kirsch B (2012) Kinematic simulation of high-performance grinding for analysis of chip parameters of single grains. CIRP J Manuf Sci Technol 5:164–174

Hecker R, Liang SY (2003) Predictive modeling of surface roughness in grinding. Int J Mach Tools Manuf 43:755–761

Stepień P (2009) A probabilistic model of the grinding process. Appl Math Model 33:3863–3884

Klocke F (2009) Manufacturing processes 2—grinding, honing, lapping. Springer, Berlin

Denkena B, Tönshoff HK (2011) Spanen—Grundlagen, 3rd edn. Springer, Berlin

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In: Proceedings of the 7th international symposium on Ballistics. The Hague, The Netherlands, pp 541–547

Huang Y, Liang S (2003) Force modelling in shallow cuts with large negative rake angle and large nose radius tools. Int J Adv Manuf Technol 22:626–632

Hortig C (2011) Local and non-local thermomechanical modeling and finite-element simulation of high-speed cutting. Dissertation, TU Dortmund

Hortig C, Svendsen B (2007) Simulation of chip formation during high-speed cutting. J Mater Process Technol 186:66–76

Zienkiewicz OC, Zhu JZ (1992) The superconvergent patch recovery and a posteriori error estimates. Part 1: the recovery technique. Int J Num Methods Eng 33:1331–1364

Poulachon G, Moisan A (2001) A study of chip formation mechanisms in high speed cutting of hardened steel. In: Schulz H (ed) Scientific fundamentals of HSC. Hanser, Munich, pp 11–21

Acknowledgments

Financial support by the Deutsche Forschungsgemeinschaft (DFG) in the context of SPP 1480 (project IDs: ME 1745/7–2; BI 498/23-1) is gratefully acknowledged.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Holtermann, R., Schumann, S., Menzel, A. et al. Modelling, simulation and experimental investigation of chip formation in internal traverse grinding. Prod. Eng. Res. Devel. 7, 251–263 (2013). https://doi.org/10.1007/s11740-013-0449-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-013-0449-3