Abstract

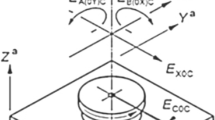

The following article presents an approach for a novel positioning stage as basic component of a small machine tool. It is a parallelkinematic machine (BiGlide mechanism), which converts the linear motion of two linear axes into a planar motion. The novel features, which were identified to be crucial for the transition from conventional machine tools to small ones, are: compact and precise feed axes, backlash free motion transmission, and direct measurement of the tool-center-point position and the ability of additional fine positioning. The proposed implementations are: hydraulic feed units, dry slide bearings as rotational joints, highly precise radar sensors and active variable-length struts of the parallelkinematic machine. Some of the simulation results are presented along with measurements of a currently designed prototype.

Similar content being viewed by others

References

Wulfsberg JP, Grimske S, Kohrs P, Kong N (2010) Kleine Werkzeugmaschinen für kleine Werkstücke - Zielstellungen und Vorgehensweise des DFG-Schwerpunktprogramms 1476. wt Werkstattechnik online, Jahrgang 100, vol 11/12, pp 886–891

Schubert A, Neugebauer R, Schulz B (2007) System concept and innovative component design for ultraprecision for assembly processes. Towards Synth Micro-Nano Syst Part 2

Klar R, Brecher C, Wenzel C (2008) Development of a dynamic high precision compact milling machine. In: Proceedings of euspen international conference, Zurich/CH

Wulfsberg JP, Redlich T, Kohrs P (2010) Square foot manufacturing: a new production concept for micro manufacturing. Prod Eng 4(1):75–83

Tanaka M (2001) Development of desktop machining microfactory. Riken Rev Nr. 34, S. 46–49 Journal Code J0877A.I, Internet: http://sciencelinks.jp/j-east/article/200115/000020011501A0520776.php. (14.1.2013)

Kussul E, Baidyk T, Ruiz-Huerta L, Caballero-Ruiz A, Velasco G, Kasatkina L (2002) Development of micromachine tool prototypes for microfactories. J Micromech Microeng 12:795–812

Fleischer J, Seemann W, Zwick T, Ayhan S, Bauer J, Kern D, Scherr D (2012) Antriebsmodul für die Mikrobearbeitung - Parallelkinematisches hydraulisches An-triebsmodul mit Radarpositionsmessung. wt Werkstattstechnik online, Jahrgang 102, vol 11/12, Verlag Springer-VDI-Verlag GmbH & Co. KG, Düsseldorf, pp 724–729

Lanza G, Fleischer J, Kotschenreuther J, Peters J, Schlipf M (2007) Statistical modelling of process parameters in micro cutting. J Eng Manuf B 222(1):15–22

Stan SD, Maties V, Balan R (2007) Optimal design of a 2DoF micro parallel robot using genetic algorithms.In: IEEE international conference on integration technology, pp 719–724

Astashev VK, Babitsky VI (2007) Ultrasonic processes and machines: dynamics, control and applications. Springer, Berlin Heidelberg. ISBN 978-3-540-72060-7

Armstrong-Helouvry B (1991) Control of machines with friction. Kluwer Academic Publishers, Dordrecht. ISBN 0-7923-9133-0

Fleischer J, Bauer J (2012) Highly integrated piezo-hydraulic feed axis. 5th CIRP Conference on high performance cutting, 4.6.2012-6.6.2012, Zurich, Switzerland, Procedia CIRP 1, pp 342–346

Ayhan S, Pahl P, Kayser Th, Pauli M, Zwick T (2011) Frequency estimation algorithm for an extended FMCW radar system with additional phase evaluation. In:Proceedings of the German microwave conference GeMiC, Darmstadt, Germany

Ayhan S, Pauli M, Kayser T, Scherr S, and Zwick T (2011) FMCW radar system with additional phase evaluation for high accuracy range detection. In: Proceedings of the European radar conference—EuRAD, Manchester, England, pp 117–120

Ayhan S, Vu-Duy V, Pahl P, Scherr S, Hübner M, Becker J, Zwick T (2012) FPGA controlled DDS based frequency sweep generation of high linearity for FMCW radar systems. In: Proceedings of the German microwave conference GeMiC, Ilmenau, Germany

Pauli M, Ayhan S, Scherr S, Rusch C, Zwick T (2012) Range detection with micrometer precision using a high accuracy FMCW radar system invited paper, in 9th international multi-conference on systems, signals and devices (SSD), Chemnitz, Germany

Scherr S, Ayhan S, Pauli M, Zwick T (2012) Accuracy limits of a K-band FMCW radar with phase evaluation. In: Proceedings of the European radar conference—EuRAD, Amsterdam, Netherlands

Pohl N, Jaschke T, Scherr S, Ayhan S, Pauli M, Zwick T, Musch T (2013) Radar measurements with micrometer accuracy and nanometer stability using an ultra-wideband 80 GHz radar system. In: IEEE topical meeting on wireless sensors and sensor networks (WiSNet) Austin, Texas

Acknowledgments

This paper is based on investigations of the collaborative research program SPP1476, which is kindly supported by the German Research Foundation (DFG).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bauer, J., Kern, D., Ayhan, S. et al. Planar positioning stage for micro machining. Prod. Eng. Res. Devel. 7, 511–516 (2013). https://doi.org/10.1007/s11740-013-0474-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-013-0474-2