Abstract

Today most technical parts and components are made of monolithic materials. Nevertheless, the previously used monolithic materials reach their technological and constructive limits, so that an improvement of the component properties can be realized by hybrid parts. Forging of previously joined semi-finished products to net shape hybrid components is a promising method to produce functional adapted parts in a few process steps. This new process chain offers a number of advantages compared to other manufacturing technologies. Examples are the production of specific load-adapted forging parts with a high level of material utilization, an improvement of the joining zone caused by the followed forming process and an easy to implement joining process because of the simple geometries of the semi-finished products. This paper describes the production process of hybrid steel parts, which are produced by a combination of a deposition welding process with a subsequent hot forging (upsetting) or cross-wedge-rolling. It could be shown that the innovative process chain enables the production of hybrid parts whereby the forging processes lead to an improvement of the mechanical properties of the laser deposited material.

Similar content being viewed by others

References

Landerl C et al. Das neue BMW aluminium-magnesium-Verbundkurbelgehäuse. In: Verein Deutscher Ingenieure e. V.: VDI-Berichte, no 1830, VDI-Verlag Düsseldorf 2004, pp 69–91

Kerber K (2011) Verfahren zum Verbundguss der Leichtmetalle Aluminim und Magnesium durch den Druckguss. Dissertation, Berichte aus dem Institut für Werkstoffkunde, Leibniz Universität Hannover, PZH Verlag

Domblesky J, Kraft F, Druecke B, Sims B (2006) Welded preforms for forging. J Mater Process Technol 171:141–149

Lehmann T, Stockmann M, Kittner K, Binotsch C, Awiszus B (2011) Bruchmechanische Eigenschaften von Al/Mg-Verbunden und deren Fließverhalten im Herstellungsprozess. Materialwiss Werkstofftech 7(42):612–623

LEIBER Group: Hybridschmiedetechnik ermöglicht 1,1 kg leichteren Antriebsflansch. In: lightweightdesign.http://www.lightweightdesign.de/index.php;do=show/alloc=135/id=15663/site=lwd/sid=12779379724fa0e317e1310562186293, 02.04.2012

Küper A (2011) Zahnflankentragfähigkeit verbundgeschmiedeter Zahnräder, Dissertation, IFUM, Leibniz Universität Hannover, PZH Verlag, ISBN 3-936888-79-5

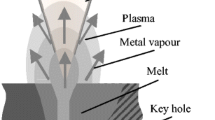

Hermsdorf J, Ostendorf A, Stahlhut C, Barroi A, Otte F, Kling R (2008) Guidance and stabilisation of electric arc welding using Nd: YAG laser radiation, PICALO 2008 paper (707), pp 335–340

Stute U, Kling R, Hermsdorf J (2007) Interaction between electrical arc and Nd: YAG laser radiation. Ann CIRP 56/1/2007:197–200

Hermsdorf J, Otte F, Kling R (2009) Development of the LGS-GMA welding process. Lasers Manuf 155–160

Barroi A, Hermsdorf J, Kling R (2010) Development of a laser-stabilized gas metal arc cladding process for hard steel deposition material. In: Proceedings of LPM, pp 3–7

Barroi A, Hermsdorf J, Kling R (2011) Cladding and additive layer manufacturing with a laser supported arc process: solid freeform symposium, 2011, pp 164–174

Behrens B-A (2006) Handbuch Umformtechnik, Grundlagen, Technologien, Maschinen. Springer, Berlin, pp 488–489

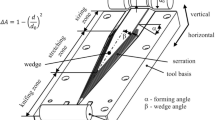

Klocke F (2006) Fertigungsverfahren 4, Umformen. Springer, Berlin, pp 32–37

Li Q, Lovell M (2008) Cross wedge rolling failure mechanisms and industrial application. Int J Adv Manuf Technol 37(3–4):265–278

Pater Z (2003) Tools optimization in cross wedge rolling. J Mater Process Technol 139(1–3):153–159

Meyer M, Stonis M, Behrens B-A (2012) Cross wedge rolling of preforms for crankshafts. In: Key engineering materials, vol 504–506. Trans Tech Publications Ltd., pp 205–210

Kache H, Stonis M, Behrens B-A (2012) Development of a warm cross wedge rolling process using FEA and downsized experimental trials. In: Production engineering, research and development, vol 6, no 4–5. Springer, Berlin, pp 339–348

Li Q et al (2002) Investigation of the morphology of internal defects in cross wedge rolling. J Mater Process Technol 125–126:248–257

Neugebauer R, Lorenz B, Steger J (2009) Cross wedge rolling to preform light metal forgings. In: cbm—metal metters, p 13

Johnson W, Mamalis AG (1977) A survey of some physical defects arising in metal working processes. In: 17th international MTDR conference. IFC Ltd., London, pp 607–621

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Behrens, BA., Overmeyer, L., Barroi, A. et al. Basic study on the process combination of deposition welding and subsequent hot bulk forming. Prod. Eng. Res. Devel. 7, 585–591 (2013). https://doi.org/10.1007/s11740-013-0478-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-013-0478-y