Abstract

A process for the production of steel strips with an optimized cross section by means of twin-roll strip casting has recently been developed at the Institute of Metal Forming and offers considerable technical and commercial potentials. This production concept is based on the use of profiled casting rolls which continuously transfer the profile geometry to the solidified strip. In order to reduce the internal porosity and improve the surface finish the cast strip was hot rolled using profiled rolls. Offline and inline rolling experiments were performed to prove the effectiveness of this combined forming process. This paper describes the design of a proper rolling tool and the effect of this forming step on the final profile geometry, surface quality, internal porosity and mechanical properties of the strip. The experiments showed that a rolling step with 15 % thickness reduction already allows the global internal porosity to be reduced by 48 % and the strip surface roughness to reach a minimum value of Ra = 2.3 µm. The tensile strength is improved after the hot rolling operation and the obtained values are within the 500–700 MPa range specified by the norm EN 10088-3 for the stainless steel AISI 304. The prescribed ultimate elongation of 45 % is also reached.

Similar content being viewed by others

References

Pallett RJ, Lark RJ (2001) The use of tailored blanks in the manufacture of construction components. J Mater Process Technol 117:249–254

Schuberth S, Schael I, Vogt H (2008) Tailored strips: a cost and weight saving prospect for automotive exhaust systems. In: Karjalainen P (ed) Proceedings: Helsinki, Finland, June 10–13, 2008. Jernkontoret, Stockholm, pp 661–667

Hirt G, Dávalos-Julca DH (2012) Tailored profiles made of tailor rolled strips by roll forming—Part 1 of 2. Steel Res Int 83:100–105

Sheng Z (2008) Formability of tailor-welded strips and progressive forming test. J Mater Process Technol 205:81–88

Kopp R, Böhlke P, Hohmeier P, Wiedner C (2002) Metal forming of lightweight structures. In: Proceedings of the 5th International ESAFORM Conference on Material Forming 2002, pp 13–18

Thyssen Krupp Steel, Tailored Strips: Data sheet, http://incar.thyssenkrupp.com/7_03_021_Tailored_Strips.html. Last Accessed 21 May 2014

Spoettl M, Mohrbracher H (2009) A review of laser welding technology for mass production of tailored blanks. ISAS 2009:382–389

Merklein M, Johannes M, Lechner M, Kuppert A (2014) A review on tailored blanks-production, applications and evaluation. J Mater Process Technol 214:151–164

Schueren M, Campbell P, Blejde W, Mahapatra R (2007) The CASTRIP process: an update on process development at nucor steel’s first commercial strip casting facility. In: AISTech 2007 Conference Proceedings, Indianapolis, US

SCANMET IV (2012). In: Proceedings of the 4th international conference on process development in iron and steelmaking; 10–13 June 2012, Luleå, Sweden, Swerea/MEFOS

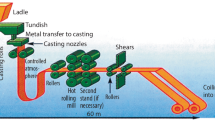

Zapuskalov N (2003) Comparison of continuos strip casting with conventional technology. ISIJ Int 43:1115–1127

Daamen M, Wietbrock B, Richter S, Hirt G (2011) Strip casting of a high manganese steel (FeMn22CO.6) compared with a process chain consisting of ingot casting and hot forming. Steel Res 82:70–74

Daamen M, Förster T, Hirt G (2011) Experimental and numerical investigation of double roller casting of strip with profiled cross section. Steel Res Int Spec Ed 10th ICTP 2011: 93–97

Acknowledgments

The authors gratefully acknowledge the financial support of the Deutsche Forschungsgemeinschaft (DFG) within the project “Dünnbandgießen von profilierten Flachprodukten—Profilgießen”. The authors also would like to express their thanks to ThyssenKrupp Steel Europe AG for the productive cooperation and express their gratitude to the mechanical staff A. Galle and A. Karul.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vidoni, M., Daamen, M., Gastreich, J. et al. Hot rolling of AISI 304 tailored strips produced by twin roll strip casting. Prod. Eng. Res. Devel. 8, 619–626 (2014). https://doi.org/10.1007/s11740-014-0567-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-014-0567-6