Abstract

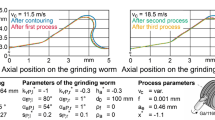

Due to its high productivity, continuous generating grinding is a popular finishing process for gears with small and middle sized modulus. However, concerning the complex temporally and locally changing contact conditions and their influence on the ground gear only restricted knowledge is available. In this study, theoretical investigations are conducted to identify the influence of tool and workpiece setting on the resulting cutting speed in the contact zone for continuous generating grinding especially with a higher number of starts. Depending on the geometrical setting of the gear and grinding worm, the resulting cutting speed can be higher or lower than the set tool circumferential speed. A comparable consideration for the dressing process and the resulting dressing speed ratio can be made.

Similar content being viewed by others

References

Denkena B, Köhler J, Woiwode S (2012) Leistungsfähige Werkzeugkonzepte für das kontinuierliche Wälzschleifen. wt Werkstattstechnik online 102/6:377:382

Klocke F, Gorgels C, Vasiliou V (2009) Analysis of the influence of gear dimensions on cutting speed and contact conditions during the gear honing process. Prod Eng Res Dev 3:255–259

Karpuschewski B, Knoche H-J, Hipke M (2008) Gear finishing by abrasive processes. CIRP Ann Manuf Technol 57:621–640

Reichstein M, Catoni F (2006) Grinding of gears with vitreous bonded CBN-worms. Ann CIRP 55:355–358

Karpuschewski B, Knoche HJ, Hipke M (2008) Gear finishing by abrasive processes. CIRP Ann Manuf Technol 57:621–640

Denkena B, Tönshoff HK (2011) Spanen – Grundlagen. Springer Verlag Heidelberg, Dordrecht, London, New York, 3. Auflage

Klocke F, König W (2005) Fertigungsverfahren 2 – Schleifen, Honen, Läppen. Springer Verlag, Berlin, Heidelberg, New York, 4. Auflage

Köllner T (2000) Verzahnungshonen - Verfahrenscharakteristik und Prozessanalyse. Dr.-Ing. Dissertation, RWTH Aachen

Rütti R (2000) Beitrag zur Prozessmodellierung am Beispiel des Verzahnungshones. Dr.-Ing. Dissertation, ETH Zürich

Denkena B, Köhler J, Woiwode S (2014) Dressing of vitrified bonded CBN tools for continuous generating grinding. Prod Eng. doi:10.1007/s11740-014-0541-3

Köhler J, Schindler A, Woiwode S (2012) Continuous generating grinding—tooth root machining and use of CBN-tools. CIRP Ann 61:291–294

Stimpel F (2009) Technologische Kenngrößen für das kontinuierliche Wälzschleifen von Evolventenverzahnungen. Dr.-Ing. Dissertation, Universität Hannover

Muhs D, Wittel H, Jannasch D, Voßdiek J (2007) Roloff/Matek Maschinenelemente. Vieweg Verlag, Wiesbaden, 18. Auflage

Norm DIN3960 (1987) Begriffe und Bestimmungsgrößen für Stirnräder (Zylinderräder) und Stirnradpaare (Zylinderpaare) mit Evolventenverzahnung. Deutsches Institut für Normung Beuth Verlag, Berlin

Norm DIN8000 (1962) Bestimmungsgrößen und Fehler an Wälzfräsern für Stirnräder mit Evolventenverzahnung – Grundbegriffe. Deutsches Institut für Normung Beuth Verlag, Berlin

Denkena B, Reichstein M, Catoni F (2005) Kontinuierliches Wälzschleifen von Verzahnungen mit abrichtbaren CBN-Werkzeugen. Optimierung der Einsatzvorbereitung keramisch gebundener CBN-Wälzschnecken. wt-online 6:453–458

Türich A (2002) Werkzeugprofilerzeugung für das Verzahnungsschleifen. Dr.-Ing. Dissertation, Universität Hannover

Acknowledgments

The presented investigations were undertaken with support of the German Research Foundation within the project “Strategien zur Erhöhung der Leistungsfähigkeit von Zahnrädern durch kontinuierliches Wälzschleifen” (DE447/103-1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Denkena, B., Köhler, J., Schindler, A. et al. Kinematic analysis of the cutting speed for continuous generating grinding. Prod. Eng. Res. Devel. 9, 35–40 (2015). https://doi.org/10.1007/s11740-014-0578-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-014-0578-3