Abstract

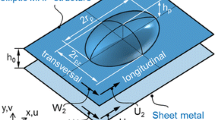

Recently, the velocity distribution within an elliptical machine hammer peened (MHP) surface structure was discussed by solving analytically the Reynolds equation using Full-Sommerfeld boundary condition (Trauth et al. in Tribol Lett 60(19):1–13, 2015). However, in order to design the MHP process to obtain defined friction characteristics and load capacities of a fluid film, the pressure distribution has to be analyzed as well. Thus, in this contribution, the fluid pressure is discussed using Full-Sommerfeld first, then the previous work is extended by the Swift–Stieber boundary condition to account for cavitation effects. Thereby, the influence of geometry and process parameters on the fluid pressure, load capacity and coefficient of friction will be analyzed both using an approach based on absolute and dimensionless numbers. To asses the influence of lateral effects, the semi-analytic 1D results are compared to numerical 2D results based on the Raimondi approach. Thereby, a recommendation for a surface design manufactured by machine hammer peening is formulated.

Similar content being viewed by others

Abbreviations

- a :

-

Longer semi-axis of the ellipse (mm)

- b :

-

Shorter semi-axis of the ellipse (mm

- \( C_1, C_2 \) :

-

Constant of integration (–)

- d :

-

Diameter of the MHP head (mm

- f :

-

Frequency of the MHP head (Hz

- F :

-

Impact force of the MHP head (N)

- \( F_L \) :

-

Load bearing capacity (N)

- \( \tilde{F_L} \) :

-

Dimensionless load capacity (–)

- \( F_T \) :

-

Shear force (N)

- h, h(x):

-

Height of the dimple (mm)

- \( h_0 \) :

-

Fluid film thickness (mm)

- \( h_p \) :

-

Maximum structure depth (mm)

- \( \tilde{h} \) :

-

Dimensionless structure depth (–)

- l :

-

Length of the computational domain (mm)

- \( l_p \) :

-

Line pitch (mm)

- p, p(x):

-

Fluid pressure (MPa mm)

- \( p_1, p_2 \) :

-

Inlet (1) and outlet fluid pressure (MPa mm)

- \(\tilde{p} \) :

-

Dimensionless fluid pressure (–)

- \( r_p \) :

-

Structure length (mm)

- s :

-

Substitution variable (–)

- t :

-

Substitution variable (–)

- \( U_1, U_2\) :

-

Longitudinal velocity of contact body 1 or 2 (mm/s)

- v :

-

Machine feed (mm/s)

- \( W_1, W_2 \) :

-

Longitudinal velocity of contact body 1 or 2 (mm/s)

- \( x* \) :

-

X-coordinate of intersection of the ellipse (mm)

- \( \tilde{x} \) :

-

Dimensionless length (–)

- \( y* \) :

-

Y-coordinate of intersection of the ellipse (mm)

- z :

-

Z-direction (–)

- \( \alpha \) :

-

Structure density (–)

- \(\eta \) :

-

Dynamic viscosity [\(\hbox {Ns}/\hbox {m}^{-2}\)].

- \(\tau _L(x)\) :

-

Frictional shear stress (MPa mm)

- \(\lambda \) :

-

Texture aspect ratio (–)

- \(\mu \) :

-

Coefficient of friction (–)

References

Trauth D, Feuerhack A, Mattfeld P, Klocke F (2015) Analysis of the velocity distribution of an elliptic surface structure manufactured by machine hammer peening. Tribol Lett 60(19):1–13. doi:10.1007/s11249-015-0595-1

Trauth D, Klocke F, Schongen F, Shirobokov A (2013) Analyse und Modellierung der Schlagkraft beim elektro-dynamischen Festklopfen zur kraftbasierten Prozessauslegung. UTFSci 3:1–8

Steitz M, Scheil J, Müller C, Groche P (2013) Effect of process parameters on surface roughness in hammer peening and deep rolling. Key Eng Mat 554–557:1887–1901. doi:10.4028/www.scientific.net/KEM.554-557.1887

Klocke F, Trauth D, Schongen F, Terhorst M (2013) Time-efficient process design of machine hammer peening—prediction of the surface layer state using similitude theory. Wt Online 10:758–763

Scheil J, Müller C, Steitz M, Groche P (2013) Influence of process parameters on surface hardening in hammer peening and deep rolling. Key Eng Mat 554–557:1819–1827. doi:10.4028/www.scientific.net/KEM.554-557.1819

Wied J (2011) Oberflächenbehandlung von Umformwerkzeugen durch Festklopfen. PHD-Thesis, Darmstadt

Lienert F, Hoffmeister J, Schulze V (2013) Residual stress depth distribution after piezo peening of quenched and tempered AISI 4140. Mat Sci Forum 768–769:526–533. doi:10.4028/www.scientific.net/MSF.768-769.526

Löcker C (2006) Working, smoothing and cold-hardening of the surface of tools, machine parts or other parts comprises hammering the surface with an electromagnetically controlled hammer head. German Patent DE102006033004A1

Löcker C (2012) Method and device for the technique of cold microforging any freely formed 3D surfaces. United States Patent US 8 166 793 B2

Bleicher F, Lechner C, Habersohn C, Kozeschnik E, Adjassoho B, Kaminiski H (2012) Mechanism of surface modification using machine hammer peening technology. CIRP Annals - Manuf Technol 61(1):375–378. doi:10.1016/j.cirp.2012.03.139

Bleicher F, Lechner C, Habersohn C, Obermair M, Heindl F, Ripoll MR (2013) Improving the tribological characteristics of tool and mould surfaces by machine hammer peening. CIRP Annals - Manuf Technol 62(1):239–242. doi:10.1016/j.cirp.2013.03.043

Ripoll MR, Heindl F, Lechner C, Habersohn C, Jech M, Bleicher F (2014) Improving wear resistance of functional surfaces using the machine hammer peening technique. Tribol Mat Surf Interf 8(1):21–26. doi:10.1179/1751584X14Y.0000000063

Lechner C, Bleicher F, Habersohn C, Bauer C, Goessinger S (2012) The use of machine hammer peening for smoothing and structuring of surfaces. Annals DAAAM 23(1):1–6

Trauth D, Klocke F, Welling D, Terhorst M, Mattfeld P, Klink A (2015) Investigation of the surface integrity and fatigue strength of Inconel718 after wire EDM and machine hammer peening. Int J Mater Forming, online first

Steitz M, Philipp S, Groche P (2015) Influence of Hammer–Peened surface textures on friction behavior. Tribol Lett 58(24):1–8. doi:10.1007/s11249-015-0502-9

Klocke F, Trauth D, Schongen F, Shirobokov A (2014) Analysis of friction between stainless steel sheets and machine hammer peened structured tool surfaces: experimental and numerical investigation of the lubricated interaction gap. Prod Eng 8(3):263–272. doi:10.1007/s11740-013-0519-6

Klocke F, Trauth D, Terhorst M, Mattfeld P (2014) Wear analysis of tool surfaces structured by machine hammer peening for foil-free forming of stainless steel. Adv Mater Res 1018:317–324. doi:10.4028/www.scientific.net/AMR.1018.317

Trauth D, Klocke F, Terhorst M, Mattfeld P (2015) Physicochemical analysis of machine hammer peened surface structures for deep drawing: determination of the work of adhesion and spreading pressure of lubrication to surface structure. J Tribol 137(2):1–7. doi:10.1115/1.4029199

Reynolds O (1927) Theorie der Schmiermittelreibung. In: Ostwald W (ed) Ostwalds Klassiker der exakten Wissenschaften. Akademische Verlagsgesellschaft, Leipzig, p 218

Bower GS (1946) Film lubrication of parallel thrust surfaces. Proc Inst Mech Eng 155:49

OMFRS Lord Rayleigh (1918) Notes on the theory of lubrication. Phil Mag J Sci 35:1–12. doi:10.1080/14786440108635730

Kettleborough CF (1961) An approximate analytical solution for the stepped bearing. J Appl Mech 28(4):507–510. doi:10.1115/1.3641775

Charnes A, Saibel E (1952) On the solution of the Reynolds equation for slider-bearing lubrication I. Trans ASME 74:867–873

Frössel W (1961) Berechnung axialer Gleitlager mit balligen Gleitflächen. Konstruktion 13:253–67

Charnes A, Saibel E, Ying ASC (1953) On the solution of the Reynolds equation for slider-bearing lubrication III. Effect of transverse curvature. Trans ASME 75:507–513

Raimondi AA (1960) The influence of longitudinal and transverse profil on the load capacity of pivoted pad bearings. Trans ASLE 3(2):265–276. doi:10.1080/05698196008972412

Wilcock DF (1955) The hydrodynamic pocket bearing. Trans ASME 77:311–319

Kettleborough CF (1956) The hydrodynamic pocket thrust-bearing. Proc Inst Mech Eng 170:535–544. doi:10.1243/PIME_PROC_1956_170_055_02

Brizmer V, Kligerman Y, Etison I (2003) A laser surface textured parallel thrust bearing. Tribol Trans 46(3):397–403. doi:10.1080/10402000308982643

Brizmer V, Kligerman Y (2012) A laser surface textured journal bearing. J Tribol 134(3):031702–031702-9. doi:10.1115/1.4006511

Dobrica MB, Fillon M (2006) Thermohydrodynamic behavior of a slider pocket bearing. J Tribol 128(2):312–328. doi:10.1115/1.2162914

Dobrica MB, Fillon M, Pascovici MD, Cicone T (2010) Optimizing surface texture for hydrodynamic lubricated contacts using a mass-conserving numerical approach. Proc Inst Mech Eng Part J: J Eng Tribol 224(8):737–750. doi:10.1243/13506501JET673

Ramesh A, Akram W, Mishra SP, Cannon AH, Polycarpou AA, King WP (2013) Friction characteristics of microtextured surfaces under mixed and hydrodynamic lubrication. Tribol Int 57(1):170–6. doi:10.1016/j.triboint.2012.07.020

Dobrica MB, Fillon M (2009) About the validity of Reynolds equation and inertia effects in textured sliders of infinite width. Proc Inst Mech Eng Part J: J Eng Tribol 223(1):69–78

Ausas R, Ragot P, Leiva J, Jai M, Bayada G, Buscaglia GC (2007) The impact of cavitation model in the analysis of microtextured lubricated journal bearings. J Tribol 129:868–875

Wang H, Yang S, Guo F (2011) Modeling of a grooved parallel bearing with a mass-conserving cavitation algorithm. Tribol Trans 64:227–236

Xiong S, Wang JQ (2012) Steady-State hydrodynamic lubrication modeled with the payvar-salant mass conservation model. J Tribol 134(3)

Gherca AR, Maspeyrot P, Hajjam M, Fatu A (2013) Influence of texture geometry on the hydrodynamic performances of parallel bearings. Tribol Trans 56:321–332

Rahmani R, Shirvani A, Shirvani H (2008) Optimization of partially textured parallel thrust bearings with square-shaped micro-dimples. Trib Trans 50:401–406

Khonsari MM, Booser ER (2008) Applied tribology: bearing design and lubrication. Wiley, Hoboken

Gohar R (2001) Elastohydrodynamics. World Scientific, Singapore

Dowson D, Taylor CM (1979) Cavitation in bearings. Anual Rev Fluid Mech 11(1):35–65

Acknowledgments

This work was partly supported by the European Union, Investing in our Future, European Regional Development Fund within the Initiative ’Ziel2.NRW’ [Grant Number: 21060207612] and the German Research Foundation (DFG) [Grant Number: KL 500/135-1].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Trauth, D., Stanke, J., Shirobokov, A. et al. Analysis of the fluid pressure, load capacity, and coefficient of friction of an elliptic machine hammer peened surface structure in hydrodynamic lubrication. Prod. Eng. Res. Devel. 10, 539–550 (2016). https://doi.org/10.1007/s11740-016-0696-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-016-0696-1