Abstract

During the manufacturing process of carbon fiber reinforced plastics, residual stresses and shape distortions occur. Analytical or numerical models can be employed to accurately predict these stresses and deformations. For a virtual compensation of a part’s geometry, an understanding of the main driving mechanisms behind process-induced distortions is essential. The present study shows main sources as well as influencing factors on stresses and distortions that arise during large-scale production of composites based on thermoset resin systems. Besides basic information on the thermal, chemical and mechanical behavior of thermoset resins and carbon fibers, state-of-the-art numerical approaches are reviewed with a focus on finite element discretization and constitutive modeling. Current virtual compensation strategies as well as possible influences of the forming operation are discussed. Finally, a conclusion is drawn that includes recommendations for future developments in the field of process-induced distortions.

Similar content being viewed by others

References

Industrievereinigung Verstärkte Kunststoffe e.V (2010) Handbuch Faserverbundkunststoffe. Vieweg and Teubner

Roll K, Lemke T, Wiegand K, Smith LM, Pourboghrat F, Cao J, Stoughton TB, Yoon J-W, Shi MF, Wang C-T, et al (2005) Possibilities and strategies for simulations and compensation for springback. AIP Conf Proc 778(1):295–302

Neitzel M, Mitschang P, Breuer U (2014) Handbuch Verbundwerkstoffe: Werkstoffe, Verarbeitung, Anwendung. Carl Hanser Verlag GmbH Co KG

Tucker N, Lindsey K (2002) An introduction to automotive composites. iSmithers Rapra Publishing

Schürmann H (2005) Konstruieren mit Faser-Kunststoff-Verbunden. Springer

Aronhime MT, Gillham JK (1986) Time-temperature-transformation (TTT) cure diagram of thermosetting polymeric systems. In: Epoxy Resins and Composites III. Springer, pp 83–113

Khoun L (2009) Process-induced stresses and deformations in woven composites manufactured by resin transfer moulding. Dissertation, McGill University

Brady R (1992) Recent advances in the development of expanding monomers: synthesis, polymerization and volume change. J Macromol Sci-Rev Macromol Chem Phys C 32:135–181

Mallick PK (2007) Fiber-reinforced composites: materials, manufacturing and design. CRC press

Wisnom M, Gigliotti M, Ersoy N, Campbell M, Potter K (2006) Mechanisms generating residual stresses and distortion during manufacture of polymer-matrix composite structures. Compos Part A Appl Sci Manuf 37(4):522–529

Albert C, Fernlund G (2002) Spring-in and warpage of angled composite laminates. Compos Sci Technol 62(14):1895–1912

Radford D, Rennick T (2000) Separating sources of manufacturing distortion in laminated composites. J Reinf Plast Compos 19(8):621–641

Flemming M, Roth S (2013) Faserverbundbauweisen Eigenschaften: mechanische, konstruktive, thermische, elektrische, ökologische, wirtschaftliche Aspekte, Bd. 4. Springer-Verlag

Kim J-K, Mai Y-W (1998) Engineered interfaces in fiber reinforced composites. Elsevier

Shimbo M, Ochi M, Shigeta Y (1981) Shrinkage and internal stress during curing of epoxide resins. J Appl Poly Sci 26(7):2265–2277

Ersoy N, Tugutlu M (2010) Cure kinetics modeling and cure shrinkage behavior of a thermosetting composite. Polym Eng Sci 50(1):84–92

Nelson RH, Cairns D (1989) Prediction of dimensional changes in composite laminates during cure. Tomorrow’s Mater Today 34:2397–2410

Ersoy N, Potter K, Wisnom MR, Clegg MJ (2005) Development of spring-in angle during cure of a thermosetting composite. Compos A Appl Sci Manuf 36(12):1700–1706

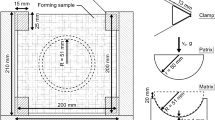

Wijskamp S (2005) Shape distortions in composites forming. Dissertation, University of Twente

Cho M, Kim M-H, Choi HS, Chung CH, Ahn K-J, Eom YS (1998) A study on the room-temperature curvature shapes of unsymmetric laminates including slippage effects. J Compos Mater 32(5):460–482

Gigliotti M, Jacquemin F, Vautrin A (2005) On the maximum curvatures of 0/90 plates under thermal stress. Compos Struct 68(2):177–184

Radford D, Diefendorf R (1993) Shape instabilities in composites resulting from laminate anisotropy. J Reinf Plast Compos 12(1):58–75

Hyer M, Rousseau C, Tompkins S (1988) Thermally induced twist in graphite-epoxy tubes. J Eng Mater Technol 110(2):83–88

Prasatya P, McKenna GB, Simon SL (2001) A viscoelastic model for predicting isotropic residual stresses in thermosetting materials: effects of processing parameters. J Compos Mater 35(10):826–848

Twigg G, Fernlund G, Poursartip A (2001) Measurement of tool-part interfacial stress during the processing of composite laminates. In: Sixteenth Technical Conference of the American Society for Composites

Twigg G, Poursartip A, Fernlund G (2004) Tool-part interaction in composites processing. Part I: experimental investigation and analytical model. Compos A Appl Sci Manuf 35(1):121–133

Khoun L, Hubert P (2010) Investigation of the dimensional stability of carbon epoxy cylinders manufactured by resin transfer moulding. Compos A Appl Sci Manuf 41(1):116–124

Spröwitz T, Huehne C, Kappel E (2009) Thermal aspects for composite structures—from manufacturing to in-service predictions. In: CEAS 2009 European Air and Space Conference

Bogetti TA, Gillespie JW (1992) Process-induced stress and deformation in thick-section thermoset composite laminates. J Compos Mater 26(5):626–660

Ruiz E, Trochu F (2005) Numerical analysis of cure temperature and internal stresses in thin and thick RTM parts. Compos A Appl Sci Manuf 36(6):806–826

Radford DW (1993) Cure shrinkage induced warpage in flat uni-axial composites. J Compos Tech Res 15(4):290–296

Radford DW (1995) Volume fraction gradient induced warpage in curved composite plates. Compos Eng 5(7):923–927

Yang S, Huang C, Chen C (2003) Effect of processing on precision of composite panels. Mater Manuf Process 18(5):769–781

Causse P, Ruiz E, Trochu F (2012) Spring-in behavior of curved composites manufactured by Flexible Injection. Compos A Appl Sci Manuf 43(11):1901–1913

Wisnom MR, Potter KD, Ersoy N (2007) Shear-lag analysis of the effect of thickness on spring-in of curved composites. J Compos Mater 41(11):1311–1324

Wiersma H, Peeters L, Akkerman R (1998) Prediction of springforward in continuous-fibre/polymer L-shaped parts. Compos A Appl Sci Manuf 29(11):1333–1342

Patterson JM, Springer GS, Kollar LP (1991) Experimental observations of the spring-in phenomenon. In: Eighth International Conference on Composite Materials

Kim C-G, Kim T-W, Kim I-G, Jun E-J (1989) Spring-in deformation of composite laminated bends. In: Proceedings of the 7th international conference on composite materials (ICCM7), Bd. 83-8

Zhu Q, Geubelle PH, Li M, Tucker CL III (2001) Dimensional accuracy of thermoset composites: simulation of process-induced residual stresses. J Compos Mater 35(24):2171–2205

Ochinero T, Hyer M (2001) Warpage of large curved composite panels due to manufacturing anomalies. In: Sixteenth Technical Conference of the American Society for Composites

Long A, Clifford M (2007) Composite forming mechanisms and material characterisation. Compos Form Technol, pp 1–21

Mesogitis T, Skordos AA, Long A (2015) Stochastic simulation of the influence of fibre path variability on the formation of residual stress and shape distortion. Polym Compos

Lamers EAD (2004) Shape distortions in fabric reinforced composite products due to processing induced fibre reorientation. Dissertation, University of Twente

Huang C, Yang S (1997) Warping in advanced composite tools with varying angles and radii. Compos A Appl Sci Manuf 28(9–10):891–893

Kappel E, Stefaniak D, Spröwitz T, Hühne C (2011) A semi-analytical simulation strategy and its application to warpage of autoclave-processed CFRP parts. Compos A Appl Sci Manuf 42(12):1985–1994

Sarrazin H, Kim B, Ahn S-H, Springer GS (1995) Effects of processing temperature and layup on springback. J Compos Mater 29(10):1278–1294

Sun L, Pang S-S, Sterling AM, Negulescu II, Stubblefield MA (2002) Dynamic modeling of curing process of epoxy prepreg. J Appl Polym Sci 86(8):1911–1923

White S, Hahn H (1993) Cure cycle optimization for the reduction of processing-induced residual stresses in composite materials. J Compos Mater 27(14):1352–1378

Kollår LP (1994) Approximate analysis of the temperature induced stresses and deformations of composite shells. J Compos Mater 28(5):392–414

Jain LK, Mai Y-W (1996) On residual stress induced distortions during fabrication of composite shells. J Reinf Plast Compos 15(8):793–805

Yoon K, Kim J-S (2001) Effect of thermal deformation and chemical shrinkage on the process induced distortion of carbon/epoxy curved laminates. J Compos Mater 35(3):253–263

Johnston A, Vaziri R, Poursartip A (2001) A plane strain model for process-induced deformation of laminated composite structures. J Compos Mater 35(16):1435–1469

Çınar K, Ersoy N, Öz F (2012) 3D process modelling for distortions in manufacturing of polymer composite materials. In: 15th European Conference on Composite Materials

Roozbehjavan P, Tavakol B, Ahmed A, Koushyar H, Das R, Joven R, Minaie B (2014) Experimental and numerical study of distortion in flat, L-shaped, and U-shaped carbon fiber-epoxy composite parts. J Appl Polym Sci 131. https://doi.org/10.1002/app.40439

Wang J, Kelly D, Hillier W (2000) Finite element analysis of temperature induced stresses and deformations of polymer composite components. J Compos Mater 34(17):1456–1471

Dassault Systèmes (2013) Abaqus analysis user’s guide (6.13)

Jain LK, Mai Y-W (1997) Stresses and deformations induced during manufacturing. Part I: theoretical analysis of composite cylinders and shells. J Compos Mater 31(7):672–695

Bapanapalli SK, Smith LV (2005) A linear finite element model to predict processing-induced distortion in FRP laminates. Compos A Appl Sci Manuf 36(12):1666–1674

Amann C, Kreissl S, Grass H, Meinhardt J, Merklein M (2016) Industrial distortion simulation of fibre reinforced plastics - a study on finite element discretisation. Adv Mater Res 1140:272–279

Chachad Y, Roux J, Vaughan J, Arafat E (1995) Three-dimensional characterization of pultruded fiberglass-epoxy composite materials. J Reinf Plast Compos 14(5):495–512

Arrhenius S (1889) Über die Reaktionsgeschwindigkeit bei der Inversion von Rohrzucker durch Säuren. Zeitschrift für physikalische Chemie 4(1):226–248

DiBenedetto A (1987) Prediction of the glass transition temperature of polymers: a model based on the principle of corresponding states. J Polym Sci Part B Polym Phys 25(9):1949–1969

Nawab Y, Shahid S, Boyard N, Jacquemin F (2013) Chemical shrinkage characterization techniques for thermoset resins and associated composites. J Mater Sci 48(16):5387–5409

Li C, Potter K, Wisnom MR, Stringer G (2004) In-situ measurement of chemical shrinkage of MY750 epoxy resin by a novel gravimetric method. Compos Sci Technol 64(1):55–64

Darrow DA, Smith LV (2002) Isolating components of processing induced warpage in laminated composites. J Compos Mater 36(21):2407–2419

Nielsen MW (2012) Prediction of process induced shape distortions and residual stresses in large fibre reinforced composite laminates. Dissertation, Technical University of Denmark

Brinson HF, Brinson LC (2008) Polymer engineering science and viscoelasticity. Springer

Baran I, Cinar K, Ersoy N, Akkerman R, Hattel JH (2016) A review on the mechanical modeling of composite manufacturing processes. Arch Comput Methods Eng 24(2):365–395

Svanberg JM, Holmberg JA (2004) Prediction of shape distortions Part I. FE-implementation of a path dependent constitutive model. Compos A Appl Sci Manuf 35(6):711–721

Svanberg JM, Holmberg JA (2004) Prediction of shape distortions. Part II. Experimental validation and analysis of boundary conditions. Compos A Appl Sci Manuf 35(6):723–734

Ding A, Li S, Wang J, Ni A, Sun L, Chang L (2016) Prediction of process-induced distortions in L-shaped composite profiles using path-dependent constitutive law. Appl Compos Mater 23(5):1027–1045

Ding A, Li S, Sun J, Wang J, Zu L (2016) A comparison of process-induced residual stresses and distortions in composite structures with different constitutive laws. J Reinf Plast Compos 35(10):807–823

Johnston AA (1997) An integrated model of the development of process-induced deformation in autoclave processing of composite structures. Dissertation, University of British Columbia

Baran I, Hattel JH, Tutum C (2013) The impact of process parameters on the residual stresses and distortions in pultrusion. In: Proceedings of 19th International Conference on Composite Materials

Voigt W (1889) Über die Beziehung zwischen den beiden Elastizitätsconstanten isotroper Körper. Wiedemanns Annalen der Physik 274(12):573–587

Reuss A (1929) Berechnung der Fließgrenze von Mischkristallen auf Grund der Plastizitätsbedingung für Einkristalle. Zeitschrift für Angewandte Mathematik und Mechanik 9(1):49–58

Chamis CC (1989) Mechanics of composite materials: past, present, and future. J Compos Tech Res 11(1):3–14

Mori T, Tanaka K (1973) Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall 21(5):571–574

Hill R (1965) Theory of mechanical properties of fibre-strengthened materials-III. Self-consistent model. J Mech Phys Solids 13(4):189–198

Huang Z-M (2001) Simulation of the mechanical properties of fibrous composites by the bridging micromechanics model. Compos A Appl Sci Manuf 32(2):143–172

Younes R, Hallal A, Fardoun F, Chehade FH (2012) Comparative review study on elastic properties modeling for unidirectional composite materials. In: Composites and their properties. intech

Karadeniz ZH, Kumlutas D (2007) A numerical study on the coefficients of thermal expansion of fiber reinforced composite materials. Compos Struct 78(1):1–10

Chamis CC (1984) Simplified composite micromechanics equations for strength, fracture toughness, impact resistance and environmental effects. In: NASA TM-83696

Gereke T, Döbrich O, Hübner M, Cherif C (2013) Experimental and computational composite textile reinforcement forming: a review. Compos A Appl Sci Manuf 46:1–10

Sweeting R, Liu X, Paton R (2002) Prediction of processing-induced distortion of curved flanged composite laminates. Compos Struct 57(1):79–84

Lamers E, Wijskamp S, Akkerman R (2004) Modelling shape distortions in composite products. Langmuir

Hein R, Wille T, Gabtni K, Dias J-P (2015) Prediction of process-induced distortions and residual stresses of a composite suspension blade. Defect Diffus Forum 362:224–243

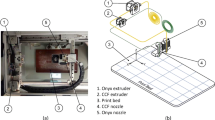

Dix M (2016) Eine durchgängig virtuelle Faserverbundprozesskette am Beispiel des RTM Prozesses. Dissertation, Technische Universität München

Amann C, Liebold C, Kreissl S, Grass H, Meinhardt J, Merklein M (2016) Berücksichtigung der umformbedingten Faser-Reorientierung bei der Verzugssimulation von CFK-Bauteilen. In: 14. Deutsches LS-DYNA Forum

Huang C, Yang S (1997) Study on accuracy of angled advanced composite tools. Mater Manuf Process 12(3):473–486

Fernlund G, Floyd A, McKay S (2007) Process analysis and tool compensation for curved composite L-angles. In: The 6th Canadian international composites conference

Zhu Q, Geubelle PH (2002) Dimensional accuracy of thermoset composites: shape optimization. J Compos Mater 36(6):647–672

Wucher B, Lani F, Pardoen T, Bailly C, Martiny P (2014) Tooling geometry optimization for compensation of cure-induced distortions of a curved carbon/epoxy C-spar. Compos A Appl Sci Manuf 56:27–35

Capehart T, Muhammad N, Kia HG (2007) Compensating thermoset composite panel deformation using corrective molding. J Compos Mater 41(14):1675–1701

Mezeix L, Seman A, Nasir M, Aminanda Y, Rivai A, Castanie B, Olivier P, Ali KM (2015) Spring-back simulation of unidirectional carbon/epoxy flat laminate composite manufactured through autoclave process. Compos Struct 124:196–205

Ghiasi H, Rahmat M, Hubert P, Lessard L (2009) Curved composite structures and compromise between process-induced deformations and structural performance. In: 18th international conference on composite materials

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amann, C., Kreissl, S., Grass, H. et al. A review on process-induced distortions of carbon fiber reinforced thermosets for large-scale production. Prod. Eng. Res. Devel. 11, 665–675 (2017). https://doi.org/10.1007/s11740-017-0772-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-017-0772-1