Abstract

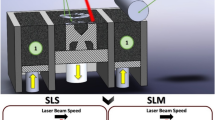

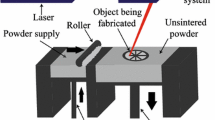

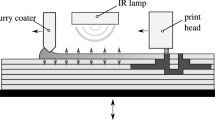

Due to their flexibility to also build up highly complex geometries, Additive Manufacturing (AM) processes are increasingly applied. Although near net-shape components can be manufactured using, for example, the Selective Laser Melting (SLM) process, the required surface quality can often not be achieved. In order to manufacture contact areas or functional surfaces, subsequent machining processes can be used to achieve the required accuracy in shape and dimension as well as the desired surface quality. In order to reduce the experimental effort during process design and optimization, simulation systems that are able to efficiently model both processes are required. In this paper, an empirical geometry-based model for SLM and milling processes will be presented. Due to the usage of an empirical model, based on the analysis of a set of reference structures, the simulation of macroscopic geometries can be achieved and used in subsequent milling simulations. Furthermore, an experimental validation of the combination of the two simulation models will be presented.

Similar content being viewed by others

References

Uhlmann E, Kersting R, Klein TB, Cruz MF, Borille AV (2015) Additive manufacturing of titanium alloy for aircraft components. Procedia CIRP 35:55–60

Thompson MK, Moroni G, Vaneker T, Fadel G, Campbell RI, Gibson I, Bernard A, Schulz J, Graf P, Ahuja B et al (2016) Design for additive manufacturing: trends, opportunities, considerations, and constraints. CIRP Ann Manuf Technol 65(2):737–760

Strano G, Hao L, Everson RM, Evans KE (2013) Surface roughness analysis, modelling and prediction in selective laser melting. J Mater Process Technol 213(4):589–597

Levy GN, Schindel R, Kruth J-P (2003) Rapid manufacturing and rapid tooling with layer manufacturing (lm) technologies, state of the art and future perspectives. CIRP Ann Manuf Technol 52(2):589–609

Yasa E, Poyraz O, Solakoglu EU, Akbulut G, Oren S (2016) A study on the stair stepping effect in direct metal laser sintering of a nickel-based superalloy. Procedia CIRP 45:175–178

Markl M, Körner C (2016) Multiscale modeling of powder bed-based additive manufacturing. Annu Rev Mater Res 46:93–123

Kruth J-P, Levy G, Klocke F, Childs T (2007) Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann Manuf Technol 56(2):730–759

Rombouts M, Kruth J-P, Froyen L, Mercelis P (2006) Fundamentals of selective laser melting of alloyed steel powders. CIRP Ann Manuf Technol 55(1):187–192

Liu Y, Yang Y, Wang D (2017) Investigation into the shrinkage in z-direction of components manufactured by selective laser melting (slm). Int J Adv Manuf Technol 90(9–12):2913–2923

Craeghs T, Clijsters S, Kruth J-P, Bechmann F, Ebert M-C (2012) Detection of process failures in layerwise laser melting with optical process monitoring. Phys Procedia 39:753–759

Zaeh MF, Branner G (2010) Investigations on residual stresses and deformations in selective laser melting. Prod Eng 4(1):35–45

Riedlbauer D, Steinmann P, Mergheim J (2015) Thermomechanical simulation of the selective laser melting process for pa12 including volumetric shrinkage. In: AIP conference proceedings, vol 1664, pp 160005. AIP Publishing

San Sebastian M, Setien I, Mancisidor AM, Echeverria A (2017) Slm (near)-net-shape part design optimization based on numerical prediction of process induced distortions. In: TMS 2017 146th annual meeting & exhibition supplemental proceedings, pp 117–126. Springer

Brinksmeier E, Levy G, Meyer D, Spierings A (2010) Surface integrity of selective-laser-melted components. CIRP Ann Manuf Technol 59(1):601–606

Ahmed N, Abdo BM, Darwish S, Moiduddin K, Pervaiz S, Alahmari AM, Naveed M (2017) Electron beam melting of titanium alloy and surface finish improvement through rotary ultrasonic machining. Int J Adv Manuf Technol 92(9–12):3349–3361

Salonitis K, D’Alvise L, Schoinochoritis B, Chantzis D (2016) Additive manufacturing and post-processing simulation: laser cladding followed by high speed machining. Int J Adv Manuf Technol 85(9–12):2401–2411

Flynn JM, Shokrani A, Newman ST, Dhokia V (2016) Hybrid additive and subtractive machine tools-research and industrial developments. Int J Mach Tools Manuf 101:79–101

Milton S, Morandeau A, Chalon F, Leroy R (2016) Influence of finish machining on the surface integrity of ti6al4v produced by selective laser melting. Procedia CIRP 45:127–130

Montevecchi F, Grossi N, Takagi H, Scippa A, Sasahara H, Campatelli G (2016) Cutting forces analysis in additive manufactured aisi h13 alloy. Procedia CIRP 46:476–479

Fortunato A, Lulaj A, Melkote S, Liverani E, Ascari A, Umbrello D (2017) Milling of maraging steel components produced by selective laser melting. Int J Adv Manuf Technol 94(5–8):1895–1902

Oyelola O, Crawforth P, M’Saoubi R, Clare AT (2016) Machining of additively manufactured parts: implications for surface integrity. Procedia CIRP 45:119–122

Altintas Y, Kersting P, Biermann D, Budak E, Denkena B, Lazoglu I (2014) Virtual process systems for part machining operations. CIRP Ann Manuf Technol 63(2):585–605

Wiederkehr P, Siebrecht T (2016) Virtual machining: capabilities and challenges of process simulations in the aerospace industry. Procedia Manuf 6:80–87

Röttger A, Geenen K, Windmann M, Binner F, Theisen W (2016) Comparison of microstructure and mechanical properties of 316l austenitic steel processed by selective laser melting with hot-isostatic pressed and cast material. Mater Sci Eng A 678:365–376

Wits WW, Bruins R, Terpstra L, Huls RA, Geijselaers H (2016) Single scan vector prediction in selective laser melting. Addit Manuf 9:1–6

Bridson R (2007) Fast poisson disk sampling in arbitrary dimensions. In: SIGGRAPH sketches, p 22

Peytavie A, Galin E, Grosjean J, Mérillou S (2009) Procedural generation of rock piles using aperiodic tiling. In: Computer graphics forum, vol 28, pp 1801–1809. Wiley Online Library

Wiederkehr T, Müller H (2013) Acquisition and optimization of three-dimensional spray footprint profiles for coating simulations. J Therm Spray Technol 22(6):1044–1052

Heeling T, Cloots M, Wegener K (2017) Melt pool simulation for the evaluation of process parameters in selective laser melting. Addit Manuf 14:116–125

Acknowledgements

The authors would like to thank K. Geenen, A. Röttger and W. Theisen from the Chair of Materials Technology (LWT, RUB) for providing the specimens for the slot milling tests and the SLM Solutions Group AG for manufacturing the test workpiece.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wiederkehr, P., Bergmann, J.A. An integrated macroscopic model for simulating SLM and milling processes. Prod. Eng. Res. Devel. 12, 465–472 (2018). https://doi.org/10.1007/s11740-018-0822-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-018-0822-3