Abstract

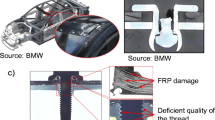

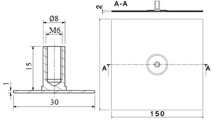

Due to their outstanding specific mechanical properties, carbon fibre reinforced plastics (CFRP) exhibit a high application potential for lightweight structures. With respect to multi-material design and to avoid drilling of structural CFRP parts to join them to other components, embedded metal elements, so called inserts, can be used. The inserts consist of a shaft and a baseplate which is embedded between the fibre layers. So far, only punctiform inserts have been subject to research. One feasible geometry are linear inserts which have not been studied yet. In this work, the performance of two different types of linear inserts will be investigated. The shapes are based on a punctiform insert which is made out of a threaded shaft welded onto a baseplate whose performance under different types of loading has been investigated before. The first type of linear inserts has the same cross-section as the reference punctiform insert but is of a linear form. The second type is a quasi-linear insert which consists of a baseplate with the same dimensions as the first linear inserts and three threaded shafts welded onto it. All samples are manufactured by resin transfer moulding (RTM). Depending on the geometry of the insert and the preforming concept it is potentially possible to maintain the fibre continuity. For the inserts with a continuous shaft and in the proximity of the insert, it is necessary to cut fibres of the top layers which are aligned perpendicular to the shaft. For the quasi-linear insert, it is possible to maintain the fibre continuity as the fibres are guided around the circular shafts. Additional to mechanical tests that are carried out, mould-filling and curing simulations are performed for different inserts to analyse the influence of the process parameters onto the part quality. In the main series of tests, the specimens are characterized regarding their failure behaviour and load bearing capacity under quasi-static loads. The results of the experiments show that, compared to the punctiform reference insert, the linear load introduction elements exhibit higher load bearing capacity. However, the linear load introduction elements are inferior regarding specific load bearing capacity and furthermore increase process complexity during preforming and production.

Similar content being viewed by others

References

Eriksson I (1990) On the bearing strength of bolted graphite/epoxy laminates. J Compos Mater 24(12):1246–1269

Camanho PP, Lambert M (2006) A design methodology for mechanically fastened joints in laminated composite materials. Compos Sci Technol 66(15):3004–3020

Xiao Y, Ishikawa T (2005) Bearing strength and failure behavior of bolted composite joints (part I). Compos Sci Technol 65(7):1022–1031

Kolesnikov B, Herbeck L, Fink A (2008) CFRP/titanium hybrid material for improving composite bolted joints. Compos Struct 83(4):368–380

Gebhardt J, Fleischer J (2014) Experimental investigation and performance enhancement of inserts in composite parts. Procedia CIRP 23:7–12

Ferret B, Anduze M, Nardari C (1998) Metal inserts in structural composite materials manufactured by RTM. Compos Part A: Appl Sci Manufac 29(5–6):693–700

Hopmann C, Fecher ML, Lineman L, Bastian R, Gries T, Schnabel A, Greb C (2013) Comparison of the properties of onserts and inserts for a high volume production of structural composite parts. J Plast Technol 9(4):179–206

Fleischer J, Gebhardt J (2013)Experimental investigation of metal inserts embedded in composite parts manufactured by the RTM process. In: 13th Japan International SAMPE Symposium and Exhibition, Nagoya, Japan

Schwarz M, Magin M, Peil C, Schurmann H (2004) Thin-walled FRP-laminates and local bending moments-incompatible or solvable by a skillful design. In: Internationale Tagung für Verstärkte Kunststoffe und Duroplastische Formmasse, pp 28–29

Gebhardt J, Pottmeyer F, Fleischer J, Weidenmann K (2015) Characterization of metal inserts embedded in carbon fiber reinforced plastics. Mater Sci Forum 825–826:506–513

Soliman E, Al-Haik M, Taha MR (2012) On and off-axis tension behavior of fiber reinforced polymer composites incorporating multi-walled carbon nanotubes. J Compos Mater 46(14):1661–1675

Ferguson RF, Hinton MJ, Hiley MJ (1998) Determining the through-thickness properties of FRP materials. Compos Sci Technol 58(9):1411–1420

Gebhardt J (2016) Strukturoptimierung von in FVK eingebetteten metallischen Lasteinleitungselementen, Shaker Verlag, Herzogenrath

Pottmeyer F, Weispfenning M, Weidenmann KA (2016) Research of the load bearing capacity of inserts embedded in CFRP under different loading conditions. World Acad Sc Eng Technol Intl J Chem Mol Nucl Mater Metall Eng 11(1):1–8

Wilkening J, Pottmeyer F, Weidenmann KA (2016) Research on the interfering effect of metal inserts in carbon fiber reinforced plastics manufactured by the RTM process. In: 17th European Conference on Composite Materials, Munich, Germany

Magagnato D, Frey M, Bernath A, Steibler P, Henning F (2013) Experimentelle und numerische Untersuchung der Infiltration bei der RTM-Fertigung. In: A. Wanner, K. Weidenmann (Eds.) Verbundwerkstoffe und Werkstoffverbunde. Karlsruhe Institute of Technology, Karlsruhe

Seuffert J, Kärger L, Henning F (2017) Simulation of the influence of embedded inserts on the RTM filling behavior considering local fiber structure. KEM, Destin, 742 pp 681–688. https://doi.org/10.4028/www.scientific.net/KEM.742.681

Abbassi A, Shahnazari MR (2004) Numerical modeling of mold filling and curing in non-isothermal RTM process. Appl Therm Eng 24(16):2453–2465. https://doi.org/10.1016/j.applthermaleng.2004.03.005

Lim ST, Lee WI (2000) An analysis of the three-dimensional resin-transfer mold filling process. Compos Sci Technol 60(7):961–975. https://doi.org/10.1016/S0266-3538(99)00160-8

Lin RJ, Lee LJ, Liou MJ (1993) Mold filling and curing analysis in liquid composite molding. Polym Compos 14(1):71–81. https://doi.org/10.1002/pc.750140111

Shojaei A (2003) Simulation of the three-dimensional non-isothermal mold filling process in resin transfer molding. Compos Sci Technol 63(13):1931–1948. https://doi.org/10.1016/S0266-3538(03)00161-1

Young W-B (1994) Three-dimensional nonisothermal mold filling simulations in resin transfer molding. Polym Compos 15(2):118–127. https://doi.org/10.1002/pc.750150205

Halley PJ, Mackay ME (1996) Chemorheology of thermosets? Polym Eng Sci 36(5):593–609. https://doi.org/10.1002/pen.10447

Magagnato D, Henning F (2015) Process-oriented determination of preform permeability and matrix viscosity during mold filling in resin transfer molding. Mater Sci Forum 825–829:822–829. https://doi.org/10.4028/www.scientific.net/MSF.825-826.822

Bernath A, Kärger L, Henning F (2016) Accurate cure modeling for isothermal processing of fast curing epoxy resins. Polymers 8(11):390. https://doi.org/10.3390/polym8110390

Kamal MR, Sourour S, Ryan ME (1973) Integrated thermo-rheological analysis of the cure of thermosets. SPE Tech Pap(19):187

Castro JM, Macosko CW (1982) Studies of mold filling and curing in the reaction injection molding process. AIChE J 28(2):250–260. https://doi.org/10.1002/aic.690280213

Muth M, Pottmeyer F, Weidenmann KA (2016) Investigation of the failure behavior of metal inserts embedded in CFRP under cyclic loading. Int J Eng Res Sci 2(10):71–86

Pottmeyer F, Bittner J, Pinter P, Weidenmann KA (2017) In-Situ CT damage analysis of metal inserts embedded in carbon fiber-reinforced plastics. Exp Mech 57(9):1411–1422

Acknowledgements

This paper is based on investigations of the subproject 3—“Fundamental research of intrinsically produced FRP-/metal-composites—from embedded insert to load bearing hybrid structure”—of the priority program 1712 “Intrinsic hybrid composites for lightweight load-bearings”, which is kindly supported by the German Research Foundation (DFG).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Muth, M., Schwennen, J., Bernath, A. et al. Numerical and experimental investigation of manufacturing and performance of metal inserts embedded in CFRP. Prod. Eng. Res. Devel. 12, 141–152 (2018). https://doi.org/10.1007/s11740-018-0829-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-018-0829-9