Abstract

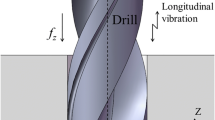

In this paper, monitoring of amplitude variation in the torsional–axial frequency is proposed for evaluating drill flank wear. Vibration signals were captured from the experiments resulting to the drilling process and investigation was focused on the role of torsional–axial coupling on instability predictions arising as a result of drill flank wear in the frequency spectrum. The first and second modes of torsional axial coupling frequencies were found through use of finite element analysis (FEA) and verified using experimental modal analysis (EMA) by the resonance frequency test. The proposed strategy uses dominant peaks of torsional–axial first mode (Tp1) and second mode (Tp2) frequency. The ratio of torsional–axial amplitudes (TP1/TP2) was considered for the monitoring and the evaluation of drill wear and also to nullify process parameter variation. Drill frequencies verified through experimental study showed their capability of predicting drill flank wear. The validation showed the proposed methodology having 80% accuracy and its ability for effective use for monitoring tool wear.

Similar content being viewed by others

References

Subramanian K, Cook NH (1977) Sensing of drill wear and prediction of drill life. ASME J Eng Ind 99:529–551

Noori-Khajavi A, Komanduri R (1995) Frequency and time domain analyses of sensor signals in drilling-II. Investigation on some problems associated with sensor integration. Int J Mach Tools Manuf 35(6):795–815

Antić A, Popović B, Krstanović L, Obradović R, Milošević M (2018) Novel texture-based descriptors for tool wear condition monitoring. Mech Syst Signal Process 98:1–15

Ertunc HM, Loparo KA (2001) A decision fusion algorithm for tool wear condition monitoring in drilling. Int J Mach Tools Manuf 41:1347–1362

Klaic M, Staroveski T, Udiljak T (2014) Tool wear classification using decision trees in stone drilling applications: a preliminary study. Procedia Eng 69:1326–1335

Nouri M, Fussell BK, Ziniti BL, Linder E (2015) Real-time tool wear monitoring in milling using a cutting condition independent method. Int J Mach Tools Manuf 89:1–13

Teti R, Jemielniak K, O’Donnell G, Dornfeld D (2010) Advanced monitoring of machining operations. Ann CIRP Manuf Technol 59:717–739

Bombinskia S, Blazejaka K, Nejmana M, Jemielniaka K (2016) Sensor signal segmentation for tool condition monitoring. Procedia CIRP 46:155–160

Ratava J, Lohtander M, Varis J (2017) Tool condition monitoring in interrupted cutting with acceleration sensors. Roboti Comput Integr Manuf 47:70–75

Roukema JC, Altindas Y (2004) Kinematic model of dynamic drilling process. In: IMECE 2004–59340 ASME international mechanical engineering congress, Anaheim, California

Tlusty J, Ismail F (1981) Basic nonlinearity in machining chatter. Ann CIRP 30(1):299–304

Tekinalp O, Ulsoy AG (1990) Effects of geometric and process parameters on drill transverse vibrations. ASME J Eng Ind 112:189–194

Roukema JC, Altindas Y (2007) Generalized modeling of drilling operations. Part II: chatter stability in frequency domain. Int J Mach Tools Manuf 47:1474–1485

Arvajeh T, Ismail F (2006) Machining stability in high speed drilling-part 2: time domain simulation of a bending—torsional model and experimental validations. Int J Mach Tools Manuf 46:1573–1581

Imani BM, Moosavi SG (2009) Time domain simulation of torsional–axial and lateral vibration in drilling operation. In: Proceedings of ICADME, Malaysia, 9G1-9G7

Roukema JC, Altindas Y (2006) Time domain Simulation of torsional–axial vibrations in drilling. Int J Mach Tools Manuf 46(15):2073–2085

Irvine T (2000) An introduction to frequency response functions. Vibrationdata.com Publications, Englewood Cliffs

Arvajeh T, Ismail F (2006) Machining stability in high speed drilling-part 1: modeling vibration stability in bending. Int J Mach Tools Manuf 46:1563–1572

Nakandhrakumar RS, Dinakaran D, Gopal M, Pattabiraman J (2016) A novel normalization procedure for the sensor positioning problem in vibration monitoring of drilling using artificial neural networks. Insight 58(10):556–563

Rajeev D, Dinakaran D, Singh SCE (2017) Artificial neural network based tool wear estimation on dry hard turning processes of AISI4140 steel using coated carbide tool. Bull Pol Acad Technol 65(4):553–559

Yang Y, Zhang WH, Ma YC, Wan M (2015) Generalized method for the analysis of bending, torsional and axial receptances of tool-holder-spindle assembly. Int J Mach Tools Manuf 99:48–67

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nakandhrakumar, R.S., Dinakaran, D., Pattabiraman, J. et al. Tool flank wear monitoring using torsional–axial vibrations in drilling. Prod. Eng. Res. Devel. 13, 107–118 (2019). https://doi.org/10.1007/s11740-018-0866-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-018-0866-4