Abstract

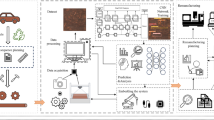

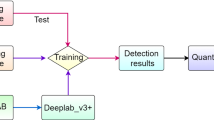

Wood defect identification plays an essential role in guaranteeing the quality and efficiency of furniture manufacturing, which is a challenging task due to the data complexity and high-efficiency requirements. This paper proposes an improved ResNet-50-based modeling method to enhance the accuracy and efficiency of defect identification on wood surfaces. Firstly, a new optimization scheme integrating a convolutional block attention module and the cross-stage partial network (CSPNet) was developed for ResNet-50. Besides, the impacts of cross-stage parameter in CSPNet’s classification performance are experimentally investigated, and it is demonstrated that the default cross-stage parameter in CSPNet is not always optimal. Furthermore, a ranger optimizer is proposed to obtain proper network parameters, which outperforms the traditional Adam optimizer with respect to training efficiency and prediction accuracy. Experiments are carried out on the image dataset collected from real-world wood surface defects. The experimental results illustrated that the proposed model achieves better defects on wood surfaces than state-of-the-art methods, with an overall detection accuracy of 86.25% in detecting knots, cracks, and color-related defects in images. These results demonstrate the effectiveness and feasibility of the proposed modeling and control method.

Similar content being viewed by others

Data availability

The datasets used or analysed during the current study are available from the corresponding author on reasonable request.

References

Lerm, F.J., Blumentritt, M., Brink, W.H., Wessels, C.B.: A method for three-dimensional stem analysis and its application in a study on the occurrence of resin pockets in Pinus patula. Eur. J. Forest Res. 136(3), 411–420 (2017)

Jones, T.G., Downes, G.M., Watt, M.S., Kimberley, M.O., Culvenor, D.S., Ottenschlaeger, M., Estcourt, G., Xue, J.M.: Effect of stem bending and soil moisture on the incidence of resin pockets in radiata pine. N. Z. J. Forest. Sci. 43, 10 (2013)

Pan, L., Rogulin, R., Kondrashev, S.: Artificial neural network for defect detection in CT images of wood. Comput. Electron. Agric. 187, 106312 (2021)

Mousavi, M., Gandomi, A.H.: Wood hole-damage detection and classification via contact ultrasonic testing. Constr. Build. Mater. 307, 124999 (2021)

Radwan, M., Thiel, D.V., Espinosa, H.G.: Single-sided microwave near-field scanning of pine wood lumber for defect detection. Forests 12(11), 1486 (2021)

Hashim, U.R., Hashim, S.Z., Muda, A.K.: Automated vision inspection of timber surface defect: a review. J. Teknol. 77(20), 127–135 (2015)

Ersbøll, B.K., Conradsen, K.: Automated grading of wood slabs: the development of a prototype system. Ind. Metrol. 2(3), 219–236 (1992)

Hashim, U.R.A., Hashim, S.Z.M., Muda, A.K., Kanchymalay, K., Jalil, I.E.A., Anuar, A.N., Othman, M.H.: Extraction and exploratory analysis of texture features on images of timber defect. Adv. Sci. Lett. 24(2), 1104–1108 (2018)

Silvén, O., Niskanen, M., Kauppinen, H.: Wood inspection with non-supervised clustering. Mach. Vis. Appl. 13(5), 275–285 (2003)

Riana, D., Rahayu, S., Hasan, M., Anton: Comparison of segmentation and identification of swietenia mahagoni wood defects with augmentation images. Heliyon 7(6), e07417 (2021)

Mériaudeau, F., Beya, O., Sidibé, D., Hittawe, M.M.: Machine vision for timber grading singularities detection and applications. J. Electron. Imaging 26(06), 063015 (2017)

Kamal, K., Qayyum, R., Mathavan, S., Zafar, T.: Wood defects classification using laws texture energy measures and supervised learning approach. Adv. Eng. Inform. 34, 125–135 (2017)

Zhang, Y., Xu, C., Li, C., Yu, H., Cao, J.: Wood defect detection method with PCA feature fusion and compressed sensing. J. For. Res. 26(3), 745–751 (2015)

Breinig, L., Leonhart, R., Broman, O., Manuel, A., Brüchert, F., Becker, G.: Classification of wood surfaces according to visual appearance by multivariate analysis of wood feature data. J. Wood Sci. 61(2), 89–112 (2014)

Gao, M., Qi, D., Mu, H., Chen, J.: A transfer residual neural network based on ResNet-34 for detection of wood knot defects. Forests 12(2), 212 (2021)

Gao, M., Song, P., Wang, F., Liu, J., Mandelis, A., Qi, D., Yang, R.: A novel deep convolutional neural network based on ResNet-18 and transfer learning for detection of wood knot defects. J. Sens. 2021, 1–16 (2021)

Li, D., Xie, W., Wang, B., Zhong, W., Wang, H.: Data augmentation and layered deformable mask R-CNN-based detection of wood defects. IEEE Access 9, 108162–108174 (2021)

Urbonas, A., Raudonis, V., Maskeliūnas, R., Damaševičius, R.: Automated identification of wood veneer surface defects using faster region-based convolutional neural network with data augmentation and transfer learning. Appl. Sci. 9(22), 4898 (2019)

He, T., Liu, Y., Yu, Y., Zhao, Q., Hu, Z.: Application of deep convolutional neural network on feature extraction and detection of wood defects. Measurement 152, 107357 (2020)

Hu, J., Song, W., Zhang, W., Zhao, Y., Yilmaz, A.: Deep learning for use in lumber classification tasks. Wood Sci. Technol. 53(2), 505–517 (2019)

Ren, R., Hung, T., Tan, K.C.: A generic deep-learning-based approach for automated surface inspection. IEEE Trans. Cybern. 48(3), 929–940 (2018)

Woo, S., Park, J., Lee, J.Y., Kweon, I.S.: Cbam: convolutional block attention module. In: Proceedings of the European Conference on Computer Vision (ECCV), pp. 3–19 (2018)

Wang, C.Y., Liao, H.Y.M., Wu, Y.H., Chen, P.Y., Hsieh, J.W., Yeh, I.H.: CSPNet: a new backbone that can enhance learning capability of CNN. In: Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition Workshops, pp. 390–391 (2020)

Kodytek, P., Bodzas, A., Bilik, P.: A large-scale image dataset of wood surface defects for automated vision-based quality control processes. F1000Research 10, 581 (2021)

Fabijańska, A., Danek, M., Barniak, J., Piórkowski, A.: Towards automatic tree rings detection in images of scanned wood samples. Comput. Electron. Agric. 140, 279–289 (2017)

Funding

This work was supported by the Jiangxi Provincial Department of Education Science and Technology Research Project (Grant Nos. GJJ190505 and GJJ200867), the Natural Science Foundation of Jiangxi Province (Grant Nos. 20212BAB212004 and 20224BAB202025) and the Municipal Key R&D Program of Ganzhou (Grant No. GSKF[2019]60).

Author information

Authors and Affiliations

Contributions

WU performed the experiments. ZOU and WU wrote the manuscript and analyzed the data. LIU designed the experiments, revised the manuscript and analyzed the data. YU analyzed the data. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zou, X., Wu, C., Liu, H. et al. Improved ResNet-50 model for identifying defects on wood surfaces. SIViP 17, 3119–3126 (2023). https://doi.org/10.1007/s11760-023-02533-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11760-023-02533-y