Abstract

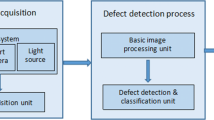

The defects in the metal coating surface of annular ceramic workpiece have significant effects on the conductivity and reliability. Due to the irregularity, small area, and few sample number of defects, it is difficult to achieve efficient and accurate inspection. This paper presents a defect inspection framework based on deep learning for the metal coating surface of annular ceramic workpiece. Firstly, an image acquisition system for the coating surface is designed, and the defects characteristics are analyzed. Then, a surface image data set is constructed through five data augmentation strategies in order to solve the problem of insufficient samples. Finally, a defect detection framework based on improved YOLOv7 for Ceramic Metal Coating (YOLOV7-CMC) is established. By optimizing the clustering algorithm of target box, introducing an attention mechanism, and improving the MPConv structure, the efficient and precise identification of different defects is realized. Experimental results show that the recognition rate of defects including scratch, deficiency, scuffing, and dot is higher than 94%, and the average detection time is about 30 ms. The proposed detection framework based on deep learning shows great application potential in the fields of precise coating and manufacturing of ceramic materials.

Similar content being viewed by others

Data availability

No datasets were generated or analysed during the current study.

References

Heidarzadeh, A., Taherzadeh Mousavian, R., Brabazon, D.: Manufacturing of copper coated sic ceramic particles for metal matrix composites: optimizing the electroless deposition parameters. Mater Rrs Express (2018). https://doi.org/10.1088/2053-1591/aadace

Landahl, S., Terry, L.: Detection of internal defects in onion bulbs by means of single-point and scanning laser Doppler vibrometry. Biosyst Eng 221, 258–273 (2022)

Sun, J., Li, C., Wu, X.J., Palade, V., Fang, W.: An effective method of weld defect detection and classification based on machine vision. IEEE Trans. Industr. Inf. 15, 6322–6333 (2019)

Lee, W.K., Ratnam, M., Ahmad, Z.: Detection of fracture in ceramic cutting tools from workpiece profile signature using image processing and fast Fourier transform. Precis. Eng. 44, 131–142 (2016)

Kim, K.B., Song, D.H.: Automatic defect detection using fuzzy binarization and brightness contrast stretching from ceramic images for non-destructive testing. Kiice. 21, 2121–2127 (2017)

Chen, X., Zhang, Y., Lin, L., Wang, J.X., Ni, J.: Efficient anti-glare ceramic decals defect detection by incorporating homomorphic filtering. Comput. Syst. Sci. Eng. 36, 551–564 (2021)

Chen, T., Dac-Nhuong, L., Zhang, X., Jiang, Z.T., Zheng, Q., Wu, N.X.: Detection method based on a coupled illumination correction algorithm for the detection of surface defects in ZrO2 ceramic bearing balls. Appl. Opt. 61, 7813–7819 (2022)

Huang, W.Z., Zhang, C., Wu, X., Shen, J.Y., Li, Yuan: The detection of defects in ceramic cell phone backplane with embedded system. Measurement 181, 109598 (2021)

Nogay, H., Akinci, T., Yilmaz, M.: Detection of invisible cracks in ceramic materials using by pre-trained deep convolutional neural network. Neural Comput. Appl. 34, 1423–1432 (2022)

Lu, Q.H., Lin, J.M., Luo, L.F., Zhang, Y.Z., Zhu, W.B.: A supervised approach for automated surface defect detection in ceramic tile quality control. Adv. Eng. Inform. 53, 101692 (2022)

Chen, W., Zou, B., Huang, C.Z., Yang, J.Z., Li, L., Liu, J.K., Wang, X.F.: The defect detection of 3D-printed ceramic curved surface parts with low contrast based on deep learning. Ceram Int 49, 2881–2893 (2023)

Wang, C.Y., Bochkovskiy, A., Liao, H.: YOLOv7: Trainable bag-of-freebies sets new state-of-the-art for real-time object detectors, ArXiv. (2022).

Ghiasi, G., Cui, Y., Srinivas, A., Qian, R., Lin, T., Cubuk, E.D., Le, Q.V., Zoph, B.: Simple Copy-Paste is a strong data augmentation method for instance segmentation, 2021 IEEE/CVF Conference on computer vision and pattern recognition (CVPR), Nashville, TN, USA, 2021.

Lin, T., Maire, M., Belongie, S., Hays, J., Perona, P., Ramanan, D., Dollar, P., Zitnick, C. L.: Microsoft COCO: Common objects in context, European conference on computer vision (2014).

Ge, Z., Liu, S.T., Wang, F., Li, Z.M., Sun, J.: YOLOX: exceeding YOLO series in2021, ArXiv. (2021).

Ding, X.H., Zhang, X., Ma, N.N., Han, J.G., Ding, G., Sun, J.: RepVGG: Making VGG-style ConvNets Great Again, 2021 IEEE/CVF Conference on computer vision and pattern recognition (CVPR), Nashville, TN, USA, 2021

Sun, Z., Yang, Q., Yan, N., Chen, Si.: Utilizing deep learning algorithms for automated oil spill detection in medium resolution optical imagery. Marine Pollution Bulletin, 206 (2024).

Xu, X., Wang, H., Miao, M., Zhang, W.: Cucumber flower detection based on YOLOv5s-SE7 within greenhouse environments, IEEE Access, 11 (2023).

Qin, X.Y., Li, N., Weng, C., Su, D., Li, M.: Simple attention module based speaker verification with iterative noisy label detection, ICASSP 2022 - 2022 IEEE International conference on acoustics, speech and signal processing (ICASSP), Singapore, Singapore, 2022.

Ismkhan, H.: I-k-means−+: An iterative clustering algorithm based on an enhanced version of the k-means. Pattern Recogn. 79, 402–413 (2018)

Wang, C.Y., Bochkovskiy, A., Liao, H.: YOLOv7: Trainable bag-of-freebies sets new state-of-the-art for real-time object detectors, 2023 IEEE/CVF conference on computer vision and pattern recognition (CVPR), (2023).

Ren, S., He, K., Girshick, R., Sun, J.: Faster R-CNN: towards real-time object detection with region proposal networks, IEEE transactions on pattern analysis and machine intelligence, (2017)

Liu, Z., Lin, Y., Cao, Y., Hu, H., Wei, Yi.: Swin Transformer: Hierarchical Vision Transformer using Shifted Windows, 2021 IEEE/CVF International Conference on Computer Vision (ICCV), Montreal, QC, Canada, 2021.

Jia, X., Li, S., Wang, T., Liu, B., Cui, C., Li, W., Wang, G.: high-performance defect detection methods for real-time monitoring of ceramic additive manufacturing process based on small-scale datasets, Processes. (2024).

Funding

Public Welfare Technology Research Project of Zhejiang Natural Science Foundation, LY23E050005, Ningbo Technology Innovation 2035 Project,2024Z167

Author information

Authors and Affiliations

Contributions

Jia Le Chu and Dan LIANG proposed the main idea of the paper, and wrote the main manuscript text. Yong Long Xi and Min Jie Ye made substantial contributions to the acquisition and interpretation of data, and the revision of the paper. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chu, J.L., Liang, D., Xi, Y.L. et al. Surface inspection of annular ceramic metal coating based on small sample data augmentation and deep learning. SIViP 19, 46 (2025). https://doi.org/10.1007/s11760-024-03710-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11760-024-03710-3