Abstract

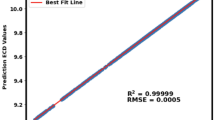

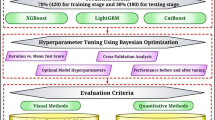

Mud-logging data, including drilling data (DD) and gas while drilling (GWD) parameters, are recorded in every oil and gas well drilled and are available for real-time assessment making them more beneficial for prompt assessment of formation assessment than the higher cost data provided by cores and wireline or measurement-while-drilling logs. The novel contribution of this research is that integrates DD and GWD data, to enhance prediction performance of formation bulk density in real time during drilling operations, It achieves this using interpretable machine learning Shapley Additive exPlanations (SHAP) analysis combined with four gradient-boosting models (CatBoost, Adaptive Boosting (AdaBoost), Light Gradient Boosting Machine (LightGBM) and Extreme Gradient Boosting (XGBoost)) applied to data collected from two productive Algerian fields: Sif Fatima undersaturated (gas-poor) oil reservoir and Oued Zine saturated (gas-rich) oil reservoir. The results show that the DD and GWD inputs could effectively predict bulk density in both gas-poor and gas-rich oil reservoirs with various levels of precision. For gas-poor oil reservoirs, DD inputs, used in isolation generate predictions with low errors, particularly with model CatBoost4 (R≈0.905, RMSE≈0.040 g/cm3, MAE≈0.018 g/cm3, NSE≈0.815). For the gas-rich oil reservoir, DD inputs also achieved low errors (R≈0.945, RMSE≈0.025 g/cm3, MAE≈0.012 g/cm3, NSE≈0.845). However, the bulk formation density predictions of these reservoirs were better using GWD data in isolation (e.g., model CatBoost5: R≈0.991, RMSE≈0.009 g/cm3, MAE≈0.005 g/cm3, NSE≈0.980). These results are consistent with the expectations of gas-saturated oil reservoirs, as reported for real time porosity predictions. Good prediction performance was also achieved for the gas-rich oil reservoir by integrating both GWD and DD inputs, particularly with model AdaBoost:2 (R ≈ 0.985. RMSE ≈0.012 g/cm3, MAE≈0.009 g/cm3, NSE≈0.962). This investigation confirms that the use of Drilling Data (DD) is more effective for predicting bulk density in gas-poor reservoirs, while predictions using Gas While Drilling (GWD) data are more accurate in gas-rich reservoirs,This study also confirms the potential for real time bulk formation density predictions using mud logging parameters, justifying the compilation of larger datasets and comparing results from a wide range of reservoir formations and fluid types.

Highlights

• DD reliably predicts bulk density for gas-rich and gas-poor oil reservoirs.

• DD sensitivity analyses are distinctive for oil and gas-rich oil reservoirs.

• GWD provides the best bulk density prediction in gas-rich oil reservoirs.

• SHAP is an effective tool for interpreting input parameter prediction impacts.

• Mud logging data can reliably predict bulk density in different reservoirs.

Similar content being viewed by others

Data availability

No datasets were generated or analyzed during the current study.

Abbreviations

- ANFIS:

-

Adaptive Neuro-Fuzzy Inference System

- ANN:

-

Artificial Neural Network

- C1:

-

Methane

- C2:

-

Ethane

- C3:

-

Propane

- DD:

-

Drilling Data

- EML:

-

Extreme Machine Learning

- FN:

-

Functional Networks

- GQR:

-

Gas Quality Ratio

- GWD:

-

Gas While Drilling

- iC4:

-

Isobutane

- iC5:

-

Iso-pentane

- LightGBM:

-

Light Gradient Boosting Machine

- MAE:

-

Mean Absolute Error

- ML:

-

Machine Learning

- nC4:

-

N-Butane

- nC5:

-

N-Pentane

- NSE:

-

Nash-Sutcliffe Efficiency

- RMSE:

-

Root Mean Square Error

- R:

-

Correlation Coefficient

- ROP:

-

Rate of Penetration

- RF:

-

Random Forest

- RPM:

-

Revolutions Per Minute

- SHAP:

-

SHapley Additive exPlanations

- SPP:

-

Standpipe Pressure

- SVM:

-

Support Vector Machine

- WOB:

-

Weight on Bit

- XGBoost:

-

Extreme Gradient Boosting

References

Abdullah EC, Geldart D (1999) The use of bulk density measurements as flowability indicators. Powder Technol 102(2):151–165. https://doi.org/10.1016/S0032-5910(98)00208-3

Agrawal R, Malik A, Samuel R, Saxena A (2021) Real-time prediction of Litho-facies from drilling data using an artificial neural network: a comparative field data study with optimizing algorithms. J Energy Resour Technol 1–22. https://doi.org/10.1115/1.4051573

Agrawal R, Malik A, Samuel R, Saxena A (2022) Comparative study of homogeneous ensemble methods with conventional ML classifiers in litho-facies detection using real-time drilling data. Arab J Geosci 15(23):1732

Ahmadi MA, Chen Z (2019) Comparison of machine learning methods for estimating permeability and porosity of oil reservoirs via petro-physical logs. Petroleum 5(3):271–284. https://doi.org/10.1016/j.petlm.2018.06.002

Ahmed A, Elkatatny S, Alsaihati A (2021) Applications of artificial intelligence for static Poisson’s ratio prediction while drilling. Comput Intell Neurosci 2021. https://doi.org/10.1155/2021/9956128

Ahmed A, Elkatatny S, Gamal H, Abdulraheem A (2022a) Artificial intelligence models for real-time bulk density prediction of vertical complex lithology using the drilling parameters. Arab J Sci Eng 47(9):10993–11006. https://doi.org/10.1007/s13369-021-05537-3

Ahmed A, Gamal H, Elkatatny S, Ali A (2022b) Bulk density prediction while drilling vertical complex lithology using artificial intelligence. J Appl Geophys 199:104574. https://doi.org/10.1016/j.jappgeo.2022.104574

Al-Jamimi HA, Al-Azani S, Saleh TA (2018) Supervised machine learning techniques in the desulfurization of oil products for environmental protection: a review. Process Saf Environ Prot 120:57–71. https://doi.org/10.1016/j.psep.2018.08.021

Al-Jamimi HA, BinMakhashen GM, Saleh TA (2022) Multiobjectives optimization in petroleum refinery catalytic desulfurization using Machine learning approach. Fuel 322:124088. https://doi.org/10.1016/j.fuel.2022.124088

Alkinani HH, Al-Hameedi ATT, Dunn-Norman S (2020) Artificial neural network models to predict lost circulation in natural and induced fractures. SN Appl Sci 2:1–13. https://doi.org/10.1007/s42452-020-03827-3

Al-Mudhafar W (2018a) Bayesian and LASSO regressions for comparative permeability modeling of sandstone reservoirs. Nat Resour Res 28:47–62. https://doi.org/10.1007/s11053-018-9370-y

Al-Mudhafar WJ (2018b) Integrating lithofacies and well logging data into Smooth Generalized Additive Model for improved permeability estimation: Zubair formation, South Rumaila oil field. Marine Geophysical Research 40:315–332. https://doi.org/10.1007/s11001-018-9370-7

Alsabaa A, Gamal H, Elkatatny S, Abdulraheem A (2020) Real-time prediction of rheological properties of invert emulsion mud using adaptive neuro-fuzzy inference system. Sensors 20(6):1669

Alsaihati A, Elkatatny S (2021) Real-time prediction of acoustic velocities while drilling vertical complex lithology using AI technique. Petrophysics 62(03):265–281. https://doi.org/10.30632/PJV62N3-2021a2

Ameur-Zaimeche O, Kechiched R, Heddam S, Wood DA (2022) Real-time porosity prediction using gas-while-drilling data and machine learning with reservoir associated gas: case study for Hassi Messaoud field, Algeria. Mar Petrol Geol 140:105631. https://doi.org/10.1016/j.marpetgeo.2022.105631

Ameur-Zaimeche O, Zeddouri A, Heddam S, Kechiched R (2020) Lithofacies prediction in non-cored wells from the Sif Fatima oil field (Berkine basin, southern Algeria): a comparative study of multilayer perceptron neural network and cluster analysis-based approaches. J Afr Earth Sc 166:103826. https://doi.org/10.1016/j.jafrearsci.2020.103826

Anifowose F, Badawood S (2024a) Improved reservoir rock porosity prediction from advanced mud gas data. In: International Petroleum Technology Conference. IPTC, pp IPTC-23110

Anifowose F, Badawood S (2024b) Improved reservoir rock porosity prediction from advanced mud gas data. Paper presented at the International Petroleum Technology Conference, Dhahran, Saudi Arabia. https://doi.org/10.2523/IPTC-23110-EA

Anifowose F, Mezghani M, Badawood S, Ismail J (2022a) Contributions of machine learning to quantitative and real-time mud gas data analysis: a critical review. Appl Comput Geosci 16:100095. https://doi.org/10.1016/j.acags.2022.100095

Anifowose F, Mezghani M, Badawood S, Ismail J (2022b) A first attempt to predict reservoir porosity from advanced mud gas data. Paper IPTC-22061-MS. In: International Petroleum Technology Conference, p D021S042R001, Riyadh. IPTC

Anifowose F, Mezghani M, Badawood S, Ismail J (2023) From well to field: reservoir rock porosity prediction from advanced mud gas data using machine learning methodology. In: SPE Middle East Oil and Gas Show and Conference, p D011S033R004. https://doi.org/10.2118/213339-MS

Ashena R, Rabiei M, Rasouli V, Mohammadi AH, Mishani S (2021) Drilling parameters optimization using an innovative artificial intelligence model. J Energy Res Technol 143(5):052110. https://doi.org/10.1115/1.4050050

Bermingham ML, Pong-Wong R, Spiliopoulou A, Hayward C, Rudan I, Campbell H, ... Haley CS (2015) Application of high-dimensional feature selection: evaluation for genomic prediction in man. Sci Rep 5(1):10312

Chen Y, Zhao L, Pan J, Li C, Xu M, Li K, ... Geng J (2021) Deep carbonate reservoir characterisation using multi-seismic attributes via machine learning with physical constraints. J Geophys Eng 18(5):761–775. https://doi.org/10.1093/jge/gxab049

Dashti J, Al-Mulla K, Al-Kandari E, Al-Ajmi B, Rao S, Al-Qattan F, ... Janbakhsh M (2015) Use of mud gas chromatograph for reservoir quality prediction while drilling-a case study. In: SPE Kuwait oil and gas show and conference. SPE, pp SPE-175268. https://doi.org/10.2118/175268-MS

Djebbas F, Ameur-Zaimeche O, Kechiched R, Heddam S, Wood DA, Movahed Z (2023) Integrating hydraulic flow unit concept and adaptive neuro-fuzzy inference system to accurately estimate permeability in heterogeneous reservoirs: case study Sif Fatima oilfield, southern Algeria. J Afr Earth Sc 206:105027. https://doi.org/10.1016/j.jafrearsci.2023.105027

Donaldson EC, Chilingarian GV, Yen TF (eds) (1985) Enhanced oil recovery, I: fundamentals and analyses. Elsevier

Dorogush AV, Ershov V, Gulin A (2018) CatBoost: gradient boosting with categorical features support. arXiv preprint arXiv:1810.11363

Ekechukwu G, Adejumo A (2024) Explainable machine-learning-based prediction of equivalent circulating density using surface-based drilling data. Sci Rep 14(1):17780

Friedman JH (2002) Stochastic gradient boosting. Comput Stat Data Anal 38(4):367–378. https://doi.org/10.1016/S0167-9473(01)00065-2

Fryer D, Strümke I, Nguyen H (2021) Shapley values for feature selection: the good, the bad, and the axioms. Ieee Access 9:144352–144360

Gamal H, Alsaihati A, Elkatatny S, Haidary S, Abdulraheem A (2021) Rock strength prediction in real-time while drilling employing random forest and functional network techniques. J Energy Res Technol 143(9):093004. https://doi.org/10.1115/1.4050843

Gowida A, Elkatatny S, Abdulraheem A (2019) Application of artificial neural network to predict formation bulk density while drilling. Petrophysics 60(05):660–674. https://doi.org/10.30632/PJV60N5-2019a9

Gowida A, Elkatatny S, Abdulraheem A, Shehri DA (2020) Synthetic well-log generation: new approach to predict formation bulk density while drilling using neural networks and fuzzy logic. In: International Petroleum Technology Conference. IPTC, p D022S147R002. https://doi.org/10.2523/IPTC-19787-MS

GuolinKe QM, Finley T, Wang T, Chen W, Ma W, Ye Q, Liu TY (2017) Lightgbm: a highly efficient gradient boosting decision tree. Adv Neural Inf Process Syst 30:52

Hammerschmidt SB, Wiersberg T, Heuer VB, Wendt J, Erzinger J, Kopf A (2014) Real-time drilling mud gas monitoring for qualitative evaluation of hydrocarbon gas composition during deep sea drilling in the Nankai Trough Kumano Basin. Geochem Trans 15:1–15

He Y, Zhou Y, Wen T, Zhang S, Huang F, Zou X, ... Zhu Y (2022) A review of machine learning in geochemistry and cosmochemistry: method improvements and applications. Appl Geochem 140:105273. https://doi.org/10.1016/j.apgeochem.2022.105273

Ibrahim AF, Elkatatny S (2022) Real-time GR logs estimation while drilling using surface drilling data; AI application. Arab J Sci Eng 47(9):11187–11196

Jian SR, Zhang M, Chen B, Chen X, Wang Q, Li L, Ren L (2021) Identification of porosity and permeability while drilling based on machine learning. Arab J Sci Eng 46(7):7031–7045. https://doi.org/10.1007/s13369-021-05432-x

Kanfar R, Shaikh O, Yousefzadeh M, Mukerji T (2020) Real-time well log prediction from drilling data using deep learning. In: International Petroleum Technology Conference. OnePetro

Kharaka YK, Hanor JS (2003) Deep fluids in the continents: I. Sedimentary basins. Treatise on Geochemistry 5:605

Kuang L, He LIU, Yili REN, Kai LUO, Mingyu SHI, Jian SU, Xin LI (2021) Application and development trend of artificial intelligence in petroleum exploration and development. Pet Explor Dev 48(1):1–14. https://doi.org/10.1016/S1876-3804(21)60001-0

Legates DR, McCabe GJ Jr (1999) Evaluating the use of “goodness-of-fit” measures in hydrologic and hydroclimatic model validation. Water Resour Res 35(1):233–241. https://doi.org/10.1029/1998WR900018

Lundberg SM, Erion G, Chen H, DeGrave A, Prutkin JM, Nair B, Katz R, Himmelfarb J, Bansal N, Lee S-I (2019) Explainable AI for trees : from local explanations to global understanding (arXiv:1905.04610). arXiv. https://doi.org/10.48550/arXiv.1905.04610

Lundberg S, Lee S-I (2017) A unified approach to interpreting model predictions (arXiv:1705.07874). arXiv. https://doi.org/10.48550/arXiv.1705.07874

Mahmoud AA, Elkatatny S, Al-AbdulJabbar A (2021) Application of machine learning models for real-time prediction of the formation lithology and tops from the drilling parameters. J Petrol Sci Eng 203:108574. https://doi.org/10.1016/j.petrol.2021.108574

Mardanirad S, Wood DA, Zakeri H (2021) The application of deep learning algorithms to classify subsurface drilling lost circulation severity in large oil field datasets. SN Appl Sci 3(9):785. https://doi.org/10.1007/s42452-021-04769-0

Mavko G, Mukerji T, Dvorkin J (2020) The rock physics handbook. Cambridge University Press. https://doi.org/10.1017/9781108333016

McCarthy J (1981) Epistemological problems of artificial intelligence. In: Readings in artificial intelligence. Morgan Kaufmann, pp 459–465. https://doi.org/10.1016/B978-0-934613-03-3.50035-0

Moazzeni A, Haffar MA (2015) Artificial intelligence for lithology identification through real-time drilling data. J Earth Sci Clim Chang 6(3):1–4

Moriasi DN, Arnold JG, Van Liew MW, Bingner RL, Harmel RD, Veith TL (2007) Model evaluation guidelines for systematic quantification of accuracy in watershed simulations. Trans ASABE 50(3):885–900

Natekin A, Knoll A (2013) Gradient boosting machines, a tutorial. Front Neurorobot 7:21. https://doi.org/10.3389/fnbot.2013.00021

Ouladmansour A, Ameur-Zaimeche O, Kechiched R, Heddam S, Wood DA (2023) Integrating drilling parameters and machine learning tools to improve real-time porosity prediction of multi-zone reservoirs. Case study: Rhourd Chegga oilfield, Algeria. Geoenergy Sci Eng 223:211511. https://doi.org/10.1016/j.geoen.2023.211511

Pan S, Zheng Z, Guo Z, Luo H (2022) An optimized XGBoost method for predicting reservoir porosity using petrophysical logs. J Petrol Sci Eng 208:109520. https://doi.org/10.1016/j.petrol.2021.109520

Reitermanova Z (2010) Data splitting. In: WDS, vol 10. Matfyzpress, Prague, pp 31–36

Salehi MM, Rahmati M, Karimnezhad M, Omidvar P (2017) Estimation of the non records logs from existing logs using artificial neural networks. Egypt J Pet 26(4):957–968. https://doi.org/10.1016/j.ejpe.2016.11.002

Schober P, Boer C, Schwarte LA (2018) Correlation coefficients: appropriate use and interpretation. Anesth Analg 126(5):1763–1768

Siddig O, Gamal H, Elkatatny S, Abdulraheem A (2021) Real-time prediction of Poisson’s ratio from drilling parameters using machine learning tools. Sci Rep 11(1):12611

Spross R, Burnett T, Freeman J, Jones D, Paske W, Zannoni S (1993) Formation density measurement while drilling. In: SPWLA annual logging symposium. SPWLA, pp SPWLA-1993

Sun G, Zeng Q, Zhou JX (2022) Machine learning coupled with mineral geochemistry reveals the origin of ore deposits. Ore Geol Rev 142:104753. https://doi.org/10.1016/j.oregeorev.2022.104753

Ważny J, Stefaniuk M, Cygal A (2021) Estimation of electrical resistivity using artificial neural networks: a case study from Lublin Basin, SE Poland. Acta Geophys 69:631–642. https://doi.org/10.1007/s11600-021-00554-0

Wu CL, Zhou ZX, Ding TH, Xiong JG, Gao YL, Li Y, Luo XL (2023) Calibration technology and application of mud logging sensors based on artificial intelligence. In: International field exploration and development conference. Springer Nature Singapore, Singapore, pp 113–123

Wraight PD, Evans M, Marienbach E, Rhein-Knudsen E, Best D (1989) Combination formation density and neutron porosity measurements while drilling. In: SPWLA annual logging symposium. SPWLA, pp SPWLA-1989

Wright M, Nugroho C, Cherdasa JR, Prathidina R, Avrino A (2018) Advanced analysis of mud gas data helped identify oil and gas zones in wells with minimum logging data. In: SPWLA Asia Pacific Technical Symposium. SPWLA, pp SPWLA-2018

Yang T, Yerkinkyzy G, Uleberg K, Arief IH (2021) Predicting reservoir fluid properties from advanced mud gas data. SPE Reservoir Eval Eng 24(02):358–366

Zeng A, Yan L, Huang Y, Ren E, Liu T, Zhang H (2021) Intelligent detection of small faults using a support vector machine. Energies 14(19):6242. https://doi.org/10.3390/en14196242

Zhong R, Salehi C, Johnson Jr R (2022) Machine learning for drilling applications: a review. J Nat Gas Sci Eng 104807. https://doi.org/10.1016/j.jngse.2022.104807

Acknowledgements

We gratefully acknowledge the help provided by Mr. Nordin Meddour and all members of SONATRACH, Berkine Groupement, Algeria, for their help in collecting data.

Funding

There is no funding supported by any agency or organization.

Author information

Authors and Affiliations

Contributions

Ayoub Bouataghane: Data Curation, Conceptualization, Software, Writing-original draft preparation, Writing Review and Editing. Ouafi Ameur-Zaimeche: Supervision, Methodology, Software, Interpretation of the Results, Writing-original draft preparation, Writing Review and Editing. Salim Heddam: Supervision, Software, Investigation, Visualization, Writing Review and Editing. Rabah Kechiched: Interpretation of the Results, Writing-original draft preparation, Writing Review and Editing. Nasreddine Tahar-Belkacem: Software, Investigation, Visualization, Writing Review and Editing. Abdelhamid Ouladmansour: Software, Investigation, Visualization, Writing Review and Editing. Watheq J. Al-Mudhafar: Interpretation of the Results, Validation, Writing Review and Editing. David A. Wood: Interpretation of the Results, Validation, Writing Review and Editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Communicated by: Hassan Babaie

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Boutaghane, A., Ameur-Zaimeche, O., Heddam, S. et al. Enhancing formation bulk density prediction while drilling using mud logging data and interpretable boosting machine learning. Earth Sci Inform 18, 172 (2025). https://doi.org/10.1007/s12145-024-01642-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12145-024-01642-7