Abstract

Given the impact of transportation costs on both supplier selection and inventory replenishment decisions in today’s enterprises, this article addresses both problems simultaneously by proposing a mixed integer nonlinear programming model to properly allocate order quantities to the selected set of suppliers while taking into account the purchasing, holding and transportation costs under suppliers’ capacity and quality constraints. It is shown that incorporating transportation costs in the process of selecting suppliers and establishing an inventory policy, not only affects the order quantity shipped from selected suppliers, but also the actual selection of suppliers. Because of the difficulty that arises when working with actual transportation freight rates in large-scale problems, two continuous functions that estimate actual freight rates are analyzed. It is shown that the use of these functions is very practical and easy to implement.

Similar content being viewed by others

References

Ballou RH (2004) Business logistics/supply chain management, 5th edn. Pearson/Prentice Hall, Delhi/Upper Saddle River

Baumol WJ, Vinod H (1970) An inventory-theoretic model of freight transport demand. Manage Sci 16(7):413–421

Buffa FP, Reynolds JI (1977) The inventory-transport model with sensitivity analysis by indifference curves. Transp J 2(16):83–90

Carter JR, Ferrin BG (1996) Transportation costs and inventory management: why transportation costs matter. Prod Inventory Manag J 37(3):58–62

Das C (1974) Choice of transport service: an inventory theoretic approach. Logist Transp Rev 10(2):181–187

DiFillipo T (2003) Multi-criteria supply chain inventory models with transportation costs. Dissertation, Department of Industrial and Manufacturing Engineering, Pennsylvania State University, University Park, PA

GAMS Development Co (2009) GAMS on-line documentation. http://www.gams.com

Hughes Network Systems (2009) Routing guides: FOB terms. http://www.hughes.com

Johnson LA, Montgomery DC (1974) Operations research in production planning, scheduling, and inventory control. Wiley, NY

Langley CJ (1980) The inclusion of transportation costs in inventory models: some considerations. J Bus Logist 2(1):106–125

Larson PD (1988) The economic transportation quantity. Transp J 28(2):43–48

LINDO Systems (2009) LINGO documentation. http://www.lindo.com

Mendoza A, Ventura JA (2008) Modeling actual freight rates in the supplier selection and order quantity allocation problem. Working Paper, Department of Industrial and Manufacturing Engineering, Pennsylvania State University, University Park, PA

MINITAB (2009) Minitab 15 Documentation. http://www.minitab.com

Natarajan A (2007) Multi-criteria supply chain inventory models with transportation costs. Dissertation, Department of Industrial and Manufacturing Engineering, The Pennsylvania State University, University Park, PA

Rieksts BQ, Ventura JA (2008) Optimal inventory policies with two modes of freight transportation. Eur J Oper Res 186(2):576–585

Swenseth SR, Godfrey MR (1996) Estimating freight rates for logistics decisions. J Bus Logist 17(1):213–231

Swenseth SR, Godfrey MR (2002) Incorporating transportation costs into inventory replenishment decisions. Int J Prod Econ 77(2):113–130

Tyworth JE (1991) Transport selection: computer modeling in a spreadsheet environment. Int J Phys Distrib Logist Manag 21(7):28–36

Tyworth JE, Ruiz-Torres A (2000) Transportation’s role in the sole- versus dual-sourcing decision. Int J Phys Distrib Logist Manag 30(2):128–144

Tyworth J, Zeng A (1998) Estimating the effects of carrier transit-time performance on logistics cost and service. Transp Res 32(2):89–97

Walpole RE, Myers RH, Myers SL, Ye K (2002) Probability & Statistics for Engineers & Scientists, 7th edn. Pearson Education, Delhi

Warsing PD (2008) Supply chain management. In: Ravindran A (ed) Operations research and management science handbook. CRC Press, Boca Raton, pp 22–1–22–59

Acknowledgments

This research has been funded by a grant from the PSU/Technion Marcus Funds and the Ridg-U-Rak Honors Scholarship from the Material Handling Education Foundation.

Author information

Authors and Affiliations

Corresponding author

Appendix 1: Mendoza and Ventura’s model [13]

Appendix 1: Mendoza and Ventura’s model [13]

The mathematical model for supplier selection and order quantity allocation using actual transportation freight rates from Mendoza and Ventura [13] is presented in this appendix. With the exception of λi,k, bi,k, gi,k, which are introduced and explained below, the notation is the same as that used in the present article:

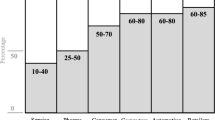

The total weight shipped from supplier ‘i’ (in one order) is defined in Eq. 21, where bi,k (i=1,…,r; k =1,…,u i +1) represents a break point (lb) that can be obtained from the actual LTL rate structure, and u i is the total number of break points in the actual LTL rate structure. Furthermore, bi,1 = 0 and \( b_{{i,u_{i} + 1}} \) equals the capacity of a TL. The total transportation cost charged to supplier i for the weight (Qw) shipped is defined in Eq. 22, where gi,k (i = 1,…,r; k =1,…,u i +1) is the total transportation cost obtained by evaluating the corresponding break point bi,k into the actual LTL rate structure. As per the definition of \( b_{{i,u_{i} + 1}} , \)\( g_{{i,u_{i} + 1}} \) is the cost of a full TL. Moreover, each binary variable, Zi,k, represents one linear segment of the freight rate function (see Fig. 3). By constraint 27, only one Zi,k per supplier can get a value of ‘1’. Then, the specific segment chosen contains the weight shipped (Qw) and its corresponding total transportation cost TC i (Qw) is expressed as the linear combination of λi,k and λi,k+1 (0 ≤ λi,k ≤ 1, i = 1,…,r; k = 1,…,ui + 1). This clearly explains the presence of constraints 23–27.

Rights and permissions

About this article

Cite this article

Mendoza, A., Ventura, J.A. Estimating freight rates in inventory replenishment and supplier selection decisions. Logist. Res. 1, 185–196 (2009). https://doi.org/10.1007/s12159-009-0018-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12159-009-0018-5