Abstract

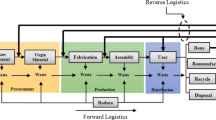

Green supply chain management is based on performing environmental management into supply chain network in order to decrease the environmental side effects in the product life cycle. So, in this paper, a bi-objective nonlinear programming for an integrated forward/reverse logistics network with the aim of increasing total profit of the network and maximizing the score of green design and quality indicators and green scrap score is discussed. Quality and green design indicators are considered for the forward network and the green scrap score are defined for scrapped products collected and disassembled in the reverse network. The mentioned network includes three echelons in the forward flow (production centers (factories), distribution centers, and customer zones) and three echelons in the reverse flow (collection/disassembly centers, recycling centers, and disposal centers). The main contribution of this study is to consider green design indicators and quality indicators for developing final products. Furthermore, in the model of this research, some constraints are regarded to determine the amount of paper and plastic consumption in the packaging of the products. After presenting the considered model, Multi-objective Particle Swarm Optimization and Non-dominated Sorting Genetic (NSGA-II) meta-heuristic Algorithms are proposed to find a set of Pareto-optimal solutions. Then, their output is compared through some samples with different sizes to prove their workability.

Similar content being viewed by others

References

Abu Seman NA, Zakuan N, Jusoh A, Shoki M (2012) Green supply chain management: a review and research direction. Int J Manag Value Supply Chains 3:1–18. https://doi.org/10.5121/ijmvsc.2012.3101

Alfonso-Lizarazo EH, Montoya-Torres JR, Gutiérrez-Franco E (2013) Modeling reverse logistics process in the agro-industrial sector: the case of the palm oil supply chain. Appl Math Model 37:9652–9664. https://doi.org/10.1016/j.apm.2013.05.015

Baumgarten H, Butz C, Fritsch A, Sommer-Dittrich T (2003) Supply chain management and reverse logistics-integration of reverse logistics processes into supply chain management approaches. In: 2003 IEEE international symposium on electronics and the environment, pp 79–83

Boks C, Stevels A (2007) Essential perspectives for design for environment. Experiences from the electronics industry. Int J Prod Res 45:4021–4039. https://doi.org/10.1080/00207540701439909

Coello Coello CA, Toscano Pulido G, Salazar Lechuga M (2004) Handling multiple objectives with particle swarm. Optimization. https://doi.org/10.1109/tevc.2004.826067

Coello Coello CA, Lamont GB, Van Veldhuizen DA (2007) Evolutionary algorithms for solving multi-objective problems, 2nd edn. Springer, US. https://doi.org/10.1007/978-0-387-36797-2

Deb K, Pratap A, Agarwal S (2002) A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans Evol Comput 6:182–197

Dimopoulos C, Zalzala AMS (2000) Recent developments in evolutionary computation for manufacturing optimization: problems, solutions, and comparisons. IEEE Trans Evol Comput 4:93–113

Dondo RG, Méndez CA (2016) Operational planning of forward and reverse logistic activities on multi-echelon supply-chain networks. Comput Chem Eng 88:170–184. https://doi.org/10.1016/j.compchemeng.2016.02.017

El-Sayed M, Afia N, El-Kharbotly A (2010) A stochastic model for forward–reverse logistics network design under risk. Comput Ind Eng 58:423–431. https://doi.org/10.1016/j.cie.2008.09.040

Entezaminia A, Heydari M, Rahmani D (2016) A multi-objective model for multi-product multi-site aggregate production planning in a green supply chain: considering collection and recycling centers. J Manuf Syst 40:63–75. https://doi.org/10.1016/j.jmsy.2016.06.004

Fleischmann M, Bloemhof-Ruwaard JM, Dekker R, van der Laan E, van Nunen JAEE, Van Wassenhove LN (1997) Quantitative models for reverse logistics: a review. Eur J Oper Res 103:1–17. https://doi.org/10.1016/S0377-2217(97)00230-0

Gaur J, Amini M, Rao AK (2017) Closed-loop supply chain configuration for new and reconditioned products: an integrated optimization model. Omega 66:212–223. https://doi.org/10.1016/j.omega.2015.11.008

Gen M, Altiparmak F, Lin L (2006) A genetic algorithm for two-stage transportation problem using priority-based encoding. OR Spectr 28:337–354. https://doi.org/10.1007/s00291-005-0029-9

Ghayebloo S, Tarokh MJ, Venkatadri U, Diallo C (2015) Developing a bi-objective model of the closed-loop supply chain network with green supplier selection and disassembly of products: the impact of parts reliability and product greenness on the recovery network. J Manuf Syst 36:76–86. https://doi.org/10.1016/j.jmsy.2015.02.011

Giarola S, Zamboni A, Bezzo F (2011) Spatially explicit multi-objective optimisation for design and planning of hybrid first and second generation biorefineries. Comput Chem Eng 35:1782–1797. https://doi.org/10.1016/j.compchemeng.2011.01.020

Govindan K, Soleimani H, Kannan D (2015) Reverse logistics and closed-loop supply chain: a comprehensive review to explore the future. Eur J Oper Res 240:603–626. https://doi.org/10.1016/j.ejor.2014.07.012

Jamshidi R, Fatemi Ghomi SMT, Karimi B (2012) Multi-objective green supply chain optimization with a new hybrid memetic algorithm using the Taguchi method. Sci Iran 19:1876–1886. https://doi.org/10.1016/j.scient.2012.07.002

Kazemi FS, Tavakkoli-Moghaddam R (2011) Solving a multi-objective multi-mode resource-constrained project scheduling problem with particle swarm optimization. Int J Acad Res 3:103–110

Lu Z, Bostel N (2007) A facility location model for logistics systems including reverse flows: the case of remanufacturing activities. Comput Oper Res 34:299–323. https://doi.org/10.1016/j.cor.2005.03.002

Mohammed F, Selim SZ, Hassan A, Syed MN (2017) Multi-period planning of closed-loop supply chain with carbon policies under uncertainty. Transp Res Part D Transp Environ 51:146–172. https://doi.org/10.1016/j.trd.2016.10.033

Murphy PR, Poist RF (2003) Green perspectives and practices: a “comparative logistics” study. Supply Chain Manag Int J 8:122–131. https://doi.org/10.1108/13598540310468724

Noori-Darvish S, Mahdavi I, Mahdavi-Amiri N (2012) A bi-objective possibilistic programming model for open shop scheduling problems with sequence-dependent setup times, fuzzy processing times, and fuzzy due dates. Appl Soft Comput 12:1399–1416. https://doi.org/10.1016/j.asoc.2011.11.019

Özceylan E, Paksoy T, Bektaş T (2014) Modeling and optimizing the integrated problem of closed-loop supply chain network design and disassembly line balancing. Transp Res Part E Logist Transp Rev 61:142–164. https://doi.org/10.1016/j.tre.2013.11.001

Pazhani S, Ramkumar N, Narendran TT, Ganesh K (2013) A bi-objective network design model for multi-period, multi-product closed-loop supply chain. J Ind Prod Eng 30:264–280. https://doi.org/10.1080/21681015.2013.830648

Pedram A, Yusoff NB, Udoncy OE, Mahat AB, Pedram P, Babalola A (2017) Integrated forward and reverse supply chain: a tire case study. Waste Manag 60:460–470. https://doi.org/10.1016/j.wasman.2016.06.029

Pishvaee MS, Razmi J (2012) Environmental supply chain network design using multi-objective fuzzy mathematical programming. Appl Math Model 36:3433–3446. https://doi.org/10.1016/j.apm.2011.10.007

Pishvaee MS, Farahani RZ, Dullaert W (2010) A memetic algorithm for bi-objective integrated forward/reverse logistics network design. Comput Oper Res 37:1100–1112. https://doi.org/10.1016/j.cor.2009.09.018

Ramezani M, Bashiri M, Tavakkoli-Moghaddam R (2013) A new multi-objective stochastic model for a forward/reverse logistic network design with responsiveness and quality level. Appl Math Model 37:328–344. https://doi.org/10.1016/j.apm.2012.02.032

Richey GR, Genchev SE, Daugherty PJ (2005) The role of resource commitment and innovation in reverse logistics performance. Int J Phys Distrib Logist Manag 35:233–257. https://doi.org/10.1108/09600030510599913

Roghanian E, Pazhoheshfar P (2014) An optimization model for reverse logistics network under stochastic environment by using genetic algorithm. J Manuf Syst 33:348–356. https://doi.org/10.1016/j.jmsy.2014.02.007

Schaffer JD (1985) Multiple objective optimization with vector evaluated genetic algorithms. Paper presented at the Proceedings of the 1st international conference on genetic algorithms

Schultmann F, Zumkeller M, Rentz O (2006) Modeling reverse logistic tasks within closed-loop supply chains: an example from the automotive industry. Eur J Oper Res 171:1033–1050. https://doi.org/10.1016/j.ejor.2005.01.016

Soleimani H, Kannan G (2015) A hybrid particle swarm optimization and genetic algorithm for closed-loop supply chain network design in large-scale networks. Appl Math Model 39:3990–4012. https://doi.org/10.1016/j.apm.2014.12.016

Soleimani H, Seyyed-Esfahani M, Shirazi MA (2013) Designing and planning a multi-echelon multi-period multi-product closed-loop supply chain utilizing genetic algorithm. Int J Adv Manuf Technol 68:917–931. https://doi.org/10.1007/s00170-013-4953-6

Soleimani H, Govindan K, Saghafi H, Jafari H (2017) Fuzzy multi-objective sustainable and green closed-loop supply chain network design. Comput Ind Eng 109:191–203. https://doi.org/10.1016/j.cie.2017.04.038

Srinivas N, Deb K (1994) Muiltiobjective optimization using nondominated sorting in genetic algorithms. Evol Comput 2:221–248

Srivastava SK (2007) Green supply-chain management: a state-of-the-art literature review. Int J Manag Rev 9:53–80

Taguchi G (1986) Introduction to quality engineering: designing quality into products and processes. Asian Productivity Organization

Tarokh MJ, Naseri A (2012) Genetic algorithm and hybrid method to minimize total distribution cost in multi-level supply chain. J Ind Eng 46:15–26

Tiwari A, Chang P-C, Tiwari MK, Kandhway R (2016) A hybrid territory defined evolutionary algorithm approach for closed loop green supply chain network design. Comput Ind Eng 99:432–447. https://doi.org/10.1016/j.cie.2016.05.018

Üster H, Easwaran G, Akçali E, Çetinkaya S (2007) Benders decomposition with alternative multiple cuts for a multi-product closed-loop supply chain network design model. Naval Res Logist 54:890–907

Wang F, Lai X, Shi N (2011) A multi-objective optimization for green supply chain network design. Decis Support Syst 51:262–269. https://doi.org/10.1016/j.dss.2010.11.020

Yeh W-C, Chuang M-C (2011) Using multi-objective genetic algorithm for partner selection in green supply chain problems. Expert Syst Appl 38:4244–4253. https://doi.org/10.1016/j.eswa.2010.09.091

Zitzler E (1999) Evolutionary algorithm for multi-objective optimization: methods and applications. Computer Engineering and Networks Laboratory

Zohal M, Soleimani H (2016) Developing an ant colony approach for green closed-loop supply chain network design: a case study in gold industry. J Clean Prod 133:314–337. https://doi.org/10.1016/j.jclepro.2016.05.091

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Porkar, S., Mahdavi, I., Maleki Vishkaei, B. et al. Green supply chain flow analysis with multi-attribute demand in a multi-period product development environment. Oper Res Int J 20, 1405–1435 (2020). https://doi.org/10.1007/s12351-018-0382-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12351-018-0382-5