Abstract

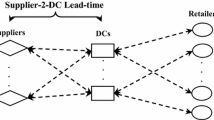

In the supply chain design problems, optimization is usually done without any attention to performance and efficiency of each part of chain. On the other hand, in Assembly Line Balancing (ALB) problems, the objective of the problems is to optimize with regard to the situation of assemblers, while in this set of problems, concentration on some factors such as how to provide raw materials and also sending final products to customers are very important. Since optimal decisions in each problem will affect the other decisions, it is required to study these two matters at the same time; otherwise, the validity of the results will be reduced. In this paper, the problem of integration of multi-product Supply Chain Network designing and ALB are addressed. A Mixed Integer Nonlinear Programming model is proposed to formulate the studied problem. The model is solved by using GAMS in the form of a numerical example given in small size. Finally, Imperialist Competitive Algorithm (ICA) and Genetic Algorithm (GA) as two well-known meta-heuristic algorithms are applied to solve the model with larger dimensions. The computational results show efficiency of the ICA compared with GA. Moreover, after decomposing the integrated mode into two sub problems (ALB problem and Supply Chain Network Design problem), it is shown that optimum cost value of integrated mode is better than total cost functions of two sub-problems separately.

Similar content being viewed by others

References

Alptekinoğlu A, Tang CS (2005) A model for analyzing multi-channel distribution systems. Eur J Oper Res 163(3):802–824

Altiparmak F, Gen M, Lin L, Paksoy T (2006) A genetic algorithm approach for multi-objective optimization of supply chain networks. Comput Ind Eng 51:196–215

Altiparmak F, Gen M, Lin L, Karaoglan I (2009) A steady-state genetic algorithm for multi-product supply chain network design. Comput Ind Eng 56(2):521–537

Andrésa C, Mirallesa C, Pastor R (2008) Balancing and scheduling tasks in assembly lines with sequence-dependent setup times. Eur J Oper Res 187:1212–1223

Arani HV, Torabi S (2018) Integrated material-financial supply chain master planning under mixed uncertainty. Inf Sci 423:96–114

Azad N, Davoudpour H (2013) Designing a stochastic distribution network model under risk. Int J Adv Manuf Technol 64(1–4):23–40

Azad N, Saharidis GKD, Davoudpour H, Malekly H, Yektamaram SA (2013) Strategies for protecting supply chain networks against facility and transportation disruptions: an improved Benders decomposition approach. Ann Oper Res 210(1):125–163

Azad N, Davoudpour H, Saharidis GKD, Shiripour M (2014) A new model to mitigating random disruption risks of facility and transportation in supply chain network design. Int J Adv Manuf Technol 70(9–12):1757–1774

Azaron A, Brown K, Tarim S, Modarres M (2008) A multi-objective stochastic programming approach for supply chain design considering risk. Int J Prod Econ 116:129–138

Bagher M, Zandieh M, Farsijani H (2011) Balancing of stochastic U-type assembly lines: an imperialist competitive algorithm. Int J Adv Manuf Technol 54(1–4):271–285

Balaman ŞY, Matopoulos A, Wright DG, Scott J (2018) Integrated optimization of sustainable supply chains and transportation networks for multi technology bio-based production: a decision support system based on fuzzy ε-constraint method. J Clean Prod 172:2594–2617

Beamon BM (1998a) Supply chain design and analysis: models and methods. Int J Prod Econ 55:281–294

Beamon BM (1998b) Supply chain design and analysis: models and methods. Int J Prod Econ 55(3):281–294

Chan FT, Chung S, Wadhwa S (2005) A hybrid genetic algorithm for production and distribution. Omega 33(4):345–355

Chatzikontidou A, Longinidis P, Tsiakis P, Georgiadis MC (2017) Flexible supply chain network design under uncertainty. Chem Eng Res Des 128:290–305

Che Z-G, Che Z, Hsu T (2009) Cooperator selection and industry assignment in supply chain network with line balancing technology. Expert Syst App 36:10381–10387

Chen C-L, Lee W-C (2004) Multi-objective optimization of multi-echelon supply chain networks with uncertain product demands and prices. Comput Chem Eng 28:1131–1144

Dasci A, Verter V (2001) A continuous model for production–distribution system design. Eur J Oper Res 129(2):287–298

Diabat A, Richard J-PP (2015) An integrated supply chain problem: a nested lagrangian relaxation approach. Ann Oper Res 229(1):303–323

Eskigun E, Uzsoy R, Preckel PV, Beaujon G, Krishnan S, Tew JD (2005) Outbound supply chain network design with mode selection, lead times and capacitated vehicle distribution centers. Eur J Oper Res 165(1):182–206

Farahani M, Shavandi H, Rahmani D (2017) A location-inventory model considering a strategy to mitigate disruption risk in supply chain by substitutable products. Comput Ind Eng 108:213–224

Govindan K, Fattahi M, Keyvanshokooh E (2017) Supply chain network design under uncertainty: a comprehensive review and future research directions. Eur J Oper Res 263(1):108–141

Grossmann IE, Kravanja Z (1995) Mixed-integer nonlinear programming techniques for process systems engineering. Comput Chem Eng 19:189–204

Guillén-Gosálbez G, Grossmann IE (2008) Optimal design and planning of sustainable chemical supply chains under uncertainty. AIChE J 55(1):99–121

Gumus AT, Guneri AF, Keles S (2009) Supply chain network design using an integrated neuro-fuzzy and MILP approach: a comparative design study. Expert Syst Appl 36:12570–12577

Haddadsisakht A, Ryan SM (2018) Closed-loop supply chain network design with multiple transportation modes under stochastic demand and uncertain carbon tax. Int J Prod Econ 195:118–131

Hall NG, Potts CN (2003) Supply chain scheduling: batching and delivery. Oper Res 51:566–584

Hwang H-S (2002) Design of supply-chain logistics system considering service level. Comput Ind Eng 43(1–2):283–297

Jayaraman V, Pirkulb H (2001) Planning and coordination of production and distribution facilities for multiple commodities. Eur J Oper Res 133(2):394–408

Koç Ç (2016) An evolutionary algorithm for supply chain network design with assembly line balancing. Neural Comput Appl 28(11):1–13

Korpela J, Lehmusvaara A (1999) A customer oriented approach to warehouse network evaluation and design. Int J Prod Econ 59(1–3):135–146

Li Q, Savachkin A (2016) Reliable distribution networks design with nonlinear fortification function. Int J Syst Sci 47(4):805–813

Li Q, Zeng B, Savachkin A (2013) Reliable facility location design under disruptions. Comput Oper Res 40(4):901–909

Lia M, Tang Q, Zheng Q, Xia X, Floudas C (2017) Rules-based heuristic approach for the U-shaped assembly line balancing problem. Appl Math Model 48:423–439

Marufuzzaman M, Eksioglu SD, Li X, Wang J (2014) Analyzing the impact of intermodal-related risk to the design and management of biofuel supply chain. Transp Res Part E: Logist Transp Rev 69:122–145

Mawandiya BK, JhaJitesh JK, Thakkar J (2018) Optimal production-inventory policy for closed-loop supply chain with remanufacturing under random demand and return. Oper Res. https://doi.org/10.1007/s12351-018-0398-x

Melachrinoudis E, Messac A, Min H (2005) Consolidating a warehouse network: a physical programming approach. Int J Prod Econ 97(1):1–17

Miranda PA, Garrido RA (2004) Incorporating inventory control decisions into a strategic distribution network design model with stochastic demand. Transp Res Part E Logist Transp Rev 40(3):183–207

Mohammadi M, Tavakkoli-Moghaddam R, Rostami H (2011) A multi-objective imperialist competitive algorithm for a capacitated hub covering location problem. Int J Ind Eng Comput 2(3):671–688

Mokashi S, Kokossis A (2003) Application of dispersion algorithms to supply chain optimisation. Comput Chem Eng 27(7):927–949

Moon C, Lee YH, Jeong CS, Yun Y (2008) Integrated process planning and scheduling in a supply chain. Comput Ind Eng 54:1048–1061

Moreira MCO, Pastor R, Costac AM, Miralles C (2017) The multi-objective assembly line worker integration and balancing problem of type-2. Comput Oper Res 82:114–125

Nourmohammadi A, Zandiehb M, Tavakkoli-Moghaddam R (2013a) An imperialist competitive algorithm for multi-objective U-type assembly line design. J Comput Sci 4(5):393–400

Nourmohammadi A, Zandiehb M, Tavakkoli-Moghaddam R (2013b) An imperialist competitive algorithm for multi-objective U-type assembly line design. J Comput Sci 4:393–400

Nozick L (2001) The fixed charge facility location problem with coverage restrictions. Transp Res Part E Logist Transp Rev 37(4):281–296

Ozceylan E, Paksoy T (2014) Fuzzy mathematical programming approaches for reverse supply chain optimization with disassembly line balancing problem. J Intell Fuzzy Syst 26(4):1969–1985

Özceylan E, Paksoy T (2013) Reverse supply chain optimisation with disassembly line balancing. Int J Prod Res 51(20):5985–6001

Paksoy T, Özceylan E (2012) Supply chain optimisation with U-type assembly line balancing. Int J Prod Res 50:5085–5105

Paksoy T, Özceylan E, Gökçen H (2012) Supply chain optimisation with assembly line balancing. Int J Prod Res 50(11):3115–3136

Pereira J, Vilà M (2016) A new model for supply chain network design with integrated assembly line balancing decisions. Int J Prod Res 54(9):2653–2669

Petridis K (2015) Optimal design of multi-echelon supply chain networks under normally distributed demand. Ann Oper Res 227(1):63–91

Rafiei H, Safaei F, Rabbani M (2018) Integrated production-distribution planning problem in a competition-based four-echelon supply chain. Comput Ind Eng 119:85–99

Rahmani D, Mahoodian V (2018) Strategic and operational supply chain network design to reduce carbon emission considering reliability and robustness. J Clean Prod 149:607–620

Ramezani M, Bashiri M, Tavakkoli-Moghaddam R (2013) A robust design for a closed-loop supply chain network under an uncertain environment. Int J Adv Manuf Technol 66(5–8):825–843

Ramezanian R, Ezzatpanah A (2015) Modeling and solving multi-objective mixed-model assembly line balancing and worker assignment problem. Comput Ind Eng 87:74–80

Romeijn HE, Shub J, Teo C-P (2007) Designing two-echelon supply networks. Eur J Oper Res 178(2):449–462

Rostami M, Bagherpour M (2017) A lagrangian relaxation algorithm for facility location of resource-constrained decentralized multi-project scheduling problems. Oper Res. https://doi.org/10.1007/s12351-017-0358-x

Sabri EH, Beamon BM (2000) A multi-objective approach to simultaneous strategic and operational planning in supply chain design. Omega 28(5):581–598

Shiripour S, Mahdavi I, Amiri-Aref M, Mohammadnia-Otaghsaraa M, Mahdavi-Amiri N (2012) Multi-facility location problems in the presence of a probabilistic line barrier: a mixed integer quadratic programming model. Int J Prod Res 50:3988–4008

Shu J, Teo C-P, Shen Z-JM (2005) Stochastic transportation-inventory network design problem. Oper Res 53(1):48–60

Soleimani H, Govindan K, Saghafi H, Jafari H (2017) Fuzzy multi-objective sustainable and green closed-loop supply chain network design. Comput Ind Eng 109:191–203

Stindt D, Sahamie R (2014) Review of research on closed loop supply chain management in the process industry. Flex Serv Manuf J 26(1–2):268–293

Syam SS (2002) A model and methodologies for the location problem with logistical components. Comput Oper Res 29(9):1173–1193

Syarif A, Yun Y, Gen M (2002) Study on multi-stage logistic chain network: a spanning tree-based genetic algorithm approach. Comput Ind Eng 43(1–2):299–314

Tavakkoli-Moghaddam R, Gholipour-Kanani Y, Shahramifar M (2013) A multi-objective imperialist competitive algorithm for a capacitated single-allocation hub location problem. Int J Eng 26:605–620

Wang B, Guan Z, Li D, Zhang C, Chen L (2014) Two-sided assembly line balancing with operator number and task constraints: a hybrid imperialist competitive algorithm. Int J Adv Manuf Technol 74(5–8):791–805

Yolmeh A, Salehi N (2015) An outer approximation method for an integration of supply chain network designing and assembly line balancing under uncertainty. Comput Ind Eng 83:297–306

Yongheng J, Rodriguez MA, Harjunkoski I, Grossmann IE (2014) Optimal supply chain design and management over a multi-period horizon under demand uncertainty. Part II: a Lagrangean decomposition algorithm. Comput Chem Eng 62:211–224

Zarandi MHF, Sisakht AH, Davari S (2011) Design of a closed-loop supply chain (CLSC) model using an interactive fuzzy goal programming. Int J Adv Manuf Technol 56(5–8):809–821

Zokaee S, Jabbarzadeh A, Fahimnia B, Sadjadi SJ (2017) Robust supply chain network design: an optimization model with real world application. Ann Oper Res 257(1–2):15–44

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ramezanian, R., Khalesi, S. Integration of multi-product supply chain network design and assembly line balancing. Oper Res Int J 21, 453–483 (2021). https://doi.org/10.1007/s12351-019-00453-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12351-019-00453-9