Abstract

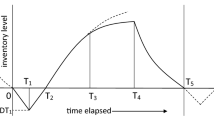

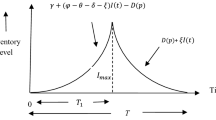

This paper explores a production inventory model in an imperfect production system under a rough interval environment. The occurrences of shortages are allowed and are fully backlogged. In this paper, two models are presented. In the first model, the demand of the product is considered as a rough interval. In the second model, both the demand and the defective rate are considered as rough intervals. In reality, these two factors cannot be assessed exactly due to a lack of available data. Moreover, there are few scenarios where the demand of the product is assessed in two-layer information. The inner layer demand is obvious, and it may extend up to the outer layer depending on the situation. Also, the same thing may happen for the defective rate of the product. In those cases, it is more reasonable to express the demand and the defective rate as rough intervals instead of fuzzy or interval numbers. Based on the expected value of rough intervals, the necessary and sufficient conditions are determined analytically to obtain the optimal inventory policies. The main advantage of this method is that the optimal profit and the optimal lot size are determined as crisp numbers rather than rough intervals. Obtaining a precise value for these two quantities is desirable for any production manager. Numerical examples for both models are provided to illustrate the solution methodology. Sensitivity analysis of the optimal solutions concerning the key parameters is conducted for identifying several managerial implications.

Similar content being viewed by others

References

Bardhan S, Pal H, Giri BC (2019) Optimal replenishment policy and preservation technology investment for a non-instantaneous deteriorating item with stock-dependent demand. Oper Res Int J 19(2):347–368

Bhunia AK, Shaikh AA, Cárdenas-Barrón LE (2017) A partially integrated production-inventory model with intervalvalued inventory costs, variable demand and flexible reliability. Appl Soft Comp 55:491–502

Chang HC (2004) An application of fuzzy sets theory to the EOQ model with imperfect quality items. Comput Oper Res 31(12):2079–2092

Cheikhrouhou N, Sarkar B, Ganguly B, Malik AI, Batista R, Lee YH (2018) Optimization of sample size and order size in an inventory model with quality inspection and return of defective items. Annals Oper Res 271(2):445–467

Datta TK (2017) Inventory system with defective products and investment opportunity for reducing defective proportion. Oper Res Int J 17(1):297–312

Datta TK, Pal AK (1988) Order-level inventory system with power demand pattern for items with variable rate of deterioration. Indian J Pure Appl Math 19(1):1043–1053

Garai T, Chakraborty D, Roy TK (2019) A fuzzy rough multi-objective multi-item inventory model with both stock-dependent demand and holding cost rate. Granul Comput 4(1):71–88

Ghosh PK, Hazari S, Dey JK, Kar S (2018) Three-layer supply chain production/by-production inventory model under fuzzy rough environment. J Adv Manuf Syst 17(1):61–88

Giri BC, Sharma S (2016) Optimal ordering policy for an inventory system with linearly increasing demand and allowable shortages under two levels trade credit financing. Oper Res Int J 16(1):25–50

Hamzehea A, Yaghoobia MA, Mashineh M (2004) Linear programming with rough interval coefficients. J Intel Fuzzy syst 26:1179–1189

Jaber MY, Goyal SK, Imran M (2008) Economic production quantity model for items with imperfect quality subject to learning effects. Int J Prod Econ 115:143–150

Jana DK, Maity K, Roy TK (2013) Multi-item production inventory model with fuzzy rough coefficients via geometric programming approach. OPSEARCH 50(4):475–490

Liu B (2002) Theory and Practice of Uncertain Programming. Physica-Verlag, Heidelberg

Mahapatra NK, Bera UK, Maiti M (2012) A Production inventory model with shortages, fuzzy preparation time and variable production and demand. Am J Oper Res 2:183–192

Mahata GC (2013) Application of fuzzy sets theory in an EOQ model for items with imperfect quality and shortage backordering. Int J Serv Oper Manag 14(4):466–490

Malik AI, Kim BS (2020) A multi-constrained supply chain model with optimal production rate in relation to quality of products under stochastic fuzzy demand. Comput Ind Eng. https://doi.org/10.1016/j.cie.2020.106814

Malik AI, Kim BS (2020) A constrained production system involving production flexibility and carbon emissions. Mathematics 8(2):275. https://doi.org/10.3390/math8020275

Malik AI, Sarkar B (2018) Optimizing a multi-product continuous-review inventory model with uncertain demand, quality improvement, setup cost reduction, and variation control in lead time. IEEE Access 6:36176–36187

Malik AI, Sarkar B (2019) Coordinating supply-chain management under stochastic fuzzy environment and lead-time reduction. Mathematics 7(5):480. https://doi.org/10.3390/math7050480

Mandal BN, Phaujdar S (1989) An inventory model for deteriorating items and stock-dependent consumption rate. J Oper Res Soc 40(5):483–488

Mondal M, Maity AK, Maiti MK, Maiti M (2013) A production-repairing inventory model with fuzzy rough coefficients under inflation and time value of money. Appl Math Model 37:3200–3215

Nagare M, Dutta P, Suryawanshi P (2020) Optimal procurement and discount pricing for single period non-instantaneous deteriorating products with promotional efforts. Oper Res Int J 20(1):89–117

Palanivel M, Uthayakumar R (2014) A production-inventory model with variable production cost and probabilistic deterioration. Asia Pacific J Math 1(2):197–212

Patro R, Nayak MM, Acharya M (2019) An EOQ model for fuzzy defective rate with allowable proportionate discount. OPSEARCH 56(1):191–215

Pawlak Z (1982) Rough Stes. Int J Parallel Progr 11(5):341–356

Porteus EL (1986) Optimal lot sizing, process quality improvement and setup cost reduction. Oper Res 34(1):137–144

Rebolledo M (2006) Rough intervals-enhancing intervals for qualitative modeling of technical systems. Artif Intel 170:667–685

Rosenblatt MJ, Lee HL (1986) Economic production cycles with imperfect production process. IIE Trans 18(1):48–55

Ruidas S, Seikh MR, Nayak PK (2020) An EPQ model with stock and selling price dependent demand and variable production rate in interval environment. Int J Syst Assur Eng Manag 11(2):385–399

Ruidas S, Seikh MR, Nayak PK, Pal M (2018) Interval valued EOQ model with two types of defective items. J Stat Manag Syst 21(6):1059–1082

Ruidas S, Seikh MR, Nayak PK, Sarkar B (2019) A single period production inventory model in interval environment with price revision. Int J Appl Comput Mat. https://doi.org/10.1007/s40819-018-0591-x

Salameh M, Jaber M (2000) Economic production quantity model for items with imperfect quality. Int J Prod Econ 64(1–3):59–64

Sarkar B, Dey BK, Pareek S, Sarkar M (2020) A single-stage cleaner production system with random defective rate and remanufacturing. Comput Ind Eng. https://doi.org/10.1016/j.cie.2020.106861

Sarkar B, Moon I (2011) An EPQ model with inflation in an imperfect production system. Appl Math Comput 217:6159–6167

Shah NH, Patel DG, Shah DB (2018) EPQ model for returned/reworked inventories during imperfect production process under price-sensitive stock-dependent demand. Oper Res Int J 18(2):343–359

Shaikh AA, LE C-B, Tiwari S (2019) A two-warehouse inventory model for non-instantaneous deteriorating items with interval-valued inventory costs and stock-dependent demand under inflationary conditions. Neural Comput Appl 31(6):1931–1948

Taleizadeh AA, Wee HM, Jolai F (2013) Revisiting a fuzzy rough economic order quantity model for deteriorating items considering quantity discount and prepayment. Math Comput Model 57(5–6):1466–1479

Xu J, Zhao L (2008) A class of fuzzy rough expected value multi-objective decision making model and its application to inventory problems. Comput Math Appl 56:2107–2119

Xu J, Tao Z (2012) Rough multiple objective decision making. CRC Press, pp22-28

Acknowledgements

The authors would like to thank the learned anonymous reviewers and the editor for their valuable suggestions, constructive comments, and excellent observations which have substantially helped to improve the quality of the paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ruidas, S., Seikh, M.R. & Nayak, P.K. A production-repairing inventory model considering demand and the proportion of defective items as rough intervals. Oper Res Int J 22, 2803–2829 (2022). https://doi.org/10.1007/s12351-021-00634-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12351-021-00634-5