Abstract

Semiconducting silicon wafers were subjected to centrifugal wet cleaning to remove micro-contaminants. The circular wafers were rotated while a cleaning liquid was supplied to the wafer surface. During such a cleaning process, the centrifugal force atomizes the liquid film at the wafer edges, producing drops. These drops travel in the confined chamber, collide with the chamber walls, and form splashed droplets. Thereafter, the splashed droplets return to the wafer, thereby significantly increasing the risk of re-contamination. Given this wafer wet cleaning scenario, we experimentally investigated the trajectories of splashed droplets. We introduced metal mesh filtration and air-blowing techniques to minimize wafer re-contamination by the splashed droplets. The metal mesh decreased the speed of the drops, thus minimizing the intensity of splashing. The droplets were also air-blown with a supersonic stream to deflect the droplets from their trajectories and thus prevent them from reaching the wafer. The optimal air-blowing condition was determined through parametric studies. The metal mesh was electroplated with copper, producing textured surfaces on the mesh wires. In addition, the metal fiber mats were laminated on the metal mesh and the effects of these on splashing were studied. Further, photographs of droplets spreading and splashing over these metal meshes were captured to elucidate their detailed dynamics. Time-series snapshots of drops penetrating the metal meshes were also captured.

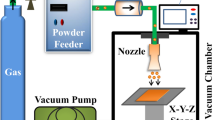

Graphic abstract

Similar content being viewed by others

Abbreviations

- d 1 :

-

Distance from impact location to sensitive paper (horizontal) (mm)

- d 2 :

-

Distance from disk edge to mesh (horizontal) (mm)

- D :

-

The spreading diameter (mm)

- DM:

-

Double layer meshes

- D drop :

-

Diameter of drop (mm)

- D 0 :

-

Initial diameter of drop (mm)

- D p :

-

Mesh pore size (mm)

- D w :

-

Mesh wire diameter (mm)

- EP:

-

Electroplating

- h 1 :

-

Gap between mesh and acrylic wall (vertical) (mm)

- h 2 :

-

Gap between sensitive paper bottom edge and disk top (vertical) (mm)

- h 3 :

-

Distance between liquid nozzle exit to disk top (vertical) (mm)

- H 1 :

-

Distance between liquid nozzle exit to mesh (vertical) (cm)

- H 2 :

-

Distance between supersonic air nozzle to disk top (vertical) (cm)

- N :

-

The number of multiple drops

- N m :

-

The number of meshes

- Re:

-

Reynolds number

- SM:

-

Single layer mesh

- t :

-

Interval time (s)

- u i :

-

Drop impact speed (m/s)

- W :

-

Drop impact speed (%)

- We:

-

Weber number

- γ :

-

Geometric ratio, γ = 1 + Dw/Dp

- ρ :

-

Liquid density (kg/m3)

- μ :

-

Liquid dynamic viscosity (N s/m2)

- σ :

-

Liquid surface tension (N/m)

References

An S, Lee C, Liou M, Jo HS, Park J-J, Yarin AL et al (2014) Supersonically blown ultrathin thorny devil nanofibers for efficient air cooling. ACS Appl Mater Interfaces 6(16):13657–13666

An S, Jo HS, Kim DY, Lee HJ, Ju BK, Al-Deyab SS et al (2016) Self-junctioned copper nanofiber transparent flexible conducting film via electrospinning and electroplating. Adv Mater 28(33):7149–7154

Boscariol C, Chandra S, Sarker D, Crua C, Marengo M (2018) Drop impact onto attached metallic meshes: liquid penetration and spreading. Exp Fluids 59(12):189

Chandrasekhar S (1981) Hydrodynamic and hydromagnetic stability. Dover Publications, Mineola

Drazin PG, Reid WH (2004) Hydrodynamic stability. Cambridge University Press, Cambridge

Hattori T, Osaka T, Okamoto A, Saga K, Kuniyasu H (1998) Contamination removal by single-wafer spin cleaning with repetitive use of ozonized water and dilute HF. J Electrochem Soc 145(9):3278–3284

Kern W (1990) The evolution of silicon wafer cleaning technology. J Electrochem Soc 137(6):1887–1892

Kim M-w, Yoon H, Ohm TY, Jo HS, An S, Choi SK et al (2017) Nanotextured cupric oxide nanofibers coated with atomic layer deposited ZnO-TiO2 as highly efficient photocathodes. Appl Catal B Environ 201:479–485

Kim T-G, Lee J-G, Park C-W, Jo H-S, Kim M-W, van Hest MF et al (2018) Effect of supersonic spraying impact velocity on opto-electric properties of transparent conducting flexible films consisting of silver nanowire, ITO, and polyimide multilayers. J Alloys Compd 739:653–659

Lee JG, Kim D-Y, Lee J-H, Kim M-w, An S, Jo HS et al (2016) Scalable binder-free supersonic cold spraying of nanotextured cupric oxide (CuO) films as efficient photocathodes. ACS Appl Mater Interfaces 8(24):15406–15414

Lee JG, Kim DY, Lee JH, Sinha-Ray S, Yarin AL, Swihart MT et al (2017) Production of flexible transparent conducting films of self-fused nanowires via one-step supersonic spraying. Adv Funct Mater 27(1):1602548

Lefebvre A (1988) Atomization and sprays. Begell House, Danbury

Lembach AN, Tan H-B, Roisman IV, Gambaryan-Roisman T, Zhang Y, Tropea C et al (2010) Drop impact, spreading, splashing, and penetration into electrospun nanofiber mats. Langmuir 26(12):9516–9523

Rayleigh L (1878) On the instability of jets. Proc Lond Math Soc s1-10(1):4–13

Ruzyllo J, Hattori T (2014) Preface to the focus issue on semiconductor surface cleaning and conditioning. ECS J Solid State Sci Technol 3(1):Y1

Ruzyllo J, Hattori T, Novak RE, Mertens P, Besson P (2007) Evolution of silicon cleaning technology over the last twenty years. ECS Trans 11(2):3–7

Ryoo K (2005a) Characteristics of electrolyzed anode water as a display cleaning medium. Met Mater Int 11(4):295–299

Ryoo K (2005b) Metal oxide particle removal using electrolyzed anode water. J Electrochem Soc 152(11):G885–G888

Ryu S, Sen P, Nam Y, Lee C (2017) Water penetration through a superhydrophobic mesh during a drop impact. Phys Rev Lett 118(1):014501

Sahu RP, Sinha-Ray S, Yarin A, Pourdeyhimi B (2012) Drop impacts on electrospun nanofiber membranes. Soft Matter 8(14):3957–3970

Sahu R, Sinha-Ray S, Yarin A, Pourdeyhimi B (2013) Blowing drops off a filament. Soft Matter 9(26):6053–6071

Sahu R, Sett S, Yarin A, Pourdeyhimi B (2015) Impact of aqueous suspension drops onto non-wettable porous membranes: hydrodynamic focusing and penetration of nanoparticles. Colloids Surf A Physicochem Eng Asp 467:31–45

Sato N, Yamazaki O, Shimogaki Y (2012) Impacts of chemical supply flow on particle removability in wet clean bath. J Electrochem Soc 159(4):H367–H372

Shapiro AH (1953) The dynamics and thermodynamics of compressible fluid flow, vol 1. Ronald Press, New York

Xu J, Xie J, He X, Cheng Y, Liu Q (2017) Water drop impacts on a single-layer of mesh screen membrane: effect of water hammer pressure and advancing contact angles. Exp Therm Fluid Sci 82:83–93

Yoon H, Kim M-w, Kim H, Kim D-Y, An S, Lee J-G et al (2016) Efficient heat removal via thorny devil nanofiber, silver nanowire, and graphene nanotextured surfaces. Int J Heat Mass Transf 101:198–204

Zhang G, Quetzeri-Santiago MA, Stone CA, Botto L, Castrejón-Pita JR (2018) Droplet impact dynamics on textiles. Soft Matter 14(40):8182–8190

Acknowledgements

This research was supported by the Technology Development Program to Solve Climate Changes of the National Research Foundation (NRF) funded by the Ministry of Science, ICT and Future Planning (NRF-2016M1A2A2936760), NRF-2017R1A2B4005639, and NRF-2013R1A5A1073861. This research is also funded by King Saud University, Riyadh, Saudi Arabia, Researchers Supporting Project (RSP-2019/30).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary file1 (WMV 65029 kb)

Rights and permissions

About this article

Cite this article

Park, CW., Kim, TG., Kim, MW. et al. Splash suppression during wafer wet cleaning through drop penetration across metal meshes and porous fiber mats. J Vis 23, 269–285 (2020). https://doi.org/10.1007/s12650-019-00620-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12650-019-00620-2