Abstract

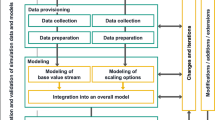

Facing the new trend of Industry 4.0, manufacturing factories are required to have a more flexible structure to finish producing customized products within the limited time and at a reasonable cost. Although virtual factory technology is believed to be helpful for plant layout design and production planning, there still lacks a general framework and algorithms of simulation-based approach to design an optimized plant layout and the production process. This paper proposes a framework of simulation-based approach and develops a procedure for the implementation of the proposed framework. The paper also integrates mathematical algorithms and heuristic methods when applying simulation to balance the operation performance and the planning cost. An illustrative case demonstrates that the proposed approach can achieve the goal of better plant layout design and production planning.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

Alahmari A, Abidi MH, Ahmad A, Darmoul S (2016) Development of a virtual manufacturing assembly simulation system. Adv Mech Eng 8(3):1–13

Automod (2017) http://www.appliedmaterials.com. Accessed 17 Dec 2017

CATIA V6 (2017) https://www.3ds.com/products-services/catia/products/v6/. Accessed 07 Oct 2017

Dasgupta D, Michalewicz Z (2013) Evolutionary algorithms in engineering applications. Springer, Berlin

Ducloux R (2014) Improvement of part or tooling life prediction through simulation of whole manufacturing process. Procedia Eng 81:504–509

Grienitz V, Hausicke M, Goerzel S, Dangelmaier W, Laroque C (2013) Systemic manufacturing process modelling and optimization with integrated simulation. In: A. Klass (ed) Simulation in Produktion Und Logistk 2013, pp 99–108

Groover MP (2007) Fundamentals of modern manufacturing: materials processes, and systems. Wiley, Hoboken

Kia R, Khaksarhaghani F, Javadian N, Tavakkolimoghaddam R (2014) Solving a multi-floor layout design model of a dynamic cellular manufacturing system by an efficient genetic algorithm. J Manuf Syst 33(1):218–232

Lenin N, Siva Kumar M, Islam MN, Ravindran D (2013) Multi-objective optimization in single-row layout design using a genetic algorithm. Int J Adv Manuf Technol 67(5–8):1777–1790

Li GQ, Zhao FQ, Guo C, Teng HF (2006) Parallel hybrid PSO-GA algorithm and its application to layout design. In: International conference on natural computation. Springer, Berlin, Heidelberg, 749–758

Lin MH, Fu LC (2001) A virtual factory based approach to on-line simulation and scheduling for an FMS and a case study. J Intell Manuf 12(3):269–279

Lindskog E, Vallhagen J, Berglund J, Johansson B (2016) Improving lean design of production systems by visualization support. Procedia CIRP 41:602–607

Liu XX, Liu QY, Wang W (2013) Development of virtual simulation in manufacturing industry. In: Applied mechanics and materials. Trans Tech Publ, Switzerland

Molano JIR, Lovelle JMC, Montenegro CE, Granados JJR, Crespo RG (2017) Metamodel for integration of Internet of Things, Social Networks, the Cloud and Industry 4.0. J Ambient Intell Humaniz Comput. https://doi.org/10.1007/s12652-017-0469-5

Mourtzis D, Doukas M, Bernidaki D (2014) Simulation in manufacturing: review and challenges. Procedia CIRP 25:213–229

Mujber TS, Szecsi T, Hashmi MS (2004) Virtual reality applications in manufacturing process simulation. J Mater Process Technol 155:1834–1838

Pahl G, Beitz W, Feldhusen J, Grote KH (2007) Engineering design: a systematic approach. Springer, Berlin

Plant Simulation (2017) https://www.plm.automation.siemens.com. Accessed 07 Oct 2017

Promodel (2016) Simulation Conversations with ProModel. 2016. https://blog.promodel.com. Accessed 07 Oct 2017

Promodel (2017) https://www.promodel.com/Products/ProModel. Accessed 07 Oct 2017

Rong H (2011) Design of automatic block section signalling layout of appling chaos embedded particle swarm optimization algorithm based on skew tent map. Inf Control, Autom Robot 132:785–792 (Lecture Notes in Electrical Engineering book series)

Siano P, Graditi G, Atrigna M, Piccolo A (2013) Designing and testing decision support and energy management systems for smart homes. J Ambient Intell Humaniz Comput 4(6):651–661

Suh NP (2001) Axiomatic design: advances and applications. Oxford University Press, Oxford

Tao F, Qi Q (2017a) New IT driven service-oriented smart manufacturing: framework and characteristics. IEEE Trans Syst Man Cybern Syst. https://doi.org/10.1109/TSMC.2017.2723764

Tao F, Zhang M (2017e) Digital twin shop-floor: a new shop-floor paradigm towards smart manufacturing. IEEE Access 5:20418–20427

Tao F, Zhao D, Hu Y, Zhou Z (2008) Resource service composition and its optimal-selection based on particle swarm optimization in manufacturing grid system. IEEE Trans Industr Inf 4(4):315–327

Tao F, Guo H, Zhang L, Cheng Y (2012) Modelling of combinable relationship-based composition service network and theoretical proof of its scale-free characteristics. Enterp Inf Syst 6(4):373–404

Tao F, Zuo Y, Xu LD, Zhang L (2014) IoT-based intelligent perception and access of manufacturing resource toward cloud manufacturing. IEEE Trans Industr Inf 10(2):1547–1557

Tao F, Cheng JF, Cheng Y, Gu SX, Zheng TY, Yang H (2017b) SDMSim: a manufacturing service supply–demand matching simulator under cloud environment. Robot Comput Integr Manuf 45(6):34–46

Tao F, Cheng J, Qi Q (2017c) IIHub: an industrial internet-of-things hub towards smart manufacturing based on cyber-physical system. IEEE Trans Industr Inf. https://doi.org/10.1109/TII.2017.2759178

Tao F, Cheng J, Qi Q, Zhang M, Zhang H, Sui F (2017d) Digital twin-driven product design, manufacturing and service with big data. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-017-0233-1

Terkaj W, Tolio T, Urgo M (2015) A virtual factory approach for in situ simulation to support production and maintenance planning. CIRP Ann Manuf Technol 64(1):451–454

Ullman DG (2017) The mechanical design process. McGraw-Hill, New York

Yang T, Kuo Y, Su C, Hou C (2015) Lean production system design for fishing net manufacturing using lean principles and simulation optimization. J Manuf Syst 34:66–73

Yap HJ, Taha Z, Dawal SZ, Chang S (2014) Virtual reality based support system for layout planning and programming of an industrial robotic work cell. PloS One 9(10):e109692

Yildiz AR (2013) A new hybrid artificial bee colony algorithm for robust optimal design and manufacturing. Appl Soft Comput 13(5):2906–2912

Zhang ZN, Liu G, Jiang ZC, Chen Y (2015) A cloud-based framework for lean maintenance, repair, and overhaul of complex equipment. J Manuf Sci Eng 137(4):040908

Acknowledgements

This research is partially supported by the Ministry of Industry and Information Technology of the People’s Republic of China (2016ZXFM03002), the Shanghai Academy of Space Technology-Shanghai Jiao Tong University Joint Research Center of Advanced Aerospace Technology (USCAST2016-16) and National Key Technology Support Program (2015BAF18B02). Special thanks to Mr. Weimin Ding for the case study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Z., Wang, X., Wang, X. et al. A simulation-based approach for plant layout design and production planning. J Ambient Intell Human Comput 10, 1217–1230 (2019). https://doi.org/10.1007/s12652-018-0687-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12652-018-0687-5