Abstract

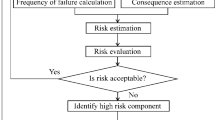

During their operational lifetime, the static process equipment (including piping, pipelines and topside static equipment) that constitute an offshore oil and gas production installation are subjected to a number of degrading mechanisms, like corrosion and erosion. These degradation mechanisms can significantly reduce the integrity of equipment thereby increasing their possibility of their failure. In order to mitigate the risk associated with the failure, the pipes/equipment are regularly inspected, monitored or tested using various techniques. These inspection–monitoring–testing activities can provide valuable data/information about the existing condition of the pipes/equipment and provide direction for future maintenance activities. Unfortunately, all these inspection–maintenance activities may result in a vast amount of, potentially imperfect, data that may be difficult to interpret. Currently, data from various stages: design, operation, inspection, monitoring and maintenance etc. are collected but often inefficiently used. The decisions regarding future inspection and maintenance programs are therefore made without taking into consideration all relevant data. Thus there is a need to develop systems that can effectively use the maximum amount of available data to aid in the decision-making process. This paper discusses a framework for an intelligent human-centric decision support system based on the concepts of data–information–knowledge hierarchy. Such a system can help inspection engineers effectively use available databases, information systems and knowledge-based systems for implementing risk-based inspection analysis of degrading structures.

Similar content being viewed by others

References

Aamodt A, Nygård M (1995) Different roles and mutual dependencies of data, information, and knowledge—an AI perspective on their integration. Data Knowl Eng 16:191–222

Ackoff Russell (1989) From data to wisdom. J Appl Syst Anal 16:3–9

American Bureau of Shipping (ABS) (2003) Guide for surveys using risk-based inspection for the offshore industry

American Petroleum Institute (2002) API 580: risk-based inspection

Bernstein JH (2009) The data–information–knowledge–wisdom hierarchy and its antithesis. In: Proceedings 2009 North American symposium on knowledge organization, vol 2, pp 68–75

Det Norske Veritas (DNV) (2004) Recommended practice DNV-RP-F101: corroded pipelines. Det Norske Veritas (DNV), Høvik

Det Norske Veritas (DNV) (2009) Recommended practices DNV-RP-G101: risk based inspection of offshore topsides static mechanical equipment. Det Norske Veritas, Høvik

IEC 300-3-9—Dependability management—application guide—risk analysis of technological systems

International Organization for Standardization (ISO) (2009) ISO 31000:2009, Risk management—principles and guidelines

Low DW (2009) Data, information, knowledge: a semiotic-system’s view for database design. In: Proceedings of the 53rd annual meeting of the ISSS, University of Queensland, Brisbane, Australia July 12th–17th, 2009

NORSOK Standard Z008 Risk based maintenance and consequence classification

Singh M, Markeset T (2009) A methodology for risk-based inspection planning of oil and gas pipes based on fuzzy logic framework. Eng Fail Anal 16:2098–2113

Singh M, Fosselie T, Wiggen F (2010) Data, information, knowledge and decision-making in condition monitoring. In: Proceedings of the 23rd international congress & exhibition on condition monitoring and diagnostic engineering management (COMADEM 2010), Nara, Japan

Singh M, Markeset T, Kumar U (2014) Some philosophical issues in modeling corrosion of oil and gas pipelines. Int J Syst Assur Eng Manag 5(1):55–74

Stenmark D (2002) Information vs. knowledge: the role of intranets in knowledge management. In: Proceedings of the 35th Hawaii international conference on system sciences

The American Society of Mechanical Engineers (1991) ASME B31G-1991: manual for determining the remaining strength of corroded pipelines

Zins C (2007) Conceptual approaches for defining data, information, and knowledge. J Am Soc Inform Sci Technol 58(4):479–493

Author information

Authors and Affiliations

Corresponding author

Additional information

A shorter version of this paper was published as Singh, M., Fosselie, T. and Wiggen, F., Data, information, knowledge and decision-making in condition monitoring, Proceedings of COMADEM 2010, The 23rd International Congress & Exhibition on Condition Monitoring and Diagnostic Engineering Management, Nara, Japan, 2010.

Rights and permissions

About this article

Cite this article

Singh, M., Hetlevik, S. Data–information–knowledge hierarchy based decision support system for risk based inspection analysis. Int J Syst Assur Eng Manag 8 (Suppl 2), 1588–1595 (2017). https://doi.org/10.1007/s13198-017-0631-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-017-0631-7