Abstract

This study aims to enhance the condition monitoring of external ball bearings using the raw data provided by Paderborn University which provided sufficient data for motor current signal MCS. Three classes of bearings have been used: healthy bearings, bearings with an inner race defect, and bearings with outer race defect. Online data at different operating conditions, bearings, and faults extent of artificial and real damages have been chosen to provide the generalization and robustness of the model. After proper preprocessing to the raw data of vibration and MCS, time, frequency, and time–frequency domain features have been extracted. Then, optimal features have been selected using genetic algorithm. Artificial neural network with optimized structure using genetic algorithm has been implemented. A comparison between the performance of vibration and motor current signal has been presented. Moreover, our results are compared to previous work by using the same raw data. Results showed the potential of motor current signal in bearing fault diagnosis with high classification accuracy. Moreover, the results showed the possibility to provide a promised diagnostic model that can diagnose bearings of real faults with different fault severities using MCS.

Similar content being viewed by others

References

Alsyouf, I.: The role of maintenance in improving companies’ productivity and profitability. Int. J. Prod. Econ. 105, 70–78 (2007)

Al-Najjar, B., Wang, W.: A conceptual model for fault detection and decision making for rolling element bearings in paper mills. J. Qual. Maint. Eng. 7(3), 192–206 (2001)

Henao, H., et al.: Trends in fault diagnosis for electrical machines: a review of diagnostic techniques. IEEE Ind. Electron. Mag. 8(2), 31–42 (2014)

Bonnett, A.H., Yung, C.: Increased efficiency versus increased reliability. IEEE Ind. Appl. Mag. 14(1), 29–36 (2008)

Wu, D., Wang, H., Liu, H., He, T., Xie, T.: Health monitoring on the spacecraft bearings in high-speed rotating systems by using the clustering fusion of normal acoustic parameters. Appl. Sci. 9(16), 3246 (2019)

Samanta, B., Al-Balushi, K.R.: Artificial neural network based fault diagnostics of rolling element bearings using time-domain features. Mech. Syst. Signal Process. 17(2), 317–328 (2003)

Kankar, P.K., Sharma, S.C., Harsha, S.P.: Fault diagnosis of ball bearings using machine learning methods. Expert Syst. Appl. 38(3), 1876–1886 (2011)

Marichal, G., Artes, M., Garcia-Prada, J.: An intelligent system for faulty-bearing detection based on vibration spectra. J. Vib. Control 17(6), 931–942 (2011)

Khadersab, A., Shivakumar, S.: Vibration analysis techniques for rotating machinery and its vibration analysis effect techniques for rotating on bearing faults machinery and its effect on bearing faults costing models for capacity optimization in industry 4. 0: trade-off between used capacity and operational efficiency. Procedia Manuf. 20, 247–252 (2018)

Nikolaou, N.G., Antoniadis, I.A.: Rolling element bearing fault diagnosis using wavelet packets. Ndt & E Int. 35, 197–205 (2002)

Soualhi, A., Hawwari, Y., Medjaher, K., Guy, C., Razik, H., Guillet, F.: PHM survey: implementation of signal processing methods for monitoring bearings and gearboxes. Int. J. Prognostics Health Manage. 9, (2018)

Jardine, A.K.S., Lin, D., Banjevic, D.: A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal. Process. 20, 1483–1510 (2006)

Liu, T.I., Singonahalli, J.H., Iyer, N.R.: Detection of roller bearing defects using expert system and fuzzy logic. Mech. Syst. Signal Process. 10, 595–614 (1996)

Alguindigue, I.E., Loskiewicz-Buczak, A., Uhrig, R.E.: Monitoring and diagnosis of rolling element bearings using artificial neural networks. IEEE Trans. Ind. Electron. 40(2), 209–217 (1993)

Jack, L.B., Nandi, A.K.: Genetic algorithms for feature selection in machine condition monitoring with vibration signals. IEE Proc. Vis. Image Signal Process. 147(3), 205–212 (2000)

Jenkins, C.D.: Bearing fault detection and wear estimation using machine learning. Los Alamos National Lab (LANL), Los Alamos (2019)

Lessmeier, C., Kimotho, J.K., Zimmer, D., Sextro, W.: Condition monitoring of bearing damage in electromechanical drive systems by using motor current signals of electric motors: a benchmark data set for data-driven classification. In: European Conference of the Prognostics and Health Management Society 2016, no. July, p. 17 (2016)

Blodt, M., Granjon, P., Raison, B., Rostaing, G.: Models for bearing damage detection in induction motors using stator current monitoring. IEEE Trans. Ind. Electron. 55(4), 1813–1822 (2008)

Zarei, J., Poshtan, J.: An advanced Park’s vectors approach for bearing fault detection. IEEE Int. Conf. Ind. Technol. Mumbai pp. 1472-1479 (2006). https://doi.org/10.1109/ICIT.2006.372562

Nectoux, P., Gouriveau, R., Medjaher, K., Ramasso, E., Chebel-Morello, B., Zerhouni, N., Varnier, C.: PRONOSTIA: an experimental platform for bearings accelerated degradation tests. IEEE Int. Conf. Prognostics Health Manag. PHM'12., Denver, Colorado, United States. pp.1–8. (hal- 00719503) (2012)

McFadden, P.D., Smith, J.D.: Model for the vibration produced by a single point defect in a rolling element bearing. J. Sound Vib. 96(1), 69–82 (1984)

Stack, J.R., Habetler, T.G., Harley, R.G.: Fault classification and fault signature production for rolling element bearings in electric machines. In: IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, SDEMPED 2003—Proceedings, vol. 40, no. 3, pp. 172–176 (2003)

McInerny, S.A., Dai, Y.: Basic vibration signal processing for bearing fault detection. IEEE Trans. Educ. 46(1), 149–156 (2003)

Tondon, N., Choudhury, A.: A review of vibration and acoustics measurement methods for the detection of defects in rolling element bearing. Tribol. Int. 32(8), 469–480 (1999)

Bartheld, R.G., Habetler, T.G., Kamran, F.: Motor bearing damage detection using stator current monitoring. IEEE Trans. Ind. Appl. 31(6), 1274–1279 (1995)

Index of /kat/BearingDataCenter: https://groups.uni-paderborn.de/kat/BearingDataCenter/ (2016). Accessed 02 March 2019

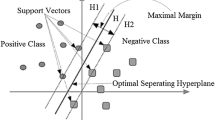

Samanta, B., Al-Balushi, K.R., Al-Araimi, S.A.: Artificial neural networks and support vector machines with genetic algorithm for bearing fault detection. Eng. Appl. Artif. Intell. 16(7–8), 657–665 (2003)

Obaid, R.R., Habetler, T.G., Stack, J.R.: Stator current analysis for bearing damage detection in induction motors. In: Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, no. August (2003)

Demuth, H.B., Beale, M.H., De Jess, O., Hagan, M.T.: Neural network design. Martin Hagan, Stillwater (2014)

Mathew, J.: The condition monitoring of rolling element bearings using vibration analysis. J. Vib. Acoust. 106, 447–453 (1984)

Prabhakar, S., Mohanty, A.R., Sekhar, A.S.: Application of discrete wavelet transform for detection of ball bearing race faults. Tribol. Int. 35(12), 793–800 (2002)

Ocak, H., Loparo, K.A., Discenzo, F.M.: Online tracking of bearing wear using wavelet packet decomposition and probabilistic modeling: a method for bearing prognostics. J. Sound Vib. 302(4–5), 951–961 (2007)

Kimotho, J.K., Sextro, W.: An approach for feature extraction and selection from non-trending data for machinery prognosis. In: Proceedings of the Second European Conference of the Prognostics and Health Management Society, pp. 1–8 (2014)

Samanta, B.: Gear fault detection using artificial neural networks and support vector machines with genetic algorithms. Mech. Syst. Signal Process. 18(3), 625–644 (2004)

Genetic Algorithm Options—MATLAB & Simulink: https://www.mathworks.com/help/gads/genetic-algorithm-options.html (2019). Accessed 2 March 2019

Umbarkar, A., Sheth, P.: Crossover operators in genetic algorithms: a review. ICTACT J Soft Comput (2015). https://doi.org/10.21917/ijsc.2015.0150

Deep, K., Pratap, K., Kansal, M.L., Mohan, C.: A real coded genetic algorithm for solving integer and mixed integer optimization problems. Appl. Math. Comput. 212(2), 505–518 (2009)

Michalewicz, Z.: Genetic Algorithms + Data Structures = Evolution Programs, 3rd edn. Springer, Berlin (1996)

Wang, B.: Data fused motor fault identification based on adversarial auto-encoder. In: 2019 IEEE 10th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), pp. 299–305 (2019)

Acknowledgements

The authors would like to acknowledge the Mechatronics and Dynamics research group at the University of Paderborn for offering an internship opportunity to work in their labs and projects through NRW scholarship program (https://mb.uni-paderborn.de/en/ldm/). Special thanks to Dr. James Kuria (jkimotho@campus.upb.de) for his valuable guidance, thoughts, and discussion which helped to present this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sawaqed, L.S., Alrayes, A.M. Bearing fault diagnostic using machine learning algorithms. Prog Artif Intell 9, 341–350 (2020). https://doi.org/10.1007/s13748-020-00217-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13748-020-00217-z