Abstract

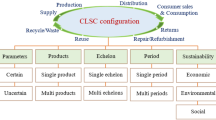

The supply chain network design problem addresses various factors that maximize customers’ demand and minimizes the sum of strategic, tactical, and operational costs. Companies with common activities in their supply chains have started to cooperate with each other to achieve better service levels. Based on this initiative, a multi-level mixed-integer linear programming model is developed that includes two allied supply chains with different decision makers (DM) at two different decision-making levels. The primary aim of this study is to design an allied closed-loop supply chain (CLSC) network that uses some of the same facilities. The secondary aim of this study is to examine this allied CLSC model simultaneously and analyse the impact of the DMs’ objectives based on satisfaction degrees. Various interactive fuzzy programming (IFP) approaches were utilized to examine the presented multi-level CLSC model. A novel IFP approach which is based on the fuzzy analytic hierarchy process (AHP) is proposed. The effectiveness of the proposed IFP approach on the CLSC model is investigated with hypothetical data. The computational results show that the proposed approach obtains higher satisfaction degrees for upper-level DMs than the other approaches.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Abbreviations

- SCND:

-

Supply chain network design

- DM:

-

Decision maker

- IFP:

-

Interactive fuzzy programming

- AHP:

-

Analytic hierarchy process

- SC:

-

Supply chain

- CLSC:

-

Closed-loop supply chain

- SO:

-

Selim and Ozkarahan [11] approach

- TH:

-

Torabi and Hassini [12] approach

- ZIM:

-

Zimmermann [15] approach

- i :

-

Set of common suppliers i = {1, 2…I}

- r :

-

Set of suppliers for SC1 r = {1, 2…R}

- s :

-

Set of suppliers for SC2 s = {1, 2…S}

- m :

-

Set of plants for SC1 m = {1, 2…M}

- n :

-

Set of plants for SC2 n = {1, 2…N}

- u :

-

Set of customers for SC1 u = {1, 2…U}

- v :

-

Set of customers for SC2 v = {1, 2…V}

- j :

-

Set of common collection centres j = {1, 2…J}

- c :

-

Set of parts c = {1, 2…C}

- t :

-

Set of periods t = {1, 2…T}

- d rm :

-

Distance between supplier r and plant m for SC1 (km)

- d sn :

-

Distance between supplier s and plant n for SC2 (km)

- d im :

-

Distance between common supplier i and plant m for SC1 (km)

- d in :

-

Distance between common supplier i and plant n for SC2 (km)

- d mu :

-

Distance between plant m and customer u for SC1 (km)

- d nv :

-

Distance between plant n and customer v for SC2 (km)

- d uj :

-

Distance between customer u and common collection centre j for SC1 (km)

- d vj :

-

Distance between customer v and common collection centre j for SC2 (km)

- d jm :

-

Distance between common collection centre j and plant m for SC1 (km)

- d jn :

-

Distance between common collection centre j and plant n for SC2 (km)

- \(a_{rct}^{\text{I}}\) :

-

Capacity of supplier r for part c in period t for SC1 (ton)

- \(a_{sct}^{\text{II}}\) :

-

Capacity of supplier s for part c in period t for SC2 (ton)

- a ict :

-

Capacity of common supplier i for part c in period t (ton)

- \(b_{mct}^{\text{I}}\) :

-

Capacity of plant m for part c in period t for SC1 (ton)

- \(b_{nct}^{\text{II}}\) :

-

Capacity of plant n for part c in period t for SC2 (ton)

- ca jt :

-

Capacity of common collection centre j in period t (ton)

- \({\text{de}}_{ut}^{\text{I}}\) :

-

Demand of customer u in period t for SC1 (ton)

- \({\text{de}}_{vt}^{\text{II}}\) :

-

Demand of customer v in period t for SC2 (ton)

- \(\alpha_{mt}^{\text{I}}\) :

-

The fixed opening cost for plant m in period t for SC1 ($)

- α II nt :

-

The fixed opening cost for plant n in period t for SC2 ($)

- α jt :

-

The fixed opening cost for common collection centre j in period t ($)

- p rc :

-

Unit cost of purchasing of supplier r for part c for SC1 ($/ton)

- p sc :

-

Unit cost of purchasing of supplier s for part c for SC2 ($/ton)

- p ic :

-

Unit cost of purchasing cost/sale price of common supplier i for part c ($/ton)

- e jc :

-

Unit cost of purchasing cost/sale price of common collection centre j for part c ($/ton)

- \({\text{hcp}}_{mct}^{\text{I}}\) :

-

Unit holding cost of part c at plant m in period t for SC1 ($/ton)

- \({\text{hcp}}_{nct}^{\text{II}}\) :

-

Unit holding cost of part c at plant n in period t for SC2 ($/ton)

- r c :

-

The weight ratio of one part c in end product

- η 1 :

-

Percentage of collected amount which is re-sent to plants for SC1 (%)

- η 2 :

-

Percentage of collected amount which is re-sent to plants for SC2 (%)

- λ 1 :

-

Percentage of kept amount in inventory for SC1 (%)

- λ 2 :

-

Percentage of kept amount in inventory for SC2 (%)

- utc:

-

Unit cost of shipping (($/ton) km)

- \(X_{rmct}^{\text{I}}\) :

-

Amount of part c shipped from supplier r to plant m in period t for SC1 (ton)

- \(X_{snct}^{\text{II}}\) :

-

Amount of part c shipped from supplier s to plant n in period t for SC2 (ton)

- \(X_{imct}^{\text{I}}\) :

-

Amount of part c shipped from common supplier i to plant m in period t for SC1 (ton)

- \(X_{inct}^{\text{I}}\) :

-

Amount of part c shipped from common supplier i to plant n in period t for SC2 (ton)

- \(Y_{mut}^{\text{I}}\) :

-

Amount of product shipped from plant m to customer u in period t for SC1 (ton)

- \(Y_{nvt}^{\text{II}}\) :

-

Amount of product shipped from plant n to customer v in period t or SC2 (ton)

- \(W_{ujt}^{\text{I}}\) :

-

Amount of product shipped from customer u to common collection centre j in period t for SC1 (ton)

- \(W_{vjt}^{\text{II}}\) :

-

Amount of product shipped from customer v to common collection centre j in period t for SC2 (ton)

- \(Z_{jmct}^{\text{I}}\) :

-

Amount of part c shipped from common collection centre j to plant m in period t for SC1 (ton)

- \(Z_{jnct}^{\text{II}}\) :

-

Amount of part c shipped from common collection centre j to plant n in period t for SC2 (ton)

- \(Q_{mt}^{\text{I}}\) :

-

If plant m is open in period t, 1; otherwise, 0 for SC1

- \(Q_{nt}^{\text{II}}\) :

-

If plant n is open in period t, 1; otherwise, 0 for SC2

- QC jt :

-

If common collection centre j is open in period t, 1; otherwise, 0

- \({\text{Cinv}}_{mct}^{\text{I}}\) :

-

Inventory amount of part c held in plant m in period t for SC1 (ton)

- \({\text{Cinv}}_{nct}^{\text{II}}\) :

-

Inventory amount of part c held in plant n in period t for SC2 (ton)

References

Sabri, E.H., Beamon, B.M.: A multi-objective approach to simultaneous strategic and operational planning in supply chain design. Omega 28(5), 581–598 (2000)

Üster, H., Easwaran, G., Akçali, E., Çetinkaya, S.: Benders decomposition with alternative multiple cuts for a multi-product closed-loop supply chain network design model. Nav. Res. Logist. 54(8), 890–907 (2007)

Wei, J., Govindan, K., Li, Y., Zhao, J.: Pricing and collecting decisions in a closed-loop supply chain with symmetric and asymmetric information. Comput. Oper. Res. 54, 257–265 (2015)

Mitra, S., Webster, S.: Competition in remanufacturing and the effects of government subsidies. Int. J. Prod. Econ. 111(2), 287–298 (2008)

El Omri, A., El Omri: Cooperation in supply chains: alliance formation and profit allocation among independent firms. Ecole Centrale Paris (2009)

Rezapour, S., Farahani, R.Z., Fahimnia, B., Govindan, K., Mansouri, Y.: Competitive closed-loop supply chain network design with price-dependent demands. J. Clean. Prod. 93, 251–272 (2015)

Govindan, K., Soleimani, H., Kannan, D.: Reverse logistics and closed-loop supply chain: a comprehensive review to explore the future. Eur. J. Oper. Res. 240(3), 603–626 (2015)

Subulan, K., Baykasoğlu, A., Özsoydan, F.B., Taşan, A.S., Selim, H.: A case-oriented approach to a lead/acid battery closed-loop supply chain network design under risk and uncertainty. J. Manuf. Syst. 37(1), 340–361 (2015)

Fahimnia, B., Sarkis, J., Davarzani, H.: Green supply chain management: a review and bibliometric analysis. Int. J. Prod. Econ. 162, 101–114 (2015). doi:10.1016/j.ijpe.2015.01.003

Ahlatcioglu, M., Tiryaki, F.: Interactive fuzzy programming for decentralized two-level linear fractional programming (DTLLFP) problems. Omega 35(4), 432–450 (2007)

Selim, H., Ozkarahan, I.: A supply chain distribution network design model: an interactive fuzzy goal programming-based solution approach. Int. J. Adv. Manuf. Technol. 36(3–4), 401–418 (2008)

Torabi, S.A., Hassini, E.: An interactive possibilistic programming approach for multiple objective supply chain master planning. Fuzzy Sets Syst. 159(2), 193–214 (2008)

Özceylan, E., Paksoy, T.: Interactive fuzzy programming approaches to the strategic and tactical planning of a closed-loop supply chain under uncertainty. Int. J. Prod. Res. 52(8), 2363–2387 (2014)

Min, H.: Strategic Alliances and Partnerships. http://www.ftpress.com/articles/article.aspx?p=2359420&seqNum=5 (2015). Accessed 01 Dec 2015

Zimmermann, H.J.: Fuzzy programming and linear programming with several objective functions. Fuzzy Sets Syst. 1(1), 45–55 (1978)

Zimmermann, H.-J.: Description and optimization of fuzzy systems. Int. J. Gen Syst 2(4), 209–215 (1976)

Tzeng, G.H., Huang, J.J.: Multiple Attribute Decision Making: Methods and Applications. Taylor & Francis, Boca Raton (2011)

Buckley, J.J.: Ranking alternatives using fuzzy numbers. Fuzzy Sets Syst. 15(1), 21–31 (1985)

Author information

Authors and Affiliations

Corresponding author

Appendix 1: Detailed Explanation of Mathematical Equations

Appendix 1: Detailed Explanation of Mathematical Equations

1.1 The Objective Functions

The objective functions are changed according to the DMs. While the objective functions of DM1 and DM2 consist of four different components, the objective function of DM3 has only one component, and the objective function of DM4 has three different components. The first component of the DM1 objective function (Eq. 1) is total transportation cost, which includes transportation costs on each arc of the SC1. The second component (Eq. 2) of the objective function is the purchasing cost of parts. The third component (Eq. 3) calculates fixed costs for operating the plants in SC1. The inventory costs, which hold the parts in the plants, are presented as the fourth component (Eq. 4). The objective function of DM2 minimizes the total costs. The total costs of the DM2 are derived from the transportation costs (Eq. 5), purchasing costs of the parts (Eq. 6), opening costs of the plants (Eq. 7), and the part inventory costs (Eq. 8). The objective function of DM3 maximizes the total selling price of the parts (Eq. 9). The objective function of DM4 maximizes the total profit. It is obtained by subtracting the transportation costs and opening costs of common collection centres from the total sales price of the parts (Eq. 10).

1.2 The Constraints

Constraint (11) ensures that the total quantity of the parts sent from suppliers to the plants in SC1 should be less than or equal to the capacity of parts of those suppliers during any period. Similarly, Constraint (12) ensures that the total quantity of parts sent from suppliers to the plants in SC2 should be less than or equal to the capacity of the parts of those suppliers during any period. Constraint (13) assures that the total quantity of parts sent from common suppliers to the plants should be less than or equal to the capacity of the parts of those common suppliers during any period. Constraints (14)–(15) ensure that the total quantity of products sent from plants to the customers at SC1 and SC2 should be less than or equal to the capacity of parts of those plants during any period in SC1 and SC2, respectively. Constraints (16)–(17) maintain that the demands of customers for the products must be satisfied in each period in SC1 and SC2, respectively. Constraint (18) guarantees that the total quantity of used products collected from customers should be less than or equal to the capacity of the products of common collection centres during any period. Constraints (19)–(20) guarantee that the flow balance of used products collected from customers after one period usage is equal to the total amount of shipped products from plants to customers in SC1 and SC2. Constraints (21)–(22) guarantee the total used products collected from customers and shipped to collection centres must be equal to the used products that are shipped from collection centres to plants. Constraints (23)–(24) calculate that the amount of inventory of total purchased parts from suppliers, total purchased parts from common suppliers, total used products that are shipped from collection centres to plants, and total amount of inventory in plants in the prior period are equal to the total assembled and shipped products from plants to customers during any period in SC1 and SC2, respectively. Constraints (25)–(26) assure that the amount of inventory parts in the plants must be greater than the demand of customers during any period in SC1 and SC2, respectively. Constraints (27)–(28) assure that the amount of inventory held in the plants should be less than or equal to the capacity of those plants during any period in SC1 and SC2, respectively. Constraints (29)–(40) preserve the non-negativity of the decision variables. Constraints (41)–(43) represent the binary variables.

Rights and permissions

About this article

Cite this article

Çalık, A., Paksoy, T., Yıldızbaşı, A. et al. A Decentralized Model for Allied Closed-Loop Supply Chains: Comparative Analysis of Interactive Fuzzy Programming Approaches. Int. J. Fuzzy Syst. 19, 367–382 (2017). https://doi.org/10.1007/s40815-016-0167-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40815-016-0167-z