Abstract

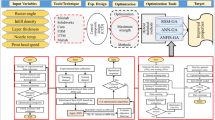

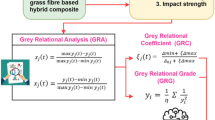

The study focused on assessing selected organic fillers’ impact (periwinkle and clam shells) on the physicochemical and mechanical properties of polyester composites. The tensile, compressive, flexural and Brinell hardness tests were respectively carried out in accordance to ASTM standards. The methods involved grinding and sieve analysis of the shells, material preparation, and Taguchi robust design aided by Plackett–Burman screening. Signal-to-noise ratio analysis guided composite fabrication. The process control variables were grouped in terms of particles sizes: 75, 150, 425 µm, weight fraction: 5%, 20%, 40% and material thickness: 5, 15, 25 mm. The Artificial Neural Network (ANN) training was carried out using MATLAB R2013a and the cascade-forward back-propagation architecture while Adaptive network-based fuzzy system (ANFIS) which is a well-known hybrid artificial intelligence model was subsequently applied. The geometrical model of 9 mm FMJ armour piercing ammunition projectile and the armour plate was modeled using a commercial finite element software package (ANSYS v14) suitable for high velocity impact. The Finite Element Analysis (FEA) further investigates the deformation, elastic strain, and stress response of clam and periwinkle reinforced composites under ballistic impact. Scanning Electron Microscopy (SEM), Fourier transform infrared (FTIR), Differential scanning calorimetry (DSC) and Thermogravimetric analysis (TGA)/Differential thermal analysis (DTA) were deployed to further study the morphology, chemical composition, phase transitions and thermal stability of the optimal material. The results revealed that the clam shell reinforced composite have mechanical responses of 11.038 MPa, 17.07 MPa, 40.2 MPa, and 69.62 N/mm for tensile, compressive, flexural, and hardness strength respectively. While the periwinkle shell reinforced composite has mechanical responses of 16.111 MPa, 17.173 MPa, 39.7 MPa, and 63.57 N/mm for tensile, compressive, flexural, and hardness strength respectively. FEA results indicate decreasing deformation, elastic strain, and stress with increasing material thickness. The investigation carried out indicated the impact of the organic fillers and showed that the new material properties depend on the reinforcement combinations of control parameters.

Similar content being viewed by others

Data Availability

The dataset generated and analyzed during the current study are available from the corresponding author on reasonable request.

References

Adah PU, Nuhu AA, Salawu AA, Hassan AB, Ubi PA. Characterization of periwinkle shell ash reinforced polymer composite for automotive application. FUDMA J Sci. 2024;8(1):83–92.

Agbaje OBA, Wirth R, Morales LFG, Shirai K, Kosnik M, Watanabe T, Jacob DE. Architecture of crossed-lamellar bivalve shells: the southern giant clam (Tridacna derasa, Röding, 1798). R Soc Open Sci. 2017;4(9): 170622.

Águila-Almanza E, Hernández-Cocoletzi H, Rubio-Rosas E, Calleja-González M, Lim HR, Khoo KS, Singh V, Maldonado-Montiel JC, Show PL. Recuperation and characterization of calcium carbonate from residual oyster and clamshells and their incorporation into a residential finish. Chemosphere. 2022;288: 132550.

Aimikhe VJ, Lekia GB. An overview of the applications of periwinkle (Tympanotonus fuscatus) shells. Curr J Appl Sci Technol. 2021;40(18):31–58.

Alghamdi HM, Abutalib MM, Mannaa MA, Nur O, Abdelrazek EM, Rajeh A. Modification and development of high bioactivities and environmentally safe polymer nanocomposites doped by Ni/ZnO nanohybrid for food packaging applications. J Market Res. 2022;19:3421–32.

Al-Maharma AY, Patil SP, Markert B. Effects of porosity on the mechanical properties of additively manufactured components: a critical review. Mater Res Express. 2020;7(12): 122001.

Anand KJ, Ekbote T. Optimization of clamshell content for improved properties in bamboo-epoxy composites. Frat Integr Strutt. 2024;18(69):29–42.

Ani OI, Onoh GN, Akpor OJ, Ukpai CA. Design, development and performance evaluation of a mobile rice threshing machine. Int J Emerg Trends Eng Dev. 2020;10:7–17.

Asyraf MRM, Nurazzi NM, Norrrahim MNF, Hazrati KZ, Ghani A, Sabaruddin FA, et al. Thermal properties of oil palm lignocellulosic fibre reinforced polymer composites: a comprehensive review on thermogravimetry analysis. Cellulose. 2023;30(5):2753–90.

Baloyi RB, Ncube S, Moyo M, Nkiwane L, Dzingai P. Analysis of the properties of a glass/sisal/polyester composite. Sci Rep. 2021;11(1):361.

Bamigboye GO, Nworgu AT, Odetoyan AO, Kareem M, Enabulele DO, Bassey DE. Sustainable use of seashells as binder in concrete production: prospect and challenges. J Build Eng. 2021;34: 101864.

Bao Y, Gao X, Wu Y, Sun M, Li G. Research progress of armor protection materials. J Phys Conf Ser. 2021;1855(1):012035.

Benzait Z, Trabzon L. A review of recent research on materials used in polymer–matrix composites for body armor application. J Compos Mater. 2018;52(23):3241–63.

Bishop CM. Neural networks for pattern recognition. Oxford: Oxford University Press; 1995.

Box GE, Hunter WH, Hunter S. Statistics for experimenters, vol. 664. New York: John Wiley and Sons; 1978.

Box GE, Wilson KB. On the experimental attainment of optimum conditions. In: Breakthroughs in statistics: methodology and distribution. New York, NY: Springer; 1992. p. 270–310.

Breiman L. Random forests. Mach Learn. 2001;45:5–32.

Cortes C, Vapnik V. Support-vector networks. Mach Learn. 1995;20:273–97.

David Müzel S, Bonhin EP, Guimarães NM, Guidi ES. Application of the finite element method in the analysis of composite materials: a review. Polymers. 2020;12(4):818.

Dinesh S, Kumaran P, Mohanamurugan S, Vijay R, Singaravelu DL, Vinod A, Sanjay MR, Siengchin S, Bhat KS. Influence of wood dust fillers on the mechanical, thermal, water absorption and biodegradation characteristics of jute fiber epoxy composites. J Polym Res. 2020;27:1–13.

Dong G, Wijaya G, Tang Y, Zhao YF. Optimizing process parameters of fused deposition modeling by Taguchi method for the fabrication of lattice structures. Addit Manuf. 2018;19:62–72.

El-Wazery MS, El-Elamy MI, Zoalfakar SH. Mechanical properties of glass fiber reinforced polyester composites. Int J Appl Sci Eng. 2017;14(3):121–31.

Etim RK, Ekpo DU, Ebong UB, Usanga IN. Influence of periwinkle shell ash on the strength properties of cement-stabilized lateritic soil. Int J Pavement Res Technol. 2021. https://doi.org/10.1007/s42947-021-00072-8.

Eziefula UG, Obiechefu GC, Charles ME. Use of periwinkle shell by-products in Portland cement-based materials: an overview. Int J Environ Waste Manage. 2020;26(3):362–88.

Femi-Oyetoro J. Prediction of flexural properties for additively manufactured short carbon fiber reinforced composites using machine learning techniques. Master’s thesis, Tennessee Technological University; 2021.

Fisher RA. Statistical methods for research workers, vol. 5. Scotland: Oliver and Boyd; 1928.

Freund Y, Schapire RE. A decision-theoretic generalization of on-line learning and an application to boosting. J Comput Syst Sci. 1997;55(1):119–39.

Gul H, Shah AUHA, Gul S, Bilal S. Analysis of thermal decomposition kinetics and calculation of activation energy for degradation of polyaniline-graphene oxide composites-synergistic reinforcement on thermal stability. Iran J Chem Chem Eng. 2022;41(3):875–89.

Hayeemasae N, Soontaranon S, Masa A. Comparative investigation of nano-sized silica and micrometer-sized calcium carbonate on structure and properties of natural rubber composites. Polymers. 2024;16(8):1051.

He K, Zhang X, Ren S, Sun J. Deep residual learning for image recognition. In Proceedings of the IEEE conference on computer vision and pattern recognition; 2016. pp. 770–778.

Hochreiter S, Schmidhuber J. Long short-term memory. Neural Comput. 1997;9(8):1735–80.

Hubbe MA, Grigsby W. From nanocellulose to wood particles: a review of particle size vs. the properties of plastic composites reinforced with cellulose-based entities. Bioresources. 2020;15(1):2030–81.

Hyde A, He J, Cui X, Lua J, Liu L. Effects of microvoids on strength of unidirectional fiber-reinforced composite materials. Compos B Eng. 2020;187: 107844.

Ihueze CC, Okafor CE, Obuka SN, Abdulrahman J, Onwurah UO. Integrity and cost evaluation of natural fibers/HDPE composite tailored for piping applications. J Thermoplast Compos Mater. 2023;36(1):372–98.

Ihueze CC, Oluleye AE, Okafor CE, Obele CM, Abdulrahman J, Obuka S, Ajemba R. Plantain fibre particle reinforced HDPE (PFPRHDPE) for gas line piping design. Int J Plast Technol. 2017;21:370–96.

Ihueze CC, Onwurah UO, Okafor CE, Obuka NS, Okpala CC, Okoli NC, Nwankwo CO, Kingsley-Omoyibo QO. Robust design and setting process and material parameters for electrical cable insulation. Int J Adv Manuf Technol. 2023. https://doi.org/10.1007/s00170-023-11359-4.

Ikechukwu IF, Onwuka OS, Nwogu MC. Production of periwinkle shell reinforced grindstone. J Appl Sci Environ Manage. 2022;26(6):1157–62.

Jang JS. ANFIS: adaptive-network-based fuzzy inference system. IEEE Trans Syst Man Cybern. 1993;23(3):665–85.

Jena H, Panigrahi A, Jena M. Mechanical property of jute fibre reinforced polymer composite filled with clam shell filler: a marine waste. Adv Mater Process Technol. 2023;9(1):75–91.

Khan K, Iqbal M, Salami BA, Amin MN, Ahamd I, Alabdullah AA, Arab AMA, Jalal FE. Estimating flexural strength of FRP reinforced beam using artificial neural network and random forest prediction models. Polymers. 2022;14(11):2270.

Khora SS. Seafood-associated shellfish allergy: a comprehensive review. Immunol Invest. 2016;45(6):504–30.

Klomklao S, Poonsin T, Benjakul S, Simpson BK. By products from shellfish harvesting and processing. In: By products from agriculture and fisheries: adding value for food, feed, pharma, and fuels. New Jersey: Wiley; 2019. p. 219–57.

Koller D, Friedman N. Probabilistic graphical models: principles and techniques. London: MIT Press; 2009.

Kuldeep B, Ravikumar KP, Guruprasad BS, Tasneem HA, Ashrith HS, Shree N, Ali MM, Bashir MN, Ahamad T. A novel composite connecting rod: study on mechanical and dynamic behaviour through experimental and finite element approach. Composites C Open Access. 2023;12: 100413.

Kumar M, Jena H. Impact of process parameters in drilling of glass epoxy composite with clam shell and cenosphere filler: a comparative analysis. Proc Inst Mech Eng C J Mech Eng Sci. 2024. https://doi.org/10.1177/09544062241235090.

Lakshmi Narayana S, Gopalan V. Mechanical characterization of particle reinforced jute fiber composite and development of hybrid Grey-ANFIS predictive model. Journal of Natural Fibers. 2023;20(1):2167033.

Leprince J, Palin WM, Mullier T, Devaux J, Vreven J, Leloup G. Investigating filler morphology and mechanical properties of new low-shrinkage resin composite types. J Oral Rehabil. 2010;37(5):364–76.

Li A, Huang M, Hu D, Tang Z, Xu J, Li Y, Zhang X, Chen X, Wang G. Polydopamine-coated metal-organic framework-based composite phase change materials for photothermal conversion and storage. Chin Chem Lett. 2023;34(8): 107916.

Liang Y, Zhao Q, Li X, Zhang Z, Ren L. Study of the microstructure and mechanical properties of white clam shell. Micron. 2016;87:10–7.

Liu Y, Zhang HT, Tafsirojjaman T, Dogar AUR, AlAjarmeh O, Yue QR, Manalo A. A novel technique to improve the compressive strength and ductility of glass fiber reinforced polymer (GFRP) composite bars. Constr Build Mater. 2022;326: 126782.

Loy CW, Amin Matori K, Lim WF, Schmid S, Zainuddin N, Abdul Wahab Z, Nadakkavil Alassan Z, Mohd Zaid MH. Effects of calcination on the crystallography and nonbiogenic aragonite formation of ark clam shell under ambient condition. Adv Mater Sci Eng. 2016;2016(1):2914368.

Marinkovic FS, Popovic DM, Jovanovic JD, Stankovic BS, Adnadjevic BK. Methods for quantitative determination of filler weight fraction and filler dispersion degree in polymer composites: example of low-density polyethylene and NaA zeolite composite. Appl Phys A. 2019;125:1–9.

Mbakop RS, Lebrun G, Brouillette F. Effect of compaction parameters on preform permeability and mechanical properties of unidirectional flax fiber composites. Compos. B Eng. 2019;176:107083.

McLachlan GJ. Discriminant analysis and statistical pattern recognition. New Jersey: John Wiley & Sons; 2005.

Montgomery DC. Design and Analysis of Experiments. New York: John Wiley and Sons; 2001.

Muthukumar C, Krishnasamy S, Thiagamani SMK, Nagarajan R, Siengchin S. Thermal characterization of the natural fiber-based hybrid composites: an overview. In: Natural fiber-reinforced composites: thermal properties and applications. New Jersey: Wiley; 2022. p. 1–15.

Nandiyanto ABD, Fitriani AF, Pradana RA, Ragadhita R, Azzaoui K, Piantari E. Green innovation in brake pad production: harnessing teak powder and clam shells as sustainable alternatives for subtractive residual waste. Moroccan J Chem. 2024;12(2):714–33.

Nurazzi NM, Asyraf MRM, Khalina A, Abdullah N, Aisyah HA, Rafiqah SA, Sabaruddin FA, Kamarudin SH, Norrrahim MNF, Ilyas RA, Sapuan SM. A review on natural fiber reinforced polymer composite for bullet proof and ballistic applications. Polymers. 2021;13(4):646.

Nurazzi NM, Khalina A, Sapuan SM, Ilyas RA, Rafiqah SA, Hanafee ZM. Thermal properties of treated sugar palm yarn/glass fiber reinforced unsaturated polyester hybrid composites. J Market Res. 2020;9(2):1606–18.

Odili CC, Philips Gbenebor O, Adekola Haffner H, Oluropo Adeosun S. A morphological characterization of high yield chitin from periwinkle shells. J Cast Mater Eng. 2021;5(4):61–5.

Oghenerukewve PO. Mechanical properties of alkaline modified snail and groundnut shells fillers reinforced glass fiber epoxy composites. 2024. NIPES J Sci Technol Res. https://doi.org/10.5281/zenodo.11017974.

Okafor CE, Ihueze CC. The graft of ANN-FEM technique in macro-mechanics of multi-oriented natural fiber/polyester laminates. Mech Adv Compos Struct. 2021;8(1):51–68.

Okafor CE, Iweriolor S, Ani OI, Ahmad S, Mehfuz S, Ekwueme GO, Chukwumuanya OE, Abonyi SE, Ekengwu IE, Chikelu OP. Advances in machine learning-aided design of reinforced polymer composite and hybrid material systems. Hybrid Adv. 2023;2: 100026.

Okafor CE, Okafor EJ, Obodoeze JJ, Ihueze CC. Characteristics and reliability of polyurethane wood ash composites for packaging and containerisation applications. J Mater Sci Res Rev. 2018;1(3):98–107.

Okafor CE, Okpe DU, Ani OI, Okonkwo UC. Development of carbonized wood/silicon dioxide composite tailored for single-density shoe sole manufacturing. Mater Today Commun. 2022;32: 104184.

Okafor CE, Onovo AC, Ani OI, Obele CM, Dziki D, Ihueze CC, Okonkwo UC. Mathematical study of bio-fibre comminution process as first step towards valorization of post-harvest waste materials. Clean Mater. 2022;4: 100067.

Okafor CE, Onovo AC, Ihueze CC. Predictive energy requirement models in bio-fiber comminution process. SN Appl Sci. 2020;2:1–16.

Okafor CE, Onovo AC, Imoisili PE, Kulkarni KM, Ihueze CC. Optimal route to robust hybridization of banana-coir fiber particulate in polymer matrix for automotive applications. Materialia. 2021;16:101098. https://doi.org/10.1016/j.mtla.2021.101098.

Onuoha C, Onyemaobi OO, Anyakwo CN, Onuegbu GC. Effect of filler content and particle size on the mechanical properties of corn cob powder filled recycled polypropylene composites. Am J Eng Res. 2017;6:72–9.

Oudi AH, Irankhah A. Screening of important factors affecting the process of ammonia synthesis by Plackett–Burman method and process optimization with RSM. Iran J Chem Eng (IJChE). 2022;19(2):3–20.

Plackett RL, Burman JP. The design of optimum multifactorial experiments. Biometrika. 1946;33(4):305–25.

Pokharel P, Pant B, Pokhrel K, Pant HR, Lim JG, Kim HY, Choi S. Effects of functional groups on the graphene sheet for improving the thermomechanical properties of polyurethane nanocomposites. Compos B Eng. 2015;78:192–201.

Praveenkumara J, Madhu P, Yashas Gowda TG, Sanjay MR, Siengchin S. A comprehensive review on the effect of synthetic filler materials on fiber-reinforced hybrid polymer composites. J Textile Inst. 2022;113(7):1231–9.

Qian C, Tan RK, Ye W. Design of architectured composite materials with an efficient, adaptive artificial neural network-based generative design method. Acta Mater. 2022;225: 117548.

Quinlan JR. Induction of decision trees. Mach Learn. 1986;1:81–106.

Ravindran L, Sreekala MS, Kumar SA, Thomas S. A comprehensive review on phenol–formaldehyde resin-based composites and foams. Polym Compos. 2022;43(12):8602–21.

Ribeiro GD, Hiranobe CT, da Silva JFR, Torres GB, Paim LL, Job AE, Cabrera FC, dos Santos RJ. Physical–mechanical properties of Chartwell® coupling agent-treated calcium carbonate and silica-reinforced hybrid natural rubber composites. Crystals. 2022;12(11):1552.

Rumelhart DE, Hinton GE, Williams RJ. Learning representations by back-propagating errors. Nature. 1986;323(6088):533–6.

Sápi Z, Butler R, Rhead A. Filler materials in composite out-of-plane joints—a review. Compos Struct. 2019;207:787–800.

Sharma A, Kumar SA, Kushvaha V. Effect of aspect ratio on dynamic fracture toughness of particulate polymer composite using artificial neural network. Eng Fract Mech. 2020;228: 106907.

Sharma N, Kumar S, Singh KK. Taguchi’s DOE and artificial neural network analysis for the prediction of tribological performance of graphene nano-platelets filled glass fiber reinforced epoxy composites under the dry sliding condition. Tribol Int. 2022;172: 107580.

Shuaib-babata YL, Ambali IO, Abdulqadir LB, Ibrahim HK, Aremu INA, Ibraheem TO. Production of abrasive sandpaper using periwinkle shells and crab shells. Int J Eng Mater Manuf. 2020;5(2):55–61.

Sibanda NC, Ndlovu LN, Ncube SR, Hlabano N. Development and evaluation of physical and mechanical properties on talc filled sisal/polyester composites. Emerg Trends Chem Eng. 2018;5(2):27–35.

Singh S, Pflug L, Mergheim J, Stingl M. Robust design optimization for enhancing delamination resistance of composites. Int J Numer Meth Eng. 2023;124(6):1381–404.

Siraj S, Al-Marzouqi AH, Iqbal MZ, Ahmed W. Impact of micro silica filler particle size on mechanical properties of polymeric based composite material. Polymers. 2022;14(22):4830.

Stephen C, Behara SR, Shivamurthy B, Selvam R, Kannan S, Abbadi M. Finite element study on the influence of fiber orientation on the high velocity impact behavior of fiber reinforced polymer composites. Int J Interact Des Manuf (IJIDeM). 2022;16(2):459–68.

Taguchi G. Introduction to quality engineering: designing quality into products and processes. Tokyo: Asian Productivity Organization; 1986.

Tavakoli M, Heydari AA, Zain Al-Thalabi SH. Control charts for exponentially distributed characteristics: SD, ED, ESD with Taguchi’s loss function. Appl Artif Intell. 2024;38(1):2322362.

Umaru HI, Ishiaku US, Yakubu MK, Kogo AA. Effect of particle size on tensile properties and density of Delonix regia seed particles filled unsaturated polyester resin composites. Sci World J. 2022;17(4):507–11.

Umunakwe R, Okoye OC, Nwigwe US, Oyetunji A, Umunakwe IJ. Effects of stirring time and particles preheating on porosity, mechanical properties and microstructure of periwinkle shell-aluminium metal matrix composite (PPS-ALMMC). Ann Fac Eng Hunedoara. 2017;15(3):133.

Vetter J, Beneder S, Kandler M, Feyer F, Körner C, Schmidt M. Impact of particle size distribution in the preform on thermal conductivity, Vickers hardness and tensile strength of copper-infiltrated AISI H11 tool steel. Materials. 2023;16(7):2659.

Wang P, Wang Y, Hong P, Zhou C. Di-aldehyde starch crystal: a novel bio-crosslinker for strengthening the structure and physio-chemical properties of gelatin-based films. Food Biosci. 2021;43: 101308.

Wang WR, Wang WL, Yeh JW. Phases, microstructure and mechanical properties of AlxCoCrFeNi high-entropy alloys at elevated temperatures. J Alloy Compd. 2014;589:143–52.

Wu G, Zhang Q, Yang X, Huang Z, Sha W. Effects of particle/matrix interface and strengthening mechanisms on the mechanical properties of metal matrix composites. Compos Interfaces. 2014;21(5):415–29.

Yaashikaa PR, Kumar PS, Karishma SJER. Review on biopolymers and composites—evolving material as adsorbents in removal of environmental pollutants. Environ Res. 2022;212: 113114.

Yadav R, Islam A, Kumar Dwivedi V. Wear and microstructure analysis of aluminium based composite using eggshell and rice husk ash as reinforcement. World J Eng. 2024;21(1):186–93.

Yaro A, Kuburi L, Moshood MA. Influence of Kaolin particulate and Luffa cylindrica fiber on the mechanical properties polyester matrix. Int J Adv Manuf Technol. 2021;116:139–44.

Yohannes B, Gonzalez M, Abebe A, Sprockel O, Nikfar F, Kang S, Cuitino AM. The role of fine particles on compaction and tensile strength of pharmaceutical powders. Powder Technol. 2015;274:372–8.

Yuan B, Bao C, Song L, Hong N, Liew KM, Hu Y. Preparation of functionalized graphene oxide/polypropylene nanocomposite with significantly improved thermal stability and studies on the crystallization behavior and mechanical properties. Chem Eng J. 2014;237:411–20.

Zaghloul MMY, Steel K, Veidt M, Heitzmann MT. Wear behaviour of polymeric materials reinforced with man-made fibres: a comprehensive review about fibre volume fraction influence on wear performance. J Reinf Plast Compos. 2022;41(5–6):215–41.

Zaghloul MY, Zaghloul MMY, Zaghloul MMY. Influence of stress level and fibre volume fraction on fatigue performance of glass fibre-reinforced polyester composites. Polymers. 2022;14(13):2662.

Zárate-Ramírez LS, Romero A, Martínez I, Bengoechea C, Partal P, Guerrero A. Effect of aldehydes on thermomechanical properties of gluten-based bioplastics. Food Bioprod Process. 2014;92(1):20–9.

Zhan J, Lu J, Wang D. Review of shell waste reutilization to promote sustainable shellfish aquaculture. Rev Aquac. 2022;14(1):477–88.

Zhao Z, Cao S, Yilmaz E. Effect of layer thickness on the flexural property and microstructure of 3D-printed rhomboid polymer-reinforced cemented tailing composites. Int J Miner Metall Mater. 2023;30(2):236–49.

Zhao C, Goh KL, Lee HP, Yin C, Zhang K, Zhong J. Experimental study and finite element analysis on energy absorption of carbon fiber reinforced composite auxetic structures filled with aluminum foam. Compos Struct. 2023;303: 116319.

Zhou Y, Wu S, Ma Y, Zhang H, Zeng X, Wu F, Liu F, Ryu JE, Guo Z. Recent advances in organic/composite phase change materials for energy storage. ES Energy Environ. 2020;9(12):28–40.

Funding

No funds, grants, or other support was received.

Author information

Authors and Affiliations

Contributions

The manuscript was written through the contributions of all authors. CCI was responsible for the conceptualization of the topic; article gathering and sorting were carried out by CEO, and OEO; manuscript writing and original drafting and formal analysis were carried out by OEO, CEO; writing of reviews and editing were carried out by CCI, OEO; and CEO led the overall research activity. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of Interests

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Research Involving Human and /or Animals

Not applicable.

Informed Consent

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ihueze, C.C., Okafor, C.E. & Omeiza, O.E. Robust Design and Intelligent Modelling of Organic-Based Composites for Armoury Applications. SN COMPUT. SCI. 5, 832 (2024). https://doi.org/10.1007/s42979-024-03199-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42979-024-03199-0