Abstract

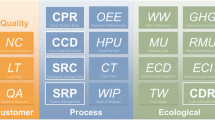

In the Industry 4.0 era, companies need to be highly efficient in utilising their resources to remain competitive. This paper aims to investigate, appraise, and suggest possible improvements for engine mass airflow sensors (MAFS) production at a UK automotive parts manufacturer via combining total quality management (TQM), Six Sigma practices, and total productive maintenance (TPM)—with a focus on overall equipment effectiveness (OEE). The aim is achieved through a systems approach, root cause analyses, and investigating three variables: availability, performance, and quality. Data are extracted both autonomously and manually to determine diverse root causes. The key findings showed that the majority of availability losses stem from maintenance waiting times (16%), performance losses from packaging cycles (31%), and improper housing selection leading to quality rejects (1–3%). Critical appraisal suggested introducing universality amongst staff, continuous improvement via technology, TPM activities, and employing a newly developed optimisation matrix. Also, changes in data infrastructure, reliance on data-driven decision-making instead of traditional methods, and adopting pay-per-use Cloud solutions are advised. These recommendations can effectively monitor processes; reduce underlying losses; boost OEE, total quality, and profits; and support future manufacturing processes. This investigation contributes towards enhancing automotive engine parts production research, presents a novel case study highlighting the effectiveness of combining management techniques to resolve problems in a UK enterprise, and indicates scope for future developments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

The author declares that data supporting the findings of this study are available within the article (and its 15 files).

Abbreviations

- 4M:

-

Man, Machine, Method, Material.

- 5S:

-

Sort, Set in Order, Shine, Standardise, Sustain

- DMAIC:

-

Define, Measure, Analyze, Improve, Control

- DV:

-

Dependent variable

- EV:

-

Electric vehicle

- FTS:

-

Final testing

- FTT:

-

First-time through

- IV:

-

Independent variable

- MAFS:

-

Mass airflow sensor

- MLR:

-

Multiple linear regression

- OEE:

-

Overall equipment efficiency

- PM:

-

Preventive maintenance

- PTM:

-

Production team member

- QV:

-

Quality-Volume

- TPM:

-

Total productive maintenance

- TQM:

-

Total quality management

References

Weckenmann A, Akkasoglu G, Werner T (2015) Quality management – history and trends. The TQM Journal 27(3):281–293

Fragassa C, Pavlovic A, Massimo S (2014) Using a total quality strategy in a new practical approach for improving the product reliability in automotive industry. Int J for Quality Res 8(3):297–310

Yousaf F, Butt DSI, Ahmad DR (2013) Six Sigma implementation to reduce rejection rate of pump casings at local manufacturing company. IOSR J Mech and Civil Engr (IOSR-JMCE) 7(4):96–112

Goh TN (2002) A strategic assessment of Six Sigma. Quality And Relia Engr Int 18(5):403–410

Stahl JE, Gabrielson P, Andersson C, Jönsson M (2012) Dynamic manufacturing costs—describing the dynamic behavior of downtimes from a cost perspective. CIRP J Manuf Sci Technol 5(4):284–295

Ahuja IPS, Khamba JS (2008) Total productive maintenance: literature review and directions. Int J Quality & Relia Mngt 25(7):709–756

Nakajima S (1988) Introduction to TPM, 1st edn. Productivity Press, Cambridge

Katukoori V (1995) Standardizing availability definition. University of New Orleans, New Orleans

Patty AL, Watson K (2009) Downtime variability: the impact of duration-frequency on the performance of serial production systems. Int J Prod Res 48(19):1–11

Salleh NAM, Kasolang S, Jaffar A (2011) Lean TQM automotive factory model system. World Acad of Sc, Engr and Tech 55:627–630

Singh R, Gohil AM, Shah DB, Desai S (2013) Total productive maintenance (TPM) implementation in a machine. Procedia Engr 51:592–599

Ribeiroa IM, Godinab R, Pimentel C et al (2019) Implementing TPM supported by 5S to improve the availability of an automotive production line. Procedia Manufact 38:1574–1581

Swarnakar V, Vinodh S (2016) Deploying Lean Six Sigma framework in an automotive component manufacturing organization. Int J Lean Six Sigma 7(3):267–293

Ruben RB, Vinodh S, Asokan P (2017) Implementation of Lean Six Sigma framework with environmental considerations in an Indian automotive component manufacturing firm: a case study. Planning & Control 28(15):1193–1211

Vinodh S, Gautham SG, Anesh RR (2011) Implementing lean sigma framework in an Indian automotive valves manufacturing organisation: a case study. Prod Planning & Control 22(7):708–722

Bronislav C, Robert B (2014) Lean manufacturing system design based on computer simulation: case study for manufacturing of automotive engine Control Units. In: Modrák V, Semančo P (ed) Handbook of research on design and management of lean production systems. IGI Global, Hershey, PA, pp 89–114

Wang Q, Sowden M, Mileham AR (2013) Modelling human performance within an automotive engine assembly line. Intl J Adv Manufact Tech 68:141–148

Chiabert P, D’Antonio G, Inoyatkhodjaev J et al (2015) Improvement of powertrain mechatronic systems for lean automotive manufacturing. Procedia CIRP 33:53–58

ElMaraghy HA, AlGeddawy T (2012) Co-evolution of products and manufacturing capabilities and application in auto-parts assembly. Flex Serv Manuf J 24:142–170

Omar MA (2011) The automotive body manufacturing systems and processes, 1st edn. John Wiley & Son, Chichester, West Sussex

Syafrudin M, Alfian G, Fitriyani NL, Rhee J (2018) Performance analysis of IoT-based sensor, big data processing, and machine learning model for real-time monitoring system in automotive manufacturing. Sensors 18(9):1–24

Michalos G, Makris S, Papakostas N et al (2010) Automotive assembly technologies review: challenges and outlook for a flexible and adaptive approach. CIRP J Manuf Sci Technol 2(2):81–91

Sazhin O (2013) Novel mass air flow meter for automobile industry based on thermal flow microsensor. Analytical model and microsensor. Flow Meas Instrum 30:60–65

Schneider N, Hecht H, Konzelmann U et al (2013) Hot film air mass meter and method for its manufacture. Robert B GmbH (assignee), United States patent 8,448,508 https://patents.google.com/patent/US8448508

Sakuma N (2014) Thermal fluid flow sensor and method of manufacturing the same. Hitachi AS Ltd (assignee), United States patent 8,714,008. https://patents.google.com/patent/US8714008B2

Yao Y, Chen C, Wang G, Huang L (2010) Method of manufacturing a flow rate sensor. Siargo I (assignee), United States patent 7,765,679. https://patents.google.com/patent/US7765679B2

Noori B, Latifi M (2018) Development of Six Sigma methodology to improve grinding processes: a change management approach. Int J Lean Six Sigma 9(1):50–63

Deloitte Insights (2020) Industry 4.0 in automotive (White Paper). Automotive News 1–28

Sarvankar SG, Yewale SN (2020) Additive manufacturing in automobile industry. International Journal of Research In Aeronautical and Mechanical Engineering 7(4):1–10

Harris M, Ndiaye M, Farrell P (2020) Integration of ‘Industry 4.0’ and ‘Internet of Things’ in the automotive and motorsports: an empirical analysis. SAE Technical Papers 1(5079):1–12

Giampieri A, Ling-Chin J, Ma Z et al (2020) A review of the current automotive manufacturing practice from an energy perspective. Applied Energy 261:114074

Singh K, Ahuja IS (2015) An evaluation of transfusion of TQM-TPM implementation initiative in an Indian manufacturing industry. J Qual Maint Eng 21(2):134–153

Gerritsen BHM (2010) EIS systems and quality management. In: Management association IR (ed) Information resources management: concepts, methodologies, tools and applications. Idea Group Inc (IGI), New York, pp 1989–1990

Willmott P, McCarthy D (2001) TPM - a route to world-class performance, 1st edn. Butterworth-Heinemann, London

Jonsson P, Lesshammar M (1999) Evaluation and improvement of manufacturing performance measurement systems-the role of OEE. Int J Oper Prod Manag 19(1):55–78

Saunders M, Lewis P, Thornhill A (2019) Understanding research philosophy and approaches to theory development. In: Research methods for business students. Pearson Education, Harlow, pp 128–171

Creswell JW (2014) Research design: qualitative, quantitative, and mixed methods approaches, 4th edn. SAGE Publications Inc, Los Angeles

Legg C, Hookway C (2019) Pragmatism, Spring. The Stanford Encyclopedia of Philosophy, Stanford

Osang JE, Udoimuk AB, Etta EB et al (2013) Methods of gathering data for research purpose and applications using IJSER acceptance rate of monthly paper publication. IOSR J Comp Engr (IOSR-JCE) 15(2):59–65

Bryman A, Bell E (2015) Business research methods, 4th edn. Oxford University Press, Oxford

Tracy SJ (2010) Qualitative quality: eight “Big-Tent” criteria for excellent qualitative research. Qual Inq 16(10):837–851

Pimple KD (2002) Six domains of research ethics: a heuristic framework for the responsible conduct of research. Sci Eng Ethics 8(2):191–205

Yin RK (2014) Case study research design and methods, 4th edn. Sage Inc, Thousand Oaks, CA

Gustafsson J (2017) Single case studies vs. multiple case studies: a comparative study. Academy of Business. Engineering and Science, Halmstad University, Sweden, pp 1–15

Singh J, Singh H (2020) Application of lean manufacturing in automotive manufacturing unit. International Journal of Lean Six Sigma 11(1):171–210

Dai Q, Zhong R, Huang GQ et al (2012) Radio frequency identification-enabled real-time manufacturing execution system: a case study in an automotive part manufacture. Int J Comput Integr Manuf 25(1):51–65

Kumar S (2016) Application of Six Sigma in Automobile Industry. International Journal of Exploration in Engineering and Technology (IJEET) 2(1):39–44

Takao MRV, Woldt J, Silva IBd (2017) Six Sigma methodology advantages for small- and medium-sized enterprises: a case study in the plumbing industry in the United States. Adv Mech Eng 9(10):1–10

Huang R (2013) Six Sigma ‘killed’ innovation in 3M. https://www.zdnet.com/article/six-sigma-killed-innovation-in-3m. Accessed 10 December 2020

Nguyen DBL (2020) Study on operation management for eliminate defect on automotive diecasting mass production. Oxford Journal of Technology, Arts, Sciences and Knowledge 1(1):1–12

American Society for Quality (2019) Fishbone diagram. American Society for Quality. https://asq.org/quality-resources/fishbone. Accessed 21 December 2020

Wolniak R (2019) Downtime in the automotive industry production process – cause analysis. Quality Innovation Prosperity 23(2):101–118

Agrahari RS, Dangle PA, Chandratre KV (2015) Implementation of 5S methodology in the small scale industry: a case study. Int J Sci Technol Res 4(4):180–187

Randhawa JS, Ahuja IS (2017) 5S – a quality improvement tool for sustainable performance: literature review and directions. Int J Quality & Relia Mngt 34(3):334–360

Chiarini A (2015) Improvement of OEE performance using a Lean Six Sigma approach: an Italian manufacturing case study. Int J Prod and Quality Mngt 16(4):416–433

Tabor J, Spurek P (2014) Cross-entropy clustering. Pattern Recogn 47(9):3046–3059

Uyanık GK, Güler N (2013) A study on multiple linear regression analysis. Procedia Soc Behav Sci 106:234–240

Büyüköztürk Ş (2002) Faktör analizi: Temel kavramlar ve ölçek geliştirmede kullanımı. Kuram ve uygulamada eğitim yönetimi 32(32):470–483

Zadach T (2013) TRIZ. University of Michigan. http://umich.edu/~scps/html/07chap/html/powerpointpicstriz/Chapter%207%20TRIZ.pdf. Accessed 1 December 2020

Baluch N, Abdullah CS, Mohtar S (2012) TPM and lean maintenance – a critical review. Interdisc J Contemp Resh in Bus 4(2):850–857

Tao F, Qi Q, Liub A, Kusiak A (2018) Data driven smart manufacturing. J Manuf Syst 48(2018):157–169

Deloitte Insights (2018) The Internet of Things. Deloitte. https://www2.deloitte.com/content/dam/insights/us/articles/4420_IoT-primer/DI_IoT-Primer.pdf. Accessed 2 December 2020

AWS (2020) AWS Customer Success. https://aws.amazon.com/solutions/case-studies/amazon/. Accessed 2 December 2020

Google Cloud (2020). Google Cloud customers. https://cloud.google.com/customers/#/products=IoT. Accessed 20 December 2020

May D (2015) BMW case study (video). AWS. https://aws.amazon.com/solutions/casestudies/bmw/. Accessed 14 December 2020

Lowe D, Galhotra B (2018) An overview of pricing models for using cloud services with analysis on pay-per-use model. International Journal of Engineering & Technology 7(3.12):248–254

Gondal UH, Shahbaz M (2012) Interdepartmental communication increases organizational performance keeping HRM as a mediating variable. Asian Economic and Social Society 2(6):127–141

Acknowledgements

Heartiest thanks to Dr. Peter Farrell, Dr. Mark Busfield, Dr. Kondal Kandadi, and the National Centre of Motorsports Engineering (NCME) staff for their diverse contribution towards this paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Harris, M. An Investigation on Engine Mass Airflow Sensor Production via TQM, TPM, and Six Sigma Practices. Oper. Res. Forum 2, 61 (2021). https://doi.org/10.1007/s43069-021-00102-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43069-021-00102-y