Abstract

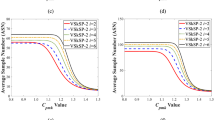

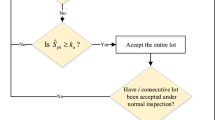

The skip-lot sampling plan (SkSP) is employed in supply chains to decrease the amount of inspection required for submitted lots when they have demonstrated a succession of lots with excellent quality. As only some fractions of lots are examined, the cost of inspection is reduced. With the current abundance of high-yield products, however, the majority of SkSP schemes have been utilized for attributes testing, which does not fully reveal the SkSP’s economic advantages. Thus, on the basis of the process capability index Cpk, the variables SkSP with single sampling as a reference plan (Cpk-SkSP-2) was developed. With management of the lot’s quality and tolerable risks agreeable to both the supplier and the buyer, the Cpk-SkSP-2 were incorporated with acceptance probabilities (rather than asymptotic approximations), which yielded the exact sampling distribution of the Cpk estimator at the specified quality standards. Furthermore, the equilibrium probability for the acceptance of Cpk-SkSP-2 was derived from a Markov chain technique. These treatments enable minimization of the average number of samples required to render more reliable and optimal plan parameters for the inspection of products with a low fraction of defectives. The results are compared with the variables Cpk-based single sampling plans. Finally, a graphical user interface was built on the basis of our proposed Cpk-SkSP-2 procedures and methodologies to facilitate data input, plan selection, criteria computation, and decision-making in practice.

Similar content being viewed by others

References

Aslam M, Balamurali S, Jun CH, Ahmad M (2010) Optimal designing of a skip-lot sampling plan by two point method. Pak J Stat 26(4):585–592

Aslam M, Balamurali S, Jun CH, Ahmad M, Rasool M (2013) Optimal designing of skip-lot sampling plan of type SkSP-2 with group acceptance sampling plan as the reference plan under burr type XII distribution. J Stat Comput Simul 83(1):37–51

Aslam M, Balamurali S, Azam M, Jun CH (2014) Skip-lot sampling plan of type SkSP-2 with two-stage group acceptance sampling plan as reference plan. Commun Stat Simul Comput 43(4):777–789

Balamurali S, Jun CH (2009) Designing of a variables two-plan system by minimizing the average sample number. J Appl Stat 36(10):1159–1172

Balamurali S, Subramani J (2017) Optimal designing of SkSP-2 skip-lot sampling plan for normally distributed quality characteristics. Trans Inst Meas Control. https://doi.org/10.1177/0142331217700466

Boyles RA (1991) The Taguchi capability index. J Qual Technol 23(1):17–26

Dodge HF (1943) A sampling plan for continuous production. Ann Math Stat 14(3):264–279

Dodge HF (1955) Skip-lot sampling plan. Ind Qual Control 11(5):3–5

Evans JR (2005) Total quality-management, organizations and strategy, 4th edn. Edmonton, Thomson

Hillier FS, Lieberman GJ (2001) Introduction to operations research, 7th edn. McGraw Hill, New York

Hsu JIS (1980) An economic design of skip-lot sampling plans. J Qual Technol 12(3):144–149

Kane E (1986) Process capability indices. J Qual Technol 18(1):41–52

Lee AHI, Wu CW, Chen YW (2016) A modified variables repetitive group sampling plan with the consideration of preceding lots information. Ann Oper Res 238(1):355–373

Lepore A, Palumbo B, Castagliola P (2018) A note on decision making method for product acceptance based on process capability indices Cpk and Cpmk. Eur J Oper Res 267(1):393–398

Lieberman GJ, Resnikoff G (1955) Sampling plans for inspection by variables. J Am Stat Assoc 50(270):457–516

Mitra A (1998) Fundamentals of quality control and improvement, 2nd edn. Englewood Cliffs, Prentice-Hall

Montgomery DC (2009) Introduction to statistical quality control, 6th edn. Wiley, New York

Nocedal J, Wright SJ (1999) Numerical optimization: Springer series in operations research. Springer

Pearn WL, Shu MH (2003) Manufacturing capability control for multiple power-distribution switch processes based on modified Cpk-MPPAC. Microelectron Reliab 43(6):963–975

Pearn WL, Wu CW (2006) Critical acceptance values and sample size of a variables sampling plan for very low fraction of defectives. Omega Int J Manag Sci 34:90–101

Pearn WL, Wu CW (2007) An effective decision making method for product acceptance. Omega Int J Manag Sci 35(1):12–21

Perry RL (1973) Skip-lot sampling plans. J Qual Technol 5(3):123–1303

Schilling EG, Neubauer DV (2017) Acceptance sampling in quality control, 3rd edn. CRC Press, New York

Shapiro SS, Wilk MB (1965) An analysis of variance test for normality (complete samples). Biometrika 52(3/4):591–611

Stephens KS, Larson KE (1967) An evaluation of the MIL-STD 105D system of sampling plans. Ind Qual Control 23:310–319

Suresh KK, Kavithamani M (2014) Optimal design of skip lot sampling plan of type SkSP-2 with double sampling plan as the reference plan under generalized exponential distribution. Int J Reliab Appl 15(2):77–84

Vännman K (1997) Distribution and moments in simplified form for a general class of capability indices. Commun Stat Theory Methods 26(1):159–179

Vännman K, Kotz S (1995) A superstructure of capability indices-distributional properties and implications. Scand J Stat 22(4):477–491

Vijayaraghavan R (1994) Construction and selection of skip-lot sampling inspection plans of type SkSP-2 indexed by indifference quality level and maximum allowable percent defective. J Appl Stat 21(5):417–423

Vijayaraghavan R, Soundararajan V (1998) Design and evaluation of skip-lot sampling inspection plans with double sampling plan as the reference plan. J Appl Stat 25(3):341–348

Wu CW, Pearn WL (2008) A variables sampling plan based on Cpmk for product acceptance determination. Eur J Oper Res 184(2):549–560

Wu CW, Pearn WL, Kotz S (2009) An overview of theory and practice on process capability indices for quality assurance. Int J Prod Econ 117(2):338–359

Wu CW, Aslam M, Jun CH (2012) Variables sampling inspection scheme for resubmitted lots based on the process capability index Cpk. Eur J Oper Res 217(3):560–566

Wu CW, Lee AH, Liu SW, Shih MH (2017) Capability-based quick switching sampling system for lot disposition. Appl Math Model 52:131–144

Yum BJ, Kim KW (2011) A bibliography of the literature on process capability indices: 2000–2009. Qual Reliab Eng Int 27(3):251–268

Acknowledgements

This work was partially supported by the Ministry of Science and Technology, Taiwan under Grant Nos. MOST 103-2221-E-007-103-MY3

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, CW., Shu, MH., Wang, PA. et al. Variables skip-lot sampling plans on the basis of process capability index for products with a low fraction of defectives. Comput Stat 36, 1391–1413 (2021). https://doi.org/10.1007/s00180-020-01049-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00180-020-01049-0