Abstract.

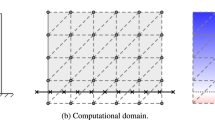

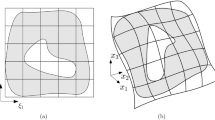

We propose a new method for constructing all-hexahedral finite element meshes. The core of our method is to build up a compatible combinatorial cell complex of hexahedra for a solid body which is topologically a ball, and for which a quadrilateral surface mesh of a certain structure is prescribed. The step-wise creation of the hex complex is guided by the cycle structure of the combinatorial dual of the surface mesh. Our method transforms the graph of the surface mesh iteratively by changing the dual cycle structure until we get the surface mesh of a single hexahedron. Starting with a single hexahedron and reversing the order of the graph transformations, each transformation step can be interpreted as adding one or more hexahedra to the so far created hex complex. Given an arbitrary solid body, we first decompose it into simpler subdomains equivalent to topological balls by adding virtual 2-manifolds. Secondly, we determine a compatible quadrilateral surface mesh for all subdomains created. Then, in the main part we can use the core routine to build up a hex complex for each subdomain independently. The embedding and smoothing of the combinatorial mesh(es) finishes the mesh generation process. First results obtained for complex geometries are encouraging.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Müller–Hannemann, M. Hexahedral Mesh Generation by Successive Dual Cycle Elimination. Engineering with Computers 15, 269–279 (1999). https://doi.org/10.1007/s003660050022

Issue Date:

DOI: https://doi.org/10.1007/s003660050022