Abstract

Today’s modern industry has accepted condition monitoring based on intelligent fault diagnosis of rotating machinery systems to provide precision and sustainability. The conventional signal processing methods are less productive due to the involvement of various noises from different sources in the vibration signal, and therefore, recently fault diagnosis approaches use the artificial intelligent techniques along with the signal processing methods. Thus, motivated by the kurtogram and convolutional neural network (CNN), a novel efficient method for the fault classification of rotating machines is proposed in this paper. Kurtogram is a measure of dispersion for time–frequency energy density which provides additional frequency contents information and as an effect represents a pattern of each fault uniquely. Thus, it inspires to utilize the kurtogram as an input feature vector, and it helps in reducing the task of identifying dominant features to represent the different faults. Hence, this 2D distinct feature vector presented to CNN for fault classification. The various levels of kurtogram are examined by tuning different hyperparameters of CNN to achieve a good feature set for decent performance. The experimental results demonstrate that the proposed method effectively classifies the bearing faults under different operating conditions in comparison to other methods.

Similar content being viewed by others

References

Amar M, Gondal I, Wilson C (2015) Vibration spectrum imaging: a novel bearing fault classification approach. IEEE Trans Ind Electron 62(1):494–502

Antoni J (2006) The spectral kurtosis: a useful tool for characterising non-stationary signals. Mech Syst Signal Process 20(2):282–307

Antoni J (2007) Fast computation of the kurtogram for the detection of transient faults. Mech Syst Signal Process 21(1):108–124

Antoni J, Randall R (2006) The spectral kurtosis: application to the vibratory surveillance and diagnostics of rotating machines. Mech Syst Signal Process 20(2):308–331

Arel I, Rose DC, Karnowski TP (2010) Deep machine learning—a new frontier in artificial intelligence research. IEEE Comput Intell Mag 5(4):13–18

Bellini A, Cocconcelli M, Immovilli F, Rubini R (2008a) Diagnosis of mechanical faults by spectral kurtosis energy. In: 34th annual conference of IEEE industrial electronics (IECON 2008), pp 3079–3083

Bellini A, Filippetti F, Tassoni C, Capolino GA (2008b) Advances in diagnostic techniques for induction machines. IEEE Trans Ind Electron 55(12):4109–4126

Cerrada M, Sánchez RV, Li C, Pacheco F, Cabrera D, de Oliveira JV, Vásquez RE (2018) A review on data-driven fault severity assessment in rolling bearings. Mech Syst Signal Process 99:169–196

Chen B, Zhang Z, Zi Y, He Z, Sun C (2013) Detecting of transient vibration signatures using an improved fast spatial-spectral ensemble kurtosis kurtogram and its applications to mechanical signature analysis of short duration data from rotating machinery. Mech Syst Signal Process 40(1):1–37

Chen Z, Li C, Sanchez RV (2015) Gearbox fault identification and classification with convolutional neural networks. Shock Vib 2015:1–10

CWRU (2009) Case western reserve university bearing data center website. https://csegroups.case.edu/bearingdatacenter/home. Accessed July 2016

Dai X, Gao Z (2013) From model, signal to knowledge: a data-driven perspective of fault detection and diagnosis. IEEE Trans Ind Inform 9(4):2226–2238

Dwyer R (1983) Detection of non-gaussian signals by frequency domain kurtosis estimation. In: International conference on acoustics, speech, and signal processing (ICASSP’83), vol 8. IEEE, pp 607–610

El-Thalji I, Jantunen E (2015) A summary of fault modelling and predictive health monitoring of rolling element bearings. Mech Syst Signal Process 60:252–272

Goodfellow I, Bengio Y, Courville A (2016) Deep learning. MIT Press, Cambridge

Heng R, Nor M (1998) Statistical analysis of sound and vibration signals for monitoring rolling element bearing condition. Appl Acoust 53(1):211–226

Henriquez P, Alonso JB, Ferrer MA, Travieso CM (2014) Review of automatic fault diagnosis systems using audio and vibration signals. IEEE Trans Syst Man Cybern Syst 44(5):642–652

Hosseini M, Pompili D, Elisevich K, Soltanian-Zadeh H (2017) Optimized deep learning for eeg big data and seizure prediction bci via internet of things. IEEE Trans Big Data 3(4):392–404

Immovilli F, Cocconcelli M, Bellini A, Rubini R (2009) Detection of generalized-roughness bearing fault by spectral-kurtosis energy of vibration or current signals. IEEE Trans Ind Electron 56(11):4710–4717

Ince T, Kiranyaz S, Eren L, Askar M, Gabbouj M (2016) Real-time motor fault detection by 1-d convolutional neural networks. IEEE Trans Ind Electron 63(11):7067–7075

Janssens O, Slavkovikj V, Vervisch B, Stockman K, Loccufier M, Verstockt S, de Walle RV, Hoecke SV (2016) Convolutional neural network based fault detection for rotating machinery. J Sound Vib 377:331–345

Jia F, Lei Y, Lin J, Zhou X, Lu N (2016) Deep neural networks: a promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech Syst Signal Process 72:303–315

Kan MS, Tan AC, Mathew J (2015) A review on prognostic techniques for non-stationary and non-linear rotating systems. Mech Syst Signal Process 62:1–20

Kankar P, Sharma SC, Harsha S (2011) Fault diagnosis of ball bearings using machine learning methods. Expert Syst Appl 38(3):1876–1886

Lei Y, Lin J, He Z, Zi Y (2011) Application of an improved kurtogram method for fault diagnosis of rolling element bearings. Mech Syst Signal Process 25(5):1738–1749

Lei Y, Lin J, He Z, Zuo MJ (2013) A review on empirical mode decomposition in fault diagnosis of rotating machinery. Mech Syst Signal Process 35(1):108–126

Liu W, Wang Z, Liu X, Zeng N, Liu Y, Alsaadi FE (2017) A survey of deep neural network architectures and their applications. Neurocomputing 234:11–26

Luo J, Yu D, Liang M (2013) A kurtosis-guided adaptive demodulation technique for bearing fault detection based on tunable-q wavelet transform. Meas Sci Technol 24(5):055,009

Pandya DH, Upadhyay SH, Harsha SP (2014) Fault diagnosis of rolling element bearing by using multinomial logistic regression and wavelet packet transform. Soft Comput 18(2):255–266

Rai A, Upadhyay S (2016) A review on signal processing techniques utilized in the fault diagnosis of rolling element bearings. Tribol Int 96:289–306

Ren S, He K, Girshick R, Sun J (2017) Faster r-cnn: towards real-time object detection with region proposal networks. IEEE Trans Pattern Anal Mach Intell 39(6):1137–1149

Samanta B, Al-Balushi K, Al-Araimi S (2003) Artificial neural networks and support vector machines with genetic algorithm for bearing fault detection. Eng Appl Artif Intell 16(7):657–665

Samanta B, Al-Balushi KR, Al-Araimi SA (2006) Artificial neural networks and genetic algorithm for bearing fault detection. Soft Comput 10(3):264–271

Sugumaran V, Sabareesh G, Ramachandran K (2008) Fault diagnostics of roller bearing using kernel based neighborhood score multi-class support vector machine. Expert Syst Appl 34(4):3090–3098

Sun W, Shao S, Zhao R, Yan R, Zhang X, Chen X (2016) A sparse auto-encoder-based deep neural network approach for induction motor faults classification. Measurement 89:171–178

Sun W, Zhao R, Yan R, Shao S, Chen X (2017) Convolutional discriminative feature learning for induction motor fault diagnosis. IEEE Trans Ind Inform 13(3):1350–1359

Tian J, Morillo C, Pecht MG (2013) Rolling element bearing fault diagnosis using simulated annealing optimized spectral kurtosis. In: IEEE conference on prognostics and health management (PHM 2013), pp 1–5

Vakharia V, Gupta VK, Kankar PK (2016) A comparison of feature ranking techniques for fault diagnosis of ball bearing. Soft Comput 20(4):1601–1619

Wang Y, Xiang J, Markert R, Liang M (2016) Spectral kurtosis for fault detection, diagnosis and prognostics of rotating machines: a review with applications. Mech Syst Signal Process 66:679–698

Wang T, Chu F, Han Q, Kong Y (2017) Compound faults detection in gearbox via meshing resonance and spectral kurtosis methods. J Sound Vib 392:367–381

Wang H, Li Z, Li Y, Gupta B, Choi C (2018) Visual saliency guided complex image retrieval. Pattern Recognit Lett

Xia M, Li T, Liu L, Xu L, de Silva CW (2017a) Intelligent fault diagnosis approach with unsupervised feature learning by stacked denoising autoencoder. IET Sci Meas Technol 11:687–695

Xia M, Li T, Xu L, Liu L, de Silva CW (2017b) Fault diagnosis for rotating machinery using multiple sensors and convolutional neural networks. IEEE/ASME Trans Mechatron PP(99):1–1

Yan R, Gao RX, Chen X (2014) Wavelets for fault diagnosis of rotary machines: a review with applications. Signal Process 96:1–15

Yang J, Sun X, Lai Y, Zheng L, Cheng M (2018) Recognition from web data: a progressive filtering approach. IEEE Trans Image Process 27(11):5303–5315

Zhang Y, Randall R (2009) Rolling element bearing fault diagnosis based on the combination of genetic algorithms and fast kurtogram. Mech Syst Signal Process 23(5):1509–1517

Zhang Y, Song B, Du X, Guizani M (2018) Vehicle tracking using surveillance with multimodal data fusion. IEEE Trans Intell Transp Syst 19(7):2353–2361

Acknowledgements

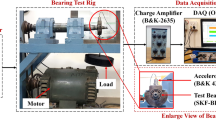

Authors would like to acknowledge TEQIP-II (subcomponent 1.2.1) Centre of Excellence in Complex and Nonlinear Dynamical Systems (CoE-CNDS), VJTI, Matunga, Mumbai-400019, India for providing experimental environment.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Communicated by A.K. Sangaiah, H. Pham, M.-Y. Chen, H. Lu, F. Mercaldo.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Udmale, S.S., Patil, S.S., Phalle, V.M. et al. A bearing vibration data analysis based on spectral kurtosis and ConvNet. Soft Comput 23, 9341–9359 (2019). https://doi.org/10.1007/s00500-018-3644-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00500-018-3644-5