Abstract

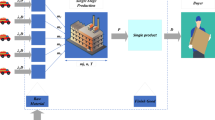

In this paper, a new constrained single-product pricing and inventory model is presented. The goal of the proposed model is to decide on the prices as well as on the inventory and production decisions in order to maximize the total profit. The developed model is a nonlinear programming model which is solved by using hybrid genetic algorithm (HGA) and simulated annealing. Comparison of results obtained from the two algorithms shows that HGA is better. To enhance the performance of our algorithms, we apply the Taguchi experimental design method to tune their parameters. Finally, some recommendations for future developments are presented.

Similar content being viewed by others

References

Abad PL (2003) Optimal pricing and lot-sizing under conditions of perishability, finite production and partial backordering and lost sale. Eur J Oper Res 144:677–685

Abad PL (2000) Optimal lot size for a perishable good under conditions of finite production and partial backordering and lost sale. Comput Ind Eng 38:457–465

Balkhi ZT, Benkherouf L (1996) A production lot size inventory model for deteriorating items and arbitrary production and demand rates. Eur J Oper Res 92:302–309

Balkhi ZT (2001) On a finite horizon production lot size inventory model for deteriorating items: an optimal solution. Eur J Oper Res 132:210–223

Dalfard VM, Ardakani A, Banihashemi TN (2011) Hybrid genetic algorithm for assembly flow-shop scheduling problem with sequence-dependent setup and transportation times. Tech Gazette 18:497–504

Dalfard VM, Kaveh M, Nosratian NE (2012) Two meta-heuristic algorithms for two-echelon location-routing problem with vehicle fleet capacity and maximum route length constraints. Neural Comput Appl (in press). doi:10.1007/s00521-012-1190-0

Edwin Cheng TC, Jian Li CL, Johnny W, Shouyang W (2010) Analysis of pull postponement by EOQ-based models. Int Ser Oper Res Manag Sci 143:19–41

Ghare PM, Schrader GP (1963) A model for an exponentially decaying inventory. J Ind Eng 14:238–243

Goyal SK, Giri BC (2003) The production-inventory problem of a product with time varying demand, production and deterioration rates. Eur J Oper Res 147:557–579

Kyle YL (2006) Dynamic pricing with real-time demand learning. Eur J Oper Res 174:522–538

Song Y, Ray S, Boyaci T (2007) Optimal dynamic joint pricing and inventory control for multiplicative demand with fixed order costs and lost sales. Oper Res 57:245–250

Tsai WH, Hung SJ (2007) Dynamic pricing and revenue management process in Internet retailing under uncertainty: an integrated real options approach. Omega 37:471–481

Tsai YC, Sheen GJ (2008) Dynamic pricing, promotion and replenishment policies for a deteriorating item under permissible delay in payments. Comput Oper Res 35:3562–3580

Teng JT, Ouyang LY, Chen LH (2007) A comparison between two pricing and lot-sizing models with partial backlogging and deteriorated items. Int J Prod Econ 105:190–203

Varma GD, Vettas N (2001) Optimal dynamic pricing with inventories. J Econ Lett 72:335–340

Wei Y (2012) Optimization and optimality of a joint pricing and inventory control policy in periodic-review systems with lost sales. OR Spectrum 34:243–271

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dalfard, V.M., Nosratian, N.E. A new pricing constrained single-product inventory-production model in perishable food for maximizing the total profit. Neural Comput & Applic 24, 735–743 (2014). https://doi.org/10.1007/s00521-012-1279-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-012-1279-5