Abstract

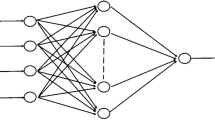

The displacement at various measurement points is a critical indicator that can intuitively reflect the operational properties of a dam. It is important to analyse displacement monitoring data in a timely manner and make reliable predictions of dam safety. This paper proposes a GPR-based model for dam displacement forecasting. The input variables of the monitoring model consider hydraulic factors, thermal factors and irreversible factors, and the output variables are the observed displacements of the dam. An example analysis based on the proposed method is performed on a prototype gravity dam, and the performance of different simple/combined covariance functions is investigated to obtain the optimal choice. Compared to multiple linear regression, radial basis function network (RBFN) and support vector machine (SVM) methods, the results indicate that the GPR-based model with a combined covariance function significantly improves the prediction accuracy. The proposed model can effectively overcome the over-learning and poor robustness issues of approaches such as RBFN and SVM. In addition, the GPR-based forecasting model has the advantages of simplicity in the training process and the capacity to provide a probabilistic output.

Similar content being viewed by others

Abbreviations

- AANN:

-

Auto-associative neural network

- AI:

-

Artificial intelligence

- ANN:

-

Artificial neural network

- BP:

-

Back propagation

- CI:

-

Confidence interval

- FEM:

-

Finite element method

- GP:

-

Gaussian process

- GPR:

-

Gaussian process regression

- HTT:

-

Hydrostatic-thermal-time model

- HST:

-

Hydrostatic-season-time model

- IP:

-

Inverted plumb lines

- LINone:

-

Linear with a bias covariance function

- MAE:

-

Mean absolute error

- MAXE:

-

Maximum absolute error

- ML:

-

Machine learning

- MLR:

-

Multiple linear regression

- NARX:

-

Nonlinear autoregressive exogenous model

- NN:

-

Neural network

- NNone:

-

Neural network covariance function

- PLS:

-

Partial least squares regression

- prodNS:

-

NNone * SEiso

- prodRN:

-

RQiso * NNone

- prodRS:

-

RQiso * SEiso

- R 2 :

-

Determination coefficient

- RBFN:

-

Radial basis function network

- RCCD:

-

Roller-compacted concrete dam

- RMSE:

-

Root mean square error

- RQiso:

-

Rational quadratic covariance function with an isotropic distance measure

- RUL:

-

Remaining useful life

- SEiso:

-

Squared exponential covariance function with isotropic distance measure

- SR:

-

Stepwise regression

- sumRQ:

-

RQiso + SEiso

- sumNS:

-

NNone + SEiso

- sumRN:

-

RQiso + NNone

- SVM:

-

Support vector machine

- SVR:

-

Support vector regression

References

Prakash G, Sadhu A, Narasimhan S et al (2017) Initial service life data towards structural health monitoring of a concrete arch dam. Struct Control Health Monit 25(6):e2036

Mohammad AHA (2018) Risk, reliability, resilience (R3) and beyond in dam engineering: a state-of-the-art review. Int J Disaster Risk Reduct 31:806–831

Chen S, Gu C, Lin C, et al (2018) Safety monitoring model of a super-high concrete dam by using RBF neural network coupled with kernel principal component analysis. Math Probl Eng 2018:1–13

Wang SJ, Gu YC, Pang Q (2017) Experience and prospect of dam surveillance system in China. In: Proceedings of the 85th annual meeting of international commission on large dams

Mata J, Leitão NS, Castro ATD et al (2014) Construction of decision rules for early detection of a developing concrete arch dam failure scenario. A discriminant approach. Comput Struct 142(69):45–53

Salazar F, Morán R, Toledo MÁ et al (2017) Data-based models for the prediction of dam behaviour: a review and some methodological considerations. Arch Comput Methods Eng 24(1):1–21

Kang F, Liu J, Li J et al (2017) Concrete dam deformation prediction model for health monitoring based on extreme learning machine. Struct Control Health Monit 24(10):e1997

Sortis AD, Paoliani P (2007) Statistical analysis and structural identification in concrete dam monitoring. Eng Struct 29(1):110–120

Acosta LE, Lacy MC, Ramos MI et al (2018) Displacements study of an earth fill dam based on high precision geodetic monitoring and numerical modeling. Sensors 18(5):1369

Worden K, Manson G (2007) The application of machine learning to structural health monitoring. Philos Trans 365:515–537

Zhou W, Li SL, Zhou ZW et al (2016) InSAR observation and numerical modeling of the earth-dam displacement of Shuibuya Dam (China). Sensors 8(10):877

Kang F, Li J, Xu Q (2009) Structural inverse analysis by hybrid simplex artificial bee colony algorithms. Comput Struct 87(13):861–870

Ranković V, Novaković A, Grujović N et al (2014) Predicting piezometric water level in dams via artificial neural networks. Neural Comput Appl 24(5):1115–1121

Gu CS, Wu ZR (2006) Safety monitoring of dams and dam foundations—theories & methods and their application. Hohai University Press, Nanjing

Hadi S, Rigoberto B (2018) Emerging artificial intelligence methods in structural engineering. Eng Struct 171:170–189

Wu ZH (2003) Safety monitoring theory & it’s application of hydraulic structures. Higher Education Press, Beijing

Freitag S, Graf W, Kaliske M et al (2011) Prediction of time-dependent structural behaviour with recurrent neural networks for fuzzy data. Comput Struct 89(21–22):1971–1981

Milivojevic M, Milivojevic M, Divac D et al (2013) Adaptive system for dam behavior modeling based on linear regression and genetic algorithms. Adv Eng Softw 65(10):182–190

Fanelli M (1975) Control of dam displacements. Energia Elettrica 52:125–139

Tonini D (1956) Observed behavior of several leakier arch dams. J Power Div 82(12):135–139

Bonaldi P, Fanelli M, Giuseppetti G (1977) Displacement forecasting for concrete dams. Int Water Power Dam Constr 29(9):42–50

Piroddi L, Spinelli W (2004) Long-range nonlinear prediction: a case study. IEEE Conf Decision Control 4:3984–3989

Mata J, Castro ATD, Costa JSD (2014) Constructing statistical models for arch dam deformation. Struct Control Health Monit 21(3):423–437

Bui KTT, Bui DT, Zou J et al (2018) A novel hybrid artificial intelligent approach based on neural fuzzy inference model and particle swarm optimization for horizontal displacement modeling of hydropower dam. Neural Comput Appl 29(12):1495–1506

Wei B, Yuan D, Xu Z et al (2018) Modified hybrid forecast model considering chaotic residual errors for dam deformation. Structural Control and Health Monitoring 25(8):e2188

Karami H, Karimi S, Bonakdari H et al (2018) Predicting discharge coefficient of triangular labyrinth weir using extreme learning machine, artificial neural network and genetic programming. Neural Comput Appl 29(11):983–989

Ahmadi FF (2016) Integration of industrial videogrammetry and artificial neural networks for monitoring and modeling the deformation or displacement of structures. Neural Comput Appl 28(12):3709–3716

Akrami SA, El-Shafie A, Naseri M et al (2014) Rainfall data analyzing using moving average (MA) model and wavelet multi-resolution intelligent model for noise evaluation to improve the forecasting accuracy. Neural Comput Appl 25(7–8):1853–1861

Su HZ, Li X, Yang BB et al (2018) Wavelet support vector machine-based prediction model of dam deformation. Mech Syst Signal Process 110:412–427

Ou JP, Li H (2010) Structural Health Monitoring in mainland China: review and Future Trends. Struct Health Monit 9(3):219–231

Devi VS (2015) Introduction to pattern recognition and machine learning. J Cell Physiol 200(1):71–81

Mata J (2011) Interpretation of concrete dam behaviour with artificial neural network and multiple linear regression models. Eng Struct 33(3):903–910

Kao CY, Loh CH (2013) Monitoring of long-term static deformation data of Fei-Tsui arch dam using artificial neural network-based approaches. Struct Control Health Monit 20(3):282–303

Hu WS, Zhang F, Song L et al (2012) Study of dam deformation model based on neural network. Appl Mech Mater 170–173:2137–2142

Xu GH (2014) Application of rbf neural network in dam deformation prediction. Appl Mech Mater 675–677:261–264

Kang F, Li J, Zhao S et al (2019) Structural health monitoring of concrete dams using long-term air temperature for thermal effect simulation. Eng Struct 180:642–653

Cheng J, Xiong Y (2017) Application of extreme learning machine combination model for dam displacement prediction. Proc Comput Sci 107:373–378

International Commission on Large Dams (2012) Dam surveillance guide. Tech. rep. B-158, ICOLD

Ranković V, Grujović N, Divac D et al (2014) Development of support vector regression identification model for prediction of dam structural behaviour. Struct Saf 48(48):33–39

Su H, Chen Z, Wen Z (2016) Performance improvement method of support vector machine-based model monitoring dam safety. Struct Control Health Monit 23(2):252–266

Salazar F, Toledo MA, Oñate E et al (2015) An empirical comparison of machine learning techniques for dam behaviour modelling. Struct Saf 56:9–17

Salazar F, Toledo MÁ, González JM et al (2017) Early detection of anomalies in dam performance: a methodology based on boosted regression trees. Struct Control Health Monit 24(11):e2012

Maritz J, Maritz J, Lubbe F et al (2018) A practical guide to gaussian process regression for energy measurement and verification within the Bayesian Framework. Energies 11(4):1–12

Kang F, Xu B, Li J et al (2017) Slope stability evaluation using Gaussian processes with various covariance functions. Appl Soft Comput 60:387–396

Aye SA, Heyns PS (2017) An integrated Gaussian process regression for prediction of remaining useful life of slow speed bearings based on acoustic emission. Mech Syst Signal Process 84:485–498

Roushangar K, Garekhani S, Alizadeh F (2016) Forecasting daily seepage discharge of an earth dam using wavelet-mutual information-gaussian process regression approaches. Geotech Geol Eng 34(5):1313–1326

Kong D, Chen Y, Li N (2018) Gaussian process regression for tool wear prediction. Mech Syst Signal Process 104:556–574

Lee S, Chai J (2019) An enhanced prediction model for the on-line monitoring of the sensors using the Gaussian process regression. J Mech Sci Technol 33(5):2249–2257

Yuan J, Wang K, Yu T et al (2008) Reliable multi-objective optimization of high-speed WEDM process based on Gaussian process regression. Int J Mach Tools Manuf 48(1):47–60

Hestenes MR (1980) Conjugate direction methods in optimization. Math Comput 38(157):332

Gu CS, Li B, Xu GL et al (2010) Back analysis of mechanical parameters of roller compacted concrete dam. Sci China Technol Sci 53(3):848–853

Azman K, Kocijan J (2007) Application of Gaussian processes for black-box modelling of biosystems. ISA Trans 46(4):443–457

Jiang G, Wang W (2017) Error estimation based on variance analysis of k-fold cross-validation. Pattern Recogn 69:94–106

Acknowledgements

This research has been greatly supported by the National Key Research and Development Plan (No. 2018YFC0407102). Project of the research on long term monitoring and safety evaluation of concrete dams based on BIM (DJ-ZDXM-2018-02).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lin, C., Li, T., Chen, S. et al. Gaussian process regression-based forecasting model of dam deformation. Neural Comput & Applic 31, 8503–8518 (2019). https://doi.org/10.1007/s00521-019-04375-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00521-019-04375-7