Abstract

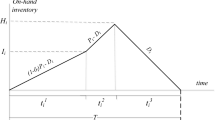

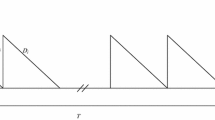

This research investigates an integrated inventory and production scheduling problem (IIPSP) in a manufacturer that deals with the perishable goods. The objective is to find an optimal schedule to minimize the sum of inventory cost and production cost. Both single-plant problem and multi-plant problem are investigated in this paper. For the single-plant problem, we prove that it is optimal to arrange the processing of raw materials in descending order of the value of the product of consumption rate and unit inventory cost. For the more complex multi-plant problem, we first prove that it is NP-hard, and then, we propose a hybrid intelligent algorithm to solve it. The experiments show that the proposed algorithm is superior to several other algorithms in both effectiveness and efficiency.

Similar content being viewed by others

References

Sana, S., Chaudhuri, K.S., Mahavidyalaya, B.: On a volume flexible production policy for a deteriorating item with time-dependent demand and shortages. Advanced Modeling and Optimization. 6(1), 57–74 (2004)

Amorim, P., Günther, H.O., Almada-Lobo, B.: Multi-objective integrated production and distribution planning of perishable products. Int. J. Prod. Econ. 138(1), 89–101 (2012)

Belo-Filho, M.A.F., Amorim, P., Almada-Lobo, B.: An adaptive large neighborhood search for the operational integrated production and distribution problem of perishable products. Int. J. Prod. Res. 53(20), 6040–6058 (2015)

Farahani, P., Grunow, M., Günther, H.O.: Integrated production and distribution planning for perishable food products. Flex. Serv. Manuf. J. 24(1), 28–51 (2012)

Devapriya, P., Ferrell, W., Geismar, N.: Integrated production and distribution scheduling with a perishable product. Eur. J. Oper. Res. 259(3), 906–916 (2017)

Chen, H.K., Hsueh, C.F., Chang, M.S.: Production scheduling and vehicle routing with time windows for perishable food products. Comput. Oper. Res. 36(7), 2311–2319 (2009)

Ekşioğlu, S. D., & Jin, M. (2006, May). Cross-facility production and transportation planning problem with perishable inventory. In International Conference on Computational Science and Its Applications (pp. 708-717). Springer, Berlin, Heidelberg

Seyedhosseini, S.M., Ghoreyshi, S.M.: An integrated model for production and distribution planning of perishable products with inventory and routing considerations. Mathematical Problems in Engineering. 2014 (2014)

Vahdani, B., Niaki, S.T.A., Aslanzade, S.: Production-inventory-routing coordination with capacity and time window constraints for perishable products: heuristic and meta-heuristic algorithms. J. Clean. Prod. 161, 598–618 (2017)

Qiu, Y., Qiao, J., Pardalos, P.M.: Optimal production, replenishment, delivery, routing and inventory management policies for products with perishable inventory. Omega. 82, 193–204 (2019)

Weiss, H.J.: Economic order quantity models with nonlinear holding costs. Eur. J. Oper. Res. 9(1), 56–60 (1982)

Ferguson, M., Jayaraman, V., Souza, G.C.: Note: an application of the EOQ model with nonlinear holding cost to inventory management of perishables. Eur. J. Oper. Res. 180(1), 485–490 (2007)

Pando, V., García-Laguna, J., San-José, L.A.: Optimal policy for profit maximising in an EOQ model under non-linear holding cost and stock-dependent demand rate. Int. J. Syst. Sci. 43(11), 2160–2171 (2012)

San-José, L.A., Sicilia, J., García-Laguna, J.: Analysis of an EOQ inventory model with partial backordering and non-linear unit holding cost. Omega. 54, 147–157 (2015)

Weng, M.X., Lu, J., Ren, H.: Unrelated parallel machine scheduling with setup consideration and a total weighted completion time objective. Int. J. Prod. Econ. 70(3), 215–226 (2001)

Atashpaz-Gargari, E., & Lucas, C. (2007, September). Imperialist competitive algorithm: an algorithm for optimization inspired by imperialistic competition. In 2007 IEEE congress on evolutionary computation (pp. 4661-4667). IEEE

Seidgar, H., Kiani, M., Abedi, M., Fazlollahtabar, H.: An efficient imperialist competitive algorithm for scheduling in the two-stage assembly flow shop problem. Int. J. Prod. Res. 52(4), 1240–1256 (2014)

Kayvanfar, V., Zandieh, M.: The economic lot scheduling problem with deteriorating items and shortage: an imperialist competitive algorithm. Int. J. Adv. Manuf. Technol. 62(5–8), 759–773 (2012)

Lian, K., Zhang, C., Gao, L., Li, X.: Integrated process planning and scheduling using an imperialist competitive algorithm. Int. J. Prod. Res. 50(15), 4326–4343 (2012)

Bahrami, H., Faez, K., & Abdechiri, M. (2010, March). Imperialist competitive algorithm using chaos theory for optimization (CICA). In 2010 12th International Conference on Computer Modelling and Simulation (pp. 98-103). IEEE

Duan, H., Xu, C., Liu, S., Shao, S.: Template matching using chaotic imperialist competitive algorithm. Pattern Recogn. Lett. 31(13), 1868–1875 (2010)

Talatahari, S., Azar, B.F., Sheikholeslami, R., Gandomi, A.H.: Imperialist competitive algorithm combined with chaos for global optimization. Commun. Nonlinear Sci. Numer. Simul. 17(3), 1312–1319 (2012)

Mladenović, N., Hansen, P.: Variable neighborhood search. Comput. Oper. Res. 24(11), 1097–1100 (1997)

Gonçalves, J.F., Resende, M.G.: Biased random-key genetic algorithms for combinatorial optimization. J. Heuristics. 17(5), 487–525 (2011)

Eberhart, R. C., & Hu, X. (1999, July). Human tremor analysis using particle swarm optimization. In proceedings of the 1999 congress on evolutionary computation-CEC99 (Cat. No. 99TH8406) (Vol. 3, pp. 1927-1930). IEEE

Zandieh, M., Khatami, A.R., Rahmati, S.H.A.: Flexible job shop scheduling under condition-based maintenance: improved version of imperialist competitive algorithm. Appl. Soft Comput. 58, 449–464 (2017). https://doi.org/10.1016/J.ASOC.2017.04.060

Ruiz, E., Soto-Mendoza, V., Barbosa, A.E.R., Reyes, R.: Solving the open vehicle routing problem with capacity and distance constraints with a biased random key genetic algorithm. Comput. Ind. Eng. 133, 207–219 (2019)

Nickabadi, A., Ebadzadeh, M.M., Safabakhsh, R.: A novel particle swarm optimization algorithm with adaptive inertia weight. Appl. Soft Comput. 11(4), 3658–3670 (2011)

Zhou, S., Liu, M., Chen, H., Li, X.: An effective discrete differential evolution algorithm for scheduling uniform parallel batch processing machines with non-identical capacities and arbitrary job sizes. Int. J. Prod. Econ. 179, 1–11 (2016). https://doi.org/10.1016/J.IJPE.2016.05.014

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Nos. 71922009, 71871080, 72071056, 71690235, 71501058, 71601060), and Innovative Research Groups of the National Natural Science Foundation of China (71521001), Anhui Province Natural Science Foundation (No. 1908085MG223, No. 2008085QG341), Base of Introducing Talents of Discipline to Universities for Optimization and Decision-making in the Manufacturing Process of Complex Product (111 projects), the Project of Key Research Institute of Humanities and Social Science in University of Anhui Province, Open Research Fund Program of Key Laboratory of Process Optimization and Intelligent Decision-making(Hefei University of Technology), Ministry of Education. Prof. Panos M. Pardalos was supported by a Humboldt Research Award (Germany).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, C., Kong, M., Pei, J. et al. Integrated inventory and production policy for manufacturing with perishable raw materials. Ann Math Artif Intell 89, 777–797 (2021). https://doi.org/10.1007/s10472-021-09739-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10472-021-09739-1