Abstract

This study develops a novel Monte Carlo simulation (MCS) approach to estimate system reliability for a stochastic production system with finite buffer storage. System reliability indicates the probability of all workstations providing sufficient capacities to satisfy a specified demand, as well as that all buffer stations are not running out of storage. First, buffer stations are modeled in a stochastic production network (SPN) model and their storage usage is analyzed based on the network-structured SPN. Second, an MCS is developed to generate the system state and to check the storage usage of buffer stations to determine whether the demand can be satisfied. After repeated simulations, the system reliability of the SPN can be estimated. Experimental results show that the proposed MCS approach is effective and efficient in estimating system reliability with reasonable quality for an SPN within a reasonable time. More importantly, system reliability will be overestimated with infinite buffer storage, and thus, it is worth studying finite buffer storage.

Similar content being viewed by others

Abbreviations

- AOA:

-

Activity-on-arc

- MCS:

-

Monte Carlo simulation

- SPN:

-

Stochastic production network

- WIP:

-

Work-in-process

- N :

-

Set of nodes (inspection stations)

- n :

-

Number of arcs (workstations)

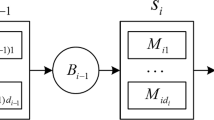

- \(a_{i}\) :

-

ith workstation

- A :

-

\(\{a_{i}|i = 1, 2, {\ldots }, n\}\): the set of workstations

- \(b_{i,i+1}\) :

-

Buffer station installed after \(a_{i}\)

- B :

-

{\(b_{i,i+1}|i\): a buffer station is installed after \(a_{i}\)}: the set of buffer stations

- r, k :

-

Defective WIP output from the rth workstation is reworked starting from the previous k workstations

- \(\varGamma ^{(\mathrm{G})}\) :

-

General processing route

- \(\varGamma ^{(\mathrm{R}|r,r-k)}\) :

-

Rework route

- \(f_i^{({\mathrm{G}})}\) :

-

Input flow for \(a_{i} \in \varGamma ^{({\mathrm{G}})}\)

- \(f_i^{({\mathrm{R}}|r,r-k)}\) :

-

Input flow for \(a_{i} \in \varGamma ^{(\mathrm{R}|r,r-k)}\)

- \(l_{i}\) :

-

Loading of \(a_{i}\) and \(l_{i}=f_i^{({\mathrm{G}})} +f_i^{({\mathrm{R}}|r,r-k)}\)

- \(M_{i}\) :

-

Maximal capacity of \(a_{i}\)

- \(x_{i}\) :

-

Capacity of each workstation \(a_{i}\)

- \(x_{i(\alpha )}\) :

-

\(\alpha \)th possible capacity of \(a_{i}\), where \(\alpha = 1, 2, {\ldots }, c_{i}\)

- \(\pi _{i(\alpha )}\) :

-

Pr(\(x_{i}=x_{i(\alpha )}\))

- \(p_{i}\) :

-

Expected success rate of \(a_{i}\)

- \({{\varvec{\Delta }}}_{c_i \times c_{i+1} }\) :

-

Matrix for different amount under all possible values of \(x_{i}\) and \(x_{i+1}\)

- \({{\varvec{\Lambda }}}_{c_i \times c_{i+1} }\) :

-

Corresponding probability distribution matrix for \({{\varvec{\Delta }}}_{c_i \times c_{i+1} }\)

- D :

-

Demand

- \(R_D^b\) :

-

Reliability for finite buffer storage for D

References

Aronson, J. E. (1989). A survey of dynamic network flows. Annals of Operations Research, 20, 1–66.

Bayliss, C., Maere, G. D., Atkin, J. A. D., & Paelinck, M. (2016). A simulation scenario based mixed integer programming approach to airline reserve crew scheduling under uncertainty. Annals of Operations Research,. doi:10.1007/s10479-016-2174-8.

Becker, C., & Scholl, A. (2006). A survey on problems and methods in generalized assembly line balancing. European Journal of Operational Research, 168, 694–715.

Chan, J. C. C., & Kroese, D. P. (2011). Rare-event probability estimation with conditional Monte Carlo. Annals of Operations Research, 189, 43–61.

Demir, L., Tunali, S., & Eliiyi, D. T. (2014). The state of the art on buffer allocation problem: A comprehensive survey. Journal of Intelligent Manufacturing, 25, 371–392.

Elsayed, E. A., & Turley, R. E. (1980). Reliability analysis of production systems with buffer storage. International Journal of Production Research, 18, 637–645.

Ford, L. R., & Fulkerson, D. R. (1962). Flows in networks. Princeton, NJ: Princeton University Press.

Ghosh, S. (1992). Routing flexibility and production scheduling in a flexible manufacturing system. European Journal of Operational Research, 60, 344–360.

Huang, H. J., & Xu, G. (1998). Aggregate scheduling and network solving of multi-stage and multi-item manufacturing systems. European Journal of Operational Research, 105, 52–65.

Huang, N. (2012). Mean station reliabilities cause throughput overestimates in production system design. Journal of Manufacturing Systems, 31, 184–194.

Kawas, B., Laumanns, M., & Pratsini, E. (2013). A robust optimization approach to enhancing reliability in production planning under non-compliance risks. OR Spectrum, 35, 835–865.

Kleintje-Ell, F., & Kiesmüller, G. P. (2015). Cost minimising order schedules for a capacitated inventory system. Annals of Operations Research, 299, 501–520.

Lin, J. S., Jane, C. C., & Yuan, J. (1995). On reliability evaluation of a capacitated-flow network in terms of minimal pathsets. Networks, 25, 131–138.

Lin, J. S. (1998). Reliability evaluation of capacitated-flow networks with budget constraints. IIE Transactions, 30, 1175–1180.

Lin, Y. K. (2007). Two-commodity reliability evaluation of a stochastic-flow network with varying capacity weight in terms of minimal paths. Computers & Operations Research, 36, 1050–1063.

Lin, Y. K., & Chang, P. C. (2012). System reliability of a manufacturing network with reworking action and different failure rates. International Journal of Production Research, 50, 6930–6944.

Lin, Y. K., & Chang, P. C. (2013). A novel reliability evaluation technique for stochastic flow manufacturing networks with multiple production lines. IEEE Transactions on Reliability, 61, 92–104.

Lin, Y. K., & Chang, P. C. (2015). Demand satisfaction and decision-making for a PCB manufacturing system with production lines in parallel. International Journal of Production Research, 53, 3193–3206.

Lin, Y. K., Fiondella, L., & Chang, P. C. (2013). Quantifying the impact of correlated failures on system reliability by a simulation approach. Reliability Engineering & System Safety, 109, 32–40.

Lin, Y. K., Kuo, P. H., & Chang, C. C. (2012). System reliability for a multistate flow network with multiple joint minimal paths under time constraint. Simulation Modelling Practice and Theory, 29, 78–92.

Lin, Y. K., Yeh, C. T., & Huang, C. F. (2014). A simple algorithm to evaluate supply-chain reliability for brittle commodity logistics under production and delivery constraints. Annals of Operations Research,. doi:10.1007/s10479-014-1741-0.

Moazeni, S., Coleman, T. F., & Li, Y. (2016). Smoothing and parametric rules for stochastic mean-CVaR optimal execution strategy. Annals of Operations Research, 237, 99–120.

Penn, M., & Raviv, T. (2007). Optimizing the quality control station configuration. Naval Research Logistics, 54, 301–314.

Ramirez-Marquez, J., & Coit, D. W. (2005). A Monte-Carlo simulation approach for approximating multi-state two-terminal reliability. Reliability Engineering & System Safety, 87, 253–264.

Stevenson, W. J. (2015). Operations management (12th ed.). New York: McGrawHill.

Xiaobo, Z., Gong, Q., & Nakashima, K. (2001). Analysis of a production system in a general configuration. Naval Research Logistics, 48, 128–143.

Yeh, C. T., & Lin, Y. K. (2016). Component allocation cost minimization for a multistate computer network subject to a reliability threshold using Tabu search. Journal of Industrial and Management Optimization, 12, 141–167.

Yeh, W. C. (2008). A simple minimal path method for estimating the weighted multi-commodity multistate unreliable networks reliability. Reliability Engineering & System Safety, 93, 125–136.

Yeh, W. C. (2011). A sequential decomposition method for estimating flow in a multi-commodity multistate network. IEEE Transactions on Reliability, 60, 612–621.

Yeh, W. C., Lin, Y. C., & Chung, Y. Y. (2010). Performance analysis of cellular automata Monte Carlo Simulation for estimating network reliability. Expert Systems with Applications, 37, 3537–3544.

Zahorik, A., Thomas, L. J., & Trigeiro, W. W. (1984). Network programming models for production scheduling in multi-stage, multi-item capacitated systems. Management Science, 30, 308–325.

Funding

This work was supported by the Ministry of Science and Technology, Taiwan, Republic of China (Grant Number MOST 103-2218-E-507-001-MY3).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, PC. Reliability estimation for a stochastic production system with finite buffer storage by a simulation approach. Ann Oper Res 277, 119–133 (2019). https://doi.org/10.1007/s10479-017-2580-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-017-2580-6