Abstract

The disassembly line plays a vital role to recover the products for remanufacturing enterprises. For this reason, designing and balancing of the disassembly line are important to utilize the economic and tactical benefits. This study explores a multi-objective disassembly line balancing problem (MODLBP) from a different point of view by considering the workers’ heterogeneity and the multi-manned stations where the group-based worker assignment strategy is implemented. Although the MODLBP has been attracting attention in the last decade, to the best of our knowledge, this is the first study investigating the addressed problem in the current form. To further analyze the problem, first, it is described by focusing on the tactical level strategies and operational level scenarios. Subsequently, a novel multi-objective optimization model is formulated with three objectives, that of minimizing overall cost, cycle time, and workload imbalance. On one hand, the improved augmented ϵ-constrained (AUGMECON2) method is used to obtain the Pareto-optimal solutions for small-sized problems. On the other hand, a set of algorithms based on the non-dominated sorting genetic algorithm-II is implemented to gain managerial insights regarding the strategies and scenarios for large-sized problems. A computational study is conducted based on the generated problems to reveal the prominent differences between strategies in terms of performance metrics. According to the computational results, high-quality solutions are achieved when the group-based assignment strategy is realized. Besides, it is revealed from scenario analysis that the training of workers leads to considerable improvements in the system performance.

Similar content being viewed by others

References

Agrawal, S., & Tiwari, M. K. (2008). A collaborative ant colony algorithm to stochastic mixed-model U-shaped disassembly line balancing and sequencing problem. International Journal of Production Research, 46(6), 1405–1429.

Akpınar, S., & Bayhan, G. M. (2011). A hybrid genetic algorithm for mixed model assembly line balancing problem with parallel workstations and zoning constraints. Engineering Applications of Artificial Intelligence, 24(3), 449–457.

Altekin, F. T., Kandiller, L., & Ozdemirel, N. E. (2008). Profit-oriented disassembly-line balancing. International Journal of Production Research, 46(10), 2675–2693.

Aslan, D. (2019). Takım çalışması esaslı demontaj hattı için optimizasyon yaklaşımı: Beyaz eşya endüstrisinde bir uygulama (Doctoral dissertation, Istanbul Technical University Graduate School of Science, Engineering, and Technology).

Avci, M. G., & Selim, H. (2018). A multi-objective simulation-based optimization approach for inventory replenishment problem with premium freights in convergent supply chains. Omega, 80, 153–165.

Avikal, S., Jain, R., & Mishra, P. (2013). A heuristic for U-shaped disassembly line balancing problems. MIT International Journal of Mechanical Engineering, 3(1), 51–56.

Avikal, S., & Mishra, P. K. (2012). A new U-shaped heuristic for disassembly line balancing problems. Pratibha International Journal of Science, Spirituality, Business and Technology, 1(1), 2277–7261.

Aydemir-Karadag, A., & Turkbey, O. (2013). Multi-objective optimization of stochastic disassembly line balancing with station paralleling. Computers & Industrial Engineering, 65(3), 413–425.

Bal, A., & Satoglu, S. I. (2018). A goal programming model for sustainable reverse logistics operations planning and an application. Journal of Cleaner Production, 201, 1081–1091.

Bentaha, M. L., Battaïa, O., & Dolgui, A. (2014a). Disassembly line balancing and sequencing under uncertainty. Procedia CIRP, 15, 239–244.

Bentaha, M. L., Battaïa, O., & Dolgui, A. (2014b). Lagrangian relaxation for stochastic disassembly line balancing problem. Procedia CIRP, 17, 56–60.

Bentaha, M. L., Battaïa, O., & Dolgui, A. (2014c). A sample average approximation method for disassembly line balancing problem under uncertainty. Computers & Operations Research, 51, 111–122.

Bentaha, M. L., Battaïa, O., & Dolgui, A. (2015). An exact solution approach for disassembly line balancing problem under uncertainty of the task processing times. International Journal of Production Research, 53(6), 1807–1818.

Bentaha, M. L., Dolgui, A., Battaïa, O., Riggs, R. J., & Hu, J. (2018). Profit-oriented partial disassembly line design: dealing with hazardous parts and task processing times uncertainty. International Journal of Production Research, 56(24), 7220–7242.

Berrichi, A., Yalaoui, F., Amodeo, L., & Mezghiche, M. (2010). Bi-objective ant colony optimization approach to optimize production and maintenance scheduling. Computers & Operations Research, 37(9), 1584–1596.

Bukchin, J., & Masin, M. (2004). Multi-objective design of team oriented assembly systems. European Journal of Operational Research, 156(2), 326–352.

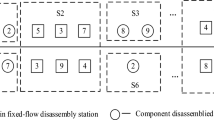

Cevikcan, E., Aslan, D., & Yeni, F. B. (2020). Disassembly line design with multi-manned workstations: a novel heuristic optimisation approach. International Journal of Production Research, 58(3), 649–670.

Chica, M., Bautista, J., Cordón, Ó., & Damas, S. (2016). A multiobjective model and evolutionary algorithms for robust time and space assembly line balancing under uncertain demand. Omega, 58, 55–68.

Çil, Z. A., & Kizilay, D. (2020). Constraint programming model for multi-manned assembly line balancing problem. Computers & Operations Research, 124, 105069.

Deniz, N., & Ozcelik, F. (2019). An extended review on disassembly line balancing with bibliometric & social network and future study realization analysis. Journal of Cleaner Production.

Dimitriadis, S. G. (2006). Assembly line balancing and group working: A heuristic procedure for workers’ groups operating on the same product and workstation. Computers & Operations Research, 33(9), 2757–2774.

Ding, L. P., Feng, Y. X., Tan, J. R., & Gao, Y. C. (2010). A new multi-objective ant colony algorithm for solving the disassembly line balancing problem. The International Journal of Advanced Manufacturing Technology, 48(5–8), 761–771.

Edis, E. B., Ilgin, M. A., & Edis, R. S. (2019). Disassembly line balancing with sequencing decisions: A mixed integer linear programming model and extensions. Journal of Cleaner Production, 238, 117826.

Fang, Y., Liu, Q., Li, M., Laili, Y., & Pham, D. T. (2019a). Evolutionary many-objective optimization for mixed-model disassembly line balancing with multi-robotic workstations. European Journal of Operational Research, 276(1), 160–174.

Fang, Y., Ming, H., Li, M., Liu, Q., & Pham, D. T. (2019b). Multi-objective evolutionary simulated annealing optimisation for mixed-model multi-robotic disassembly line balancing with interval processing time. International Journal of Production Research, 1-17.

Florios, K., & Mavrotas, G. (2014). Generation of the exact pareto set in multi-objective traveling salesman and set covering problems. Applied Mathematics and Computation, 237, 1–19.

Gümüşkaya, V. (2013). Profit-oriented disassembly line balancing with stochastic task times in hybrid lines (Master’s thesis, MIDDLE EAST TECHNICAL UNIVERSITY).

Güngör, A., & Gupta, S. M. (2002). Disassembly line in product recovery. International Journal of Production Research, 40(11), 2569–2589.

Hamacher, H. W., Pedersen, C. R., & Ruzika, S. (2007). Finding representative systems for discrete bicriterion optimization problems. Operations Research Letters, 35(3), 336–344.

He, J., Chu, F., Zheng, F., Liu, M., & Chu, C. (2019). A multi-objective distribution-free model and method for stochastic disassembly line balancing problem. International Journal of Production Research, 1–17.

Hezer, S., & Kara, Y. (2015). A network-based shortest route model for parallel disassembly line balancing problem. International Journal of Production Research, 53(6), 1849–1865.

Ilgin, M. A. (2019). A DEMATEL-based disassembly line balancing heuristic. Journal of Manufacturing Science and Engineering, 141(2), 021002.

Ishibuchi, H., Yoshida, T., & Murata, T. (2003). Balance between genetic search and local search in memetic algorithms for multiobjective permutation flowshop scheduling. IEEE Transactions on Evolutionary Computation, 7(2), 204–223.

Kalayci, C. B., & Gupta, S. M. (2013). Simulated annealing algorithm for solving sequence-dependent disassembly line balancing problem. IFAC Proceedings Volumes, 46(9), 93–98.

Kalayci, C. B., & Gupta, S. M. (2014). A tabu search algorithm for balancing a sequence-dependent disassembly line. Production Planning & Control, 25(2), 149–160.

Kalayci, C. B., Hancilar, A., Gungor, A., & Gupta, S. M. (2015). Multi-objective fuzzy disassembly line balancing using a hybrid discrete artificial bee colony algorithm. Journal of Manufacturing Systems, 37, 672–682.

Kalayci, C. B., Polat, O., & Gupta, S. M. (2016). A hybrid genetic algorithm for sequence-dependent disassembly line balancing problem. Annals of Operations Research, 242(2), 321–354.

Kazancoglu, Y., & Ozkan-Ozen, Y. D. (2019). Sustainable disassembly line balancing model based on triple bottom line. International Journal of Production Research, 1–21.

Kazancoglu, Y., & Ozturkoglu, Y. (2018). Integrated framework of disassembly line balancing with Green and business objectives using a mixed MCDM. Journal of Cleaner Production, 191, 179–191.

Kellegöz, T., & Toklu, B. (2015). A priority rule-based constructive heuristic and an improvement method for balancing assembly lines with parallel multi-manned workstations. International Journal of Production Research, 53(3), 736–756.

Koc, A., Sabuncuoglu, I., & Erel, E. (2009). Two exact formulations for disassembly line balancing problems with task precedence diagram construction using an AND/OR graph. IIE Transactions, 41(10), 866–881.

Kucukkoc, I., Li, Z., & Li, Y. (2019). Type-E disassembly line balancing problem with multi-manned workstations. Optimization and Engineering, 1–20.

Lambert, A. J. D. (2007). A heuristic for assembly and disassembly line balancing. IFAC Proceedings Volumes, 40(2), 69–74.

Li, J., Chen, X., Zhu, Z., Yang, C., & Chu, C. (2019a). A branch, bound, and remember algorithm for the simple disassembly line balancing problem. Computers & Operations Research, 105, 47–57.

Li, Z., Çil, Z. A., Mete, S., & Kucukkoc, I. (2019b). A fast branch, bound and remember algorithm for disassembly line balancing problem. International Journal of Production Research, 1–15.

Liu, H., Lei, M., Deng, H., Leong, G. K., & Huang, T. (2016). A dual channel, quality-based price competition model for the WEEE recycling market with government subsidy. Omega, 59, 290–302.

Liu, Q., Li, Y., Fang, Y., Laili, Y., Lou, P., & Pham, D. T. (2019a). Many-objective best-order-sort genetic algorithm for mixed-model multi-robotic disassembly line balancing. Procedia CIRP, 83, 14–21.

Liu, M., Liu, X., Chu, F., Zheng, F., & Chu, C. (2019b). Robust disassembly line balancing with ambiguous task processing times. International Journal of Production Research, 1–30.

Liu, J., Zhou, Z., Pham, D. T., Xu, W., Ji, C., & Liu, Q. (2020). Collaborative optimization of robotic disassembly sequence planning and robotic disassembly line balancing problem using improved discrete Bees algorithm in remanufacturing✰. Robotics and Computer-Integrated Manufacturing, 61, 101829.

Liu, J., Zhou, Z., Pham, D. T., Xu, W., Yan, J., Liu, A., et al. (2018). An improved multi-objective discrete bees algorithm for robotic disassembly line balancing problem in remanufacturing. The International Journal of Advanced Manufacturing Technology, 97(9–12), 3937–3962.

Lopes, T. C., Pastre, G. V., Michels, A. S., & Magatão, L. (2020). Flexible multi-manned assembly line balancing problem: Model, heuristic procedure, and lower bounds for line length minimization. Omega, 95, 102063.

Mavrotas, G., & Florios, K. (2013). An improved version of the augmented ε-constraint method (AUGMECON2) for finding the exact pareto set in multi-objective integer programming problems. Applied Mathematics and Computation, 219(18), 9652–9669.

McGovern, S. M., & Gupta, S. M. (2007). A balancing method and genetic algorithm for disassembly line balancing. European Journal of Operational Research, 179(3), 692–708.

Mete, S., Çil, Z. A., Özceylan, E., & Ağpak, K. (2016). Resource constrained disassembly line balancing problem. IFAC-PapersOnLine, 49(12), 921–925.

Michels, A. S., Lopes, T. C., Sikora, C. G. S., & Magatão, L. (2019). A Benders’ decomposition algorithm with combinatorial cuts for the multi-manned assembly line balancing problem. European Journal of Operational Research, 278(3), 796–808.

Ming, H., Liu, Q., & Pham, D. T. (2019). Multi-Robotic Disassembly Line Balancing with Uncertain Processing Time. Procedia CIRP, 83, 71–76.

Özceylan, E., Kalayci, C. B., Güngör, A., & Gupta, S. M. (2019). Disassembly line balancing problem: a review of the state of the art and future directions. International Journal of Production Research, 57(15–16), 4805–4827.

Özceylan, E., Paksoy, T., & Bektaş, T. (2014). Modeling and optimizing the integrated problem of closed-loop supply chain network design and disassembly line balancing. Transportation research part E: logistics and transportation review, 61, 142–164.

Paksoy, T., Güngör, A., Özceylan, E., & Hancilar, A. (2013). Mixed model disassembly line balancing problem with fuzzy goals. International Journal of Production Research, 51(20), 6082–6096.

Ren, Y., Zhang, C., Zhao, F., Tian, G., Lin, W., Meng, L., et al. (2018). Disassembly line balancing problem using interdependent weights-based multi-criteria decision making and 2-Optimal algorithm. Journal of Cleaner Production, 174, 1475–1486.

Riggs, R. J., Battaïa, O., & Hu, S. J. (2015). Disassembly line balancing under high variety of end of life states using a joint precedence graph approach. Journal of Manufacturing Systems, 37, 638–648.

Roshani, A., & Giglio, D. (2017). Simulated annealing algorithms for the multi-manned assembly line balancing problem: minimising cycle time. International Journal of Production Research, 55(10), 2731–2751.

Şahin, M., & Kellegöz, T. (2019). A new mixed-integer linear programming formulation and particle swarm optimization based hybrid heuristic for the problem of resource investment and balancing of the assembly line with multi-manned workstations. Computers & Industrial Engineering, 133, 107–120.

Shaaban, S., Hudson, S., Kalayci, C. B., & Gupta, S. M. (2013). Ant colony optimization for sequence‐dependent disassembly line balancing problem. Journal of Manufacturing Technology Management.

Teunter, R. H. (2006). Determining optimal disassembly and recovery strategies. Omega, 34(6), 533–537.

Tuncel, E., Zeid, A., & Kamarthi, S. (2014). Solving large scale disassembly line balancing problem with uncertainty using reinforcement learning. Journal of Intelligent Manufacturing, 25(4), 647–659.

Wang, S., Guo, X., & Liu, J. (2019a). An efficient hybrid artificial bee colony algorithm for disassembly line balancing problem with sequence-dependent part removal times. Engineering Optimization, 1–18.

Wang, K., Li, X., & Gao, L. (2019b). A multi-objective discrete flower pollination algorithm for stochastic two-sided partial disassembly line balancing problem. Computers & Industrial Engineering, 130, 634–649.

Wang, S., & Liu, M. (2015). Multi-objective optimization of parallel machine scheduling integrated with multi-resources preventive maintenance planning. Journal of Manufacturing Systems, 37, 182–192.

Wu, X., & Che, A. (2019). Energy-efficient no-wait permutation flow shop scheduling by adaptive multi-objective variable neighborhood search. Omega, 102117.

Yılmaz, Ö. F. (2019). Operational strategies for seru production system: A bi-objective optimisation model and solution methods. International Journal of Production Research, 1–25.

Yılmaz, Ö. F. (2020). MODALBP Problem data and results, GitHub-omerfarukktu repository. https://github.com/omerfarukktu/MODALBP-Problem-data-and-results.

Yılmaz, Ö. F., & Durmuşoğlu, M. B. (2018). Evolutionary algorithms for multi-objective scheduling in a hybrid manufacturing system. In Handbook of research on applied optimization methodologies in manufacturing systems (pp. 162–187). IGI Global.

Zhang, Z., Tang, Q., & Chica, M. (2020). Multi-manned assembly line balancing with time and space constraints: A MILP model and memetic ant colony system. Computers & Industrial Engineering, 106862.

Zhang, Z., Wang, K., Zhu, L., & Wang, Y. (2017). A Pareto improved artificial fish swarm algorithm for solving a multi-objective fuzzy disassembly line balancing problem. Expert Systems with Applications, 86, 165–176.

Zhang, L., Zhao, X., Ke, Q., Dong, W., & Zhong, Y. (2019). Disassembly line balancing optimization method for high efficiency and low carbon emission. International Journal of Precision Engineering and Manufacturing-Green Technology, 1–15.

Zheng, F., He, J., Chu, F., & Liu, M. (2018). A new distribution-free model for disassembly line balancing problem with stochastic task processing times. International Journal of Production Research, 56(24), 7341–7353.

Zhu, L., Zhang, Z., & Wang, Y. (2018). A Pareto firefly algorithm for multi-objective disassembly line balancing problems with hazard evaluation. International Journal of Production Research, 56(24), 7354–7374.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yılmaz, Ö.F., Yazıcı, B. Tactical level strategies for multi-objective disassembly line balancing problem with multi-manned stations: an optimization model and solution approaches. Ann Oper Res 319, 1793–1843 (2022). https://doi.org/10.1007/s10479-020-03902-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-020-03902-3