Abstract

This paper considers the problem of fast autonomous mobile robot navigation between obstacles while attempting to maximize velocity subject to safe braking constraints. The paper introduces position-velocity configuration space. Within this space, keeping a uniform braking distance from the obstacles can be modeled as forbidden regions called vc-obstacles. Using Morse Theory, the paper characterizes the critical position-velocity points where two vc-obstacles meet and locally disconnect the free position-velocity space. These points correspond to critical events where the robot’s velocity becomes too large to support safe passage between neighboring obstacles. The velocity dependent critical points induce a cellular decomposition of the free position-velocity space into cells. Each cell is associated with a particular range of velocities that can be safely followed by the robot. The vc-method searches the cells’ adjacency graph for a maximum velocity path. The method outputs a pseudo time optimal path which maintains safe braking distance from the obstacles throughout the robot motion. Simulations and experiments demonstrate the method and highlight the usefulness of taking the path’s velocity into account during the path planning process.

Similar content being viewed by others

Notes

One must use the generalized normal of \(\mathsf{dst}(q,B_i)\) when \(q\) has multiple nearest points on \(\mathsf{bdy}(B_i)\).

References

GUARDIUM-UGV (2012). G-NIUS unmanned ground systems. Retrieved January, from http://g-nius.co.il

GUSS, a ground unmanned support surrogate. The Naval Surface Warfare Center and TORC Robotics. Retrieved January, 2012, from http://www.torcrobotics.com/ground-unmanned-support-surrogate

Aurenhammer, F., & Klein, R. (2000). Voronoi diagrams, chap 5. In J. Sack & G. Urrutia (Eds.), Handbook of computational geometry (pp. 201–290). Amsterdam: Elsevier Science.

Brock, O., & Khatib, O. (1999). High-speed navigation using the global dynamic window approach. Proceedings of the IEEE International Conference on Robotics and Automation, pp. 341–346.

Buehler, M., Iagnemma, K., & Singh, S. (2010). The DARPA urban challenge: Autonomous vehicles in city traffic. Victorville, CA: Springer Tracts in Advanced Robotics.

Burgard, W., Cremers, A. B., Fox, D., Hahnel, D., Lakemeyer, G., Schulz, D., et al. (1999). Experiences with an interactive museum tour-guide robot. Artificial Intelligence, 114(1–2), 3–55.

Clarke, F. H. (1990). Optimization and nonsmooth analysis. Philadelphia, PA: SIAM Publication.

DARPA. Urban challenge rules. Oct. 2007. http://archive.darpa.mil/grandchallenge/docs/Urban_Challenge_Rules

Donald, B., Xavier, P., Canny, J., & Reif, J. (1993). Kinodynamic motion planning. Journal of the ACM, 40(5), 1048–1066.

Fiorini, P., & Shiller, Z. (1998). Motion planning in dynamic environments using velocity obstacles. The International Journal of Robotics Research, 17(7), 760–772.

Fox, D., Burgard, W., & Thrun, S. (1997). The dynamic window approach to collision avoidance. IEEE Robotics Automation Magazine, 4(1), 23–33.

Fraichard, T. (2007). A short paper about motion safety. In IEEE International Conference on Robotics and Automation, pp. 1140–1145.

Fujimura, K., & Samet, H. (1989). Time-minimal paths among moving obstacles. In IEEE International Conference on Robotics and Automation, pp. 1110–1115.

Goresky, M., & MacPherson, R. (1980). Stratified Morse theory. New York: Springer Verlag.

Hsu, D., Kindel, R., Latombe, J.-C., & Rock, S. (2002). Randomized kinodynamic motion planning with moving obstacles. The International Journal of Robotics Research, 21(3), 233–255.

Iagnemma, K., Shimoda, S., & Shiller, Z. (2008). Near-optimal navigation of high speed mobile robots on uneven terrain. In IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), pp. 4098–4103.

Kant, K., & Zucker, S. W. (1986). Toward efficient trajectory planning: The path-velocity decomposition. The International Journal of Robotics Research, 5(3), 72–89.

Lavalle, S. M. (1998). Rapidly-exploring random trees: A new tool for path planning. Technical report: Deptartment of Computer Science, Iowa State University.

LaValle, S. M., & Kuffner, J. J. (2000). Rapidly-exploring random trees: progress and prospects. In Workshop on the Algorithmic Foundations of Robotics.

LaValle, S. M., & Kuffner, J. J. (2001). Randomized kinodynamic planning. The International Journal of Robotics Research, 20(5), 378–400.

LaValle, S. M., & Kuffner, J. J. (2001). Algorithmic and computational robotics: New directions. Algorithmic and computational robotics: New directions (pp. 293–308). MA: Wellesley.

Parthasarathi, R., & Fraichard, T. (2007). An inevitable collision state-checker for a car-like vehicle. In IEEE International Conference on Robotics and Automation, pp. 3068–3073.

Petti, S., Fraichard, T., & Rocquencourt, I. (2005). Safe motion planning in dynamic environments. In IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), pp. 3726–3731.

Shamos, M.I. (1978). Computational geometry. Ph.D. thesis, Yale University, Section 6.3.

Shiller, Z., & Gwo, Y. R. (1991). Dynamic motion planning of autonomous vehicles. IEEE Transactions on Robotics and Automation, 7(2), 241–249.

Smith, R. H. (2008). Analyzing friction in the design of rubber products and their paired surfaces. Boca Raton, FL: CRC Press.

Snape, J., van den Berg, J., & Guy, S. J. (2011). The hybrid reciprocal velocity obstacle. IEEE Transactions on Robotics, 27(4), 696– 706.

Author information

Authors and Affiliations

Corresponding author

Appendix. The turning radius constraint

Appendix. The turning radius constraint

This appendix develops an expression for the robot’s minimal turning radius, \(r_{min}(\nu )\), as a function of the robot’s parameters. We shall assume the common case of a four-wheeled robot. However, the expression for \(r_{min}(\nu )\) can be easily adapted to other mobile robots. The three main constraints affecting a mobile robot turning radius are as follows. First, the turning radius must respect the robot’s maximal steering angles. Second, the centrifugal force affecting the robot must not incur radial sliding of the robot wheels. Third, the lateral moment affecting the robot must be sufficiently low as to prevent tip-over during turning maneuvers. The three constraints are next discussed.

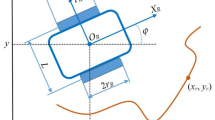

We will use the following notation. The average steering angle of the robot’s front wheels is denoted \(\alpha \) (Fig. 18a). This angle can vary in the range \([-\alpha _{max},\alpha _{max}]\). The robot’s wheels are mounted at the vertices of a rectangular frame having length \(L\) and width \(W\) (Fig. 18a). The robot’s center of mass is located at a height \(H\) above ground (Fig. 18b). The robot’s turning radius, denoted \(r\), is the current radius of curvature of the curve traced by the robot’s center point. The robot’s inner turning radius, denoted \(r_{in}\), is the current radius of curvature of the curve followed by the robot’s innermost wheel (Fig. 18a).

The kinematic turning radius constraint: Based on simple trigonometry, the average steering angle \(\alpha \) is related to \(L\), \(W\), and \(r_{in}\) by the expression:

The center point turning radius is given by

Replacing \(W/2 + r_{in}\) with \(L / \tan \alpha \) gives the turning radius:

Since \(r\) is monotonically decreasing in \(\left|\alpha \right|\), the minimal feasible turning radius, denoted \(r_{kin}\), is attained at \(\alpha = \pm \alpha _{max}\). Thus \(r \ge r_{kin}\), where

The sliding constraint: Sliding occurs when the centrifugal force acting on the robot exceeds the radial friction force acting between the wheels and the ground. The net centrifugal force, denoted \(f_r\), is given by

where \(m\) is the robot’s mass, \(\nu \) is the robot’s linear velocity magnitude, and \(r\) is the robot’s turning radius. The radial friction force acting between the wheels and the ground, denoted \(f_s\), is given by

where \(\mu \) is the friction coefficient between the wheels and the ground, and \(f_N = mg\) is the gravitational force magnitude acting downward on the robot. Sliding is prevented as long as \(f_r \le f_s\). Substituting for \(f_r\) and \(f_s\), the minimal turning radius that prevents sliding, denoted \(r_{slide}\), is given by

where \(\nu \) is the robot’s linear velocity magnitude.

The tipping-over constraint: Denote by \(\tau _{tip}\) the net moment affecting the robot about a horizontal axis passing through its outer wheels contacts with the ground. When \(\tau _{tip}\) is positive, the robot will tip-over and loose ground contact at its inner wheels (Fig. 18b). The lateral moment generated on the robot by the centrifugal force, denoted \(\tau _r\), is given by

where \(H\) is the robot’s center of mass height above ground. The stabilizing moment generated on the robot by the gravitational force is given by \(\tau _g = -mgW/2\). Tipping over is prevented when \(\tau _{tip} \!=\! \tau _r + \tau _g\) is negative semi-definite,

Tipping-over is prevented when \(r \ge r_{tip}\), where \(r_{tip}\) is given by

The robot’s minimal turning radius, denoted \(r_{min}\), must satisfy all three turning radius constraints. Based on formulas 12, 13, and 14, the minimal turning radius is specified as follows.

Lemma 9.1

The minimal turning radius of a four-wheel mobile robot moving with linear speed \(\nu \) is given by

where \(r_{kin} \!=\! L \sqrt{1/4 + 1/\tan ^2(\alpha _{max})}\) is the minimal kinematically feasible turning radius, \(r_{slide}(\nu ) \!=\! \nu ^2 / \mu g\) is the minimal sliding turning radius, and \(r_{tip}(\nu ) \!=\! (2H/g W) \nu ^{2}\) is the minimal tip-over turning radius.

Rights and permissions

About this article

Cite this article

Manor, G., Rimon, E. VC-method: high-speed navigation of a uniformly braking mobile robot using position-velocity configuration space. Auton Robot 34, 295–309 (2013). https://doi.org/10.1007/s10514-013-9322-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10514-013-9322-7