Abstract

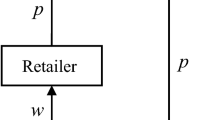

An online marketing platform should be designed to fairly take the benefits of buyers and suppliers into consideration based on their risk preferences and business strategies. In this paper, the dual-channel supply chain models are developed to implement the risk-averse strategy for buyers and risk-neutral strategy for suppliers, respectively. The buyers under the consideration are the manufacturers who acquire raw materials, parts, or components to make their final products. The major factors in the developed models include the risk preferences of buyers and suppliers, random price fluctuations of goods, and varying demands of final products. To reflect the purchasing practice of a manufacturer, (1) a supply chain is considered to have two supply channels, i.e., contract-based purchase with a lead-time before the goods are used and a direct purchase from online spot markets when the goods are used; (2) the time factor on decision making is specially taken into account, and the procurements are divided into the contract stage of purchase and online stage of purchase. Gaming analysis is conducted to develop the supply chain models for manufactures and suppliers to implement their purchasing or pricing strategies. The simulation is conducted and the result has shown that two-stage purchases in a dual-channel supply chain have improved the performances of suppliers and manufacturers in terms of the profits they can make, their supply–demand relations, and their adjustability to uncertainties in globalized and segmented markets. The proposed model has its significance for manufacturers to better control the price risk of goods and the demand risk of final products; on the other hand, suppliers can benefit from adjusting dynamic sales using online spot markets.

Similar content being viewed by others

References

Bi ZM (2011) Revisit system architecture for sustainable manufacturing. J Sustain 3(9):1323–1340

Bi ZM, Lang SYT, Shen WM (2008) Reconfigurable manufacturing systems: the state of the art. Int J Prod Res 46(4):967–992

Black JT, Kohser RA (2012) DeGarmo’s materials and processes in manufacturing. Wiley, 11th edition, ISBN : 978-0-470-92467-9

Cai G (2010) Channel selection and coordination in dual-channel supply chains. J Retail 86(1):22–36

Cai G, Zhang ZG, Zhang M (2009) Game theoretical perspectives on dual-channel supply chain competition with price discounts and pricing schemes. Int J Prod Econ 117(1):80–96

Cao W, Xu L, Liang L, Chaudhry S (2012) The impact of team task and job engagement on the transfer of tacit knowledge in e-business virtual teams. Inf Technol Manage 13(4):333–340

Chang Z, Jiang F (2004) Coordination mechanism between electronic markets and contract market in supply chain. J Huazhong Univ Sci Technol 32:111–113

Chen X, Hao G, Li L (2014) Channel coordination with a loss-verse retailer and option contracts. Int J Prod Econ 150:52–57

Cheng S, Zhang H, Lu J (2004) Supply chain modeling and simulation of dual-channel market of manufacturing enterprise. Comput Integr Manuf Syst 10(5):519–522 (in Chinese)

Chiang WK, Chhajed D, Hess JD (2003) Direct marketing, indirect profits: a strategic analysis of dual-channel supply chain design. Manage Sci 49(1):1–20

Chiang WK, Monahan GE (2005) Managing inventories in a two-echelon dual-channel supply chain. Eur J Oper Res 162(2):325–341

Eeckhoudt L, Gollier C, Schlesinger H (1995) The risk-averse (and prudent) newsboy. Manage Sci 41(5):786–794

Fisher MA, Raman A (1996) Reducing the cost of demand uncertainty through accurate response to early sales. Oper Res 44(1):87–99

Golovachkina N, Bradley J (2003) Supplier-manufacturer relationships under forced compliance contracts. Manuf Serv Oper Manage 5(1):67–69

Grey W, Olavson T, Shi D (2005) The role of e-marketplaces in relationship-based supply chains: a survey. IBM Syst J 44(1):109–123

Guo J, Xu L, Gong Z, Che C, Chaudhry S (2012) Semantic inference on heterogeneous e-marketplace activities. IEEE Trans Syst Man Cybern Part A Syst Hum 42(2):316–330

Guo J, Xu L, Xiao G, Gong Z (2012) Improving multilingual semantic interoperation in cross-organizational enterprise systems through concept disambiguation. IEEE Trans Ind Inf 8(3):647–658

Hua G, Wang S, Cheng TCE (2010) Price and lead time decisions in dual-channel supply chains. Eur J Oper Res 205(1):113–126

Lam C, Ip W (2012) An improved spanning tree approach for the reliability analysis of supply chain collaborative network. Enterp Inf Syst 6(4):405–418

Li L (2011) Assessing the relational benefits of logistics services perceived by manufacturers in supply chain. Int J Prod Econ 132:58–67

Li L (2012) Effects of enterprise technology on supply chain collaboration: analysis of China-linked supply chain. Enterp Inf Syst 6(1):55–77

Li L (2013) Technology designed to combat fakes in the global supply chain. Bus Horiz 56(2):167–177

Li L (2013) The path to made-in-China: how it was done and future prospects. Int J Prod Econ 146(1):4–13

Matook S, Lasch R, Tamaschke R (2009) Supplier development with benchmarking as part of a comprehensive supplier risk management framework. Int J Oper Prod Manage 29(3):241–267

Paulraj D, Swamynathan S, Madhaiyan M (2012) Process model-based atomic service discovery and composition of composite semantic web services using web ontology language for services (OWL-S). Enterp Inf Syst 6(4):445–471

Seifert RW, Thonemann UW, Hausman WH (2004) Optimal procurement strategies for online spot markets. Eur J Oper Res 152(3):781–799

Sepehri M (2012) A grid-based collaborative supply chain with multi-product multi-period production-distribution. Enterp Inf Syst 6(1):115–137

Shan S, Mao Z, Wang L, Zhou R, Liu Z (2013) Streaming media advertising: an empirical study. Syst Res Behav Sci 30(3):398–411

Shen H, Xu J, Pang Z (2004) Decision analysis for order- specific component procurement with loss-averse utility. J Manage Sci 7(6):37–45 (in Chinese)

Tan W, Xu W, Yang F, Xu L, Jiang C (2013) A framework for service enterprise workflow simulation with multi-agents cooperation. Enterp Inf Syst 7(4):523–542

Tang C, Tomlin B (2008) The power of flexibility for mitigating supply chain risks. Int J Prod Econ 116(1):12–27

Viriyasitavat W, Xu L, Martin A (2012) SWSpec: the requirements specification language in service workflow environment. IEEE Trans Ind Inf 8(3):631–638

Wang C, Webster S (2007) Channel coordination for a supply chain with a risk-neutral manufacturer and a loss-averse retailer. Decis Sci 38(3):361–389

Wang S, Li L, Wang K, Jones J (2012) e-business systems integration: a systems perspectives. Inf Technol Manage 13(4):233–249

Wang S, Zheng S, Xu L, Li D, Meng H (2008) A literature review of electronic marketplace research: themes, theories and an integrative framework. Inf Syst Front 10(5):555–571

Wu DJ, Kleindorfer P (2005) Competitive options, supply contracting and electronic markets. Manage Sci 51(3):452–466

Xing Y, Li L, Bi Z, Wilamowska-Korsak M, Zhang L (2013) Operations research (OR) in service industries: a comprehensive review. Syst Res Behav Sci 30(3):300–353

Xu L (2007) Editorial: inaugural issue. Enterp Inf Syst 1(1):1–2

Xu L (2011) Enterprise systems: state-of-the-art and future trends. IEEE Trans Ind Inf 7(4):630–640

Xu L (2011) Information architecture for supply chain quality management. Int J Prod Res 49(1):183–198

Xu L, Viriyasitavat W, Ruchikachorn P, Martin A (2012) Using propositional logic for requirements verification of service workflow. IEEE Trans Ind Inf 8(3):639–646

Xu S, Xu L, Basl J (2012) Introduction: advances in e-business engineering. Inf Technol Manage 13(4):201–204

Yan R, Pei Z (2009) Retail services and firm profit in a dual-channel market. J Retail Consumer Serv 16(4):306–314

Yao D, Liu J (2005) Competitive pricing of mixed retail and e-tail distribution channels. Omega 33(3):235–247

Yue X, Liu J (2006) Demand forecast sharing in a dual-channel supply chain. Eur J Oper Res 174(1):646–667

Zhang S, Li Y, Wang C (2002) Pricing model of bilateral optional electricity forward contracts. Control Decis 17(6):890–893

Zhao Q, Xiong Z, Lin Y, Bu X (2004) Game analysis of two-stage supply chain for perishable goods under e-marketplace. Chin J Manage Sci 3:91–96

Zhou H, Shou Y, Zhai X, Li L, Wood C, Wu X (2014) Supply chain practice and information quality: a supply chain strategy study. Int J Prod Econ 147:624–633

Zsidisin G (2001) Measuring supply risk: an example from Europe. Best Pract Purch Supply Chain Manage 4(3):1–6

Zsidisin G (2003) A grounded definition of supply risk. J Purch Supply Manage 9(5/6):217–224

Zsidisin G, Ellram L, Carter J, Cavinato J (2004) An analysis of supply risk assessment techniques. Int J Phys Distrib Logist Manage 34(5):397–413

Acknowledgments

Funding for this research is supported by the National Science Foundation of China (Grant Nos. 71271013, 70971004, 70971005, 71301152 and 71301011), key project of National Natural Science Foundation of China (No. 91224007),the National Social Science Foundation of China (Grant No. 11AZD096), the National Key Technology R&D Program of the Ministry of Science and Technology (Grants Nos. 2013BAK04B02, 2006BAK04A23), Quality Inspection Project (Grant No. 201010268), CSC Project (Grants No. 2011307460), Science and technology project of Beijing (Grant No. Z121100000312018), China Postdoctoral Science Foundation under Grants Nos. 2012M520008 and 2013T60091.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Y., Wang, L., Wang, Y. et al. Modeling and optimization of two-stage procurement in dual-channel supply chain. Inf Technol Manag 15, 109–118 (2014). https://doi.org/10.1007/s10799-014-0176-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10799-014-0176-2