Abstract

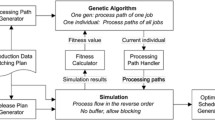

In this paper, we propose a neuro-genetic decision support system coupled with simulation to design a job shop manufacturing system by achieving predetermined values of targeted performance measures such as flow time, number of tardy jobs, total tardiness and machine utilization at each work center. When a manufacturing system is designed, the management has to make decisions on the availability of resources or capacity, in our setting, the number of identical machines in each work station and the dispatching rule to be utilized in the shop floor to achieve performance values desired. Four different priority rules are used as Earliest due date (EDD), Shortest Processing Time (SPT), Critical ratio (CR) and First Come First Serve (FCFS). In reaching the final decision, design alternatives obtained from the proposed system are evaluated in terms of performance measures. An illustrative example is provided to explain the procedure.

Similar content being viewed by others

References

R.G. Askin C.R. Standridge (1993) Modelling and Analysis of Manufacturing Systems Willey New York

R.C. Caskey (2001) ArticleTitleA manufacturing problem solving environment combining evaluation, search, and generalisation methods Computers in Industry. 44 175–187 Occurrence Handle10.1016/S0166-3615(00)00072-5

T. Cakar A. Turker G. Cagil (1996) The use of neural networks in flexible manufacturing system design Proceedings of 7th International Machine Design. and Production Conference METU Ankara Turkey 55–64

M.A.B. Candido S.K. Khatore R.M. Barcia (1998) ArticleTitleA genetic algorithm based procedure for more realistic job shop scheduling problems International Journal of Production Research 36 IssueID12 3437–3457 Occurrence Handle10.1080/002075498192148

I.H. Cedimoglu (1993) Neural Network in Shop Floor Scheduling Ph.D. Thesis, School of Industrial and Manufacturing Science Cranfield University UK.

G. Chryssolouris M. Lee J. Pierce M. Domroese (1990) ArticleTitleUse of neural networks for the design of manufacturing systems Manufacturing Review. 3 187–194

C.H. Dagli S. Sittisathanchai (1995) ArticleTitleGenetic neuro-scheduler: a new approach for job shop Scheduling International Journal of Production Economics. 41 135–145 Occurrence Handle10.1016/0925-5273(95)00072-0

T. Holter X. Yao L.S. Rabelo A. Jones Y. Yih (1995) ArticleTitleIntegration of neural networks and genetic algorithms for an intelligent manufacturing controller Computers and Industrial Engineering. 29 211–215 Occurrence Handle10.1016/0360-8352(95)00073-A

S.Y. Kim Y.H. Lee D. Agniorti (1995) ArticleTitleA hybrid approach for sequencing jobs using heuristic rules and neural networks Production Planning and Control. 6 445–454

H.C. Lee C.H. Dagli (1997) ArticleTitleA Parallel Genetic-Neuro Scheduler for Job-Shop Scheduling Problems International Journal of Production Economics. 51 115–122 Occurrence Handle10.1016/S0925-5273(97)00073-X

C.-Y. Lee S. Piramithu Y.-K. Tsai (1997) ArticleTitleJob shop scheduling with a genetic algorithm and machine learning International Journal of Production Research. 35 IssueID4 1171–1191 Occurrence Handle10.1080/002075497195605

R.E. Lenski C. Ofria R.T. Pennock C. Adami (2003) ArticleTitleThe evolutionary origin of complex features Nature. 423 139–144 Occurrence Handle10.1038/nature01568 Occurrence Handle12736677

R. Nakano T. Yamada (1993) Conventional genetic algorithms for job shop problems. Proceedings of the Fourth International Conference on Genetic Algorithms Morgan Kaufmann New York. 477–579

P.W. Philipoom L.P. Rees (1997) ArticleTitleCost based due date assignment with the use of classical and neural network approaches Naval Research Logistics. 44 421–446 Occurrence Handle10.1002/(SICI)1520-6750(199702)44:1<21::AID-NAV2>3.0.CO;2-O

H. Pierreval (1993) ArticleTitleNeural Network to select dynamic scheduling heuristic Reve des Systemes de Decision. 2 IssueID2 173–190

Pinedo M. (2002). Scheduling: Theory, Algorithms and Systems: 2nd Edition, Prentice Hall, NJ, 1995.

Rabelo, L. C., Alptekin, S. (1989) Using hybrid neural networks/expert systems for intelligent scheduling in flexible manufacturing systems. Proceedings of the IJCNN International Joint Conference on Neural Networks: June 18–22, Washington, pp.2, 608.

Rabello, L., Jones, A., Tsai, J. (1993) Using hybrid systems for FMS scheduling. 2nd Industrial Engineering Research Conference Proceedings. 471–475.

I. Sabuncuoglu (1998) ArticleTitleScheduling with neural networks: a review of the literature and new research directions Production Planning and Control. 9 IssueID1 2–12 Occurrence Handle10.1080/095372898234460

I. Sabuncuuoglu B. Gurgun (1996) ArticleTitleA neural network model for scheduling problems European Journal of Operational Research. 93 288–299 Occurrence Handle10.1016/0377-2217(96)00041-0

S.K. Sim K.T. Yeo W.H. Lee (1994) ArticleTitleAn expert neural network system, for dynamic job-shop scheduling International Journal of Production Research. 32 1759–1773

G.J. Udo (1992) ArticleTitleNeural networks applications in manufacturing processes Computers and Industrial Engineering. 1 97–100 Occurrence Handle10.1016/0360-8352(92)90072-R

S. Vaithyanathan J.P. Ignizio (1992) ArticleTitleA stochastic neural network for resource constrained scheduling Computers and Operations Research. 19 241–254 Occurrence Handle10.1016/0305-0548(92)90046-8

R. Vujosevic (1994) ArticleTitleVisual interactive simulation and artificial intelligence in design of flexible manufacturing systems International Journal of Production Research. 8 1955–1971

H. Yu W. Liang (2001) ArticleTitleNeural network and genetic algorithm-based hybrid approach to expanded job-shop scheduling Computers and Industrial Engineering. 39 337–356 Occurrence Handle10.1016/S0360-8352(01)00010-9

H.C. Zhang S.H. Huang (1995) ArticleTitleApplications of neural networks in manufacturing: a state of the art survey International Journal of Production Research. 33 705–728

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cakar, T., Yildirim, M.B. & Barut, M. A neuro-genetic approach to design and planning of a manufacturing cell. J Intell Manuf 16, 453–462 (2005). https://doi.org/10.1007/s10845-005-1657-2

Issue Date:

DOI: https://doi.org/10.1007/s10845-005-1657-2