Abstract

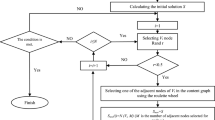

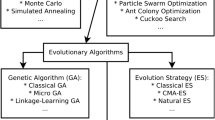

In this research, a case-based evolutionary identification model is developed for PCB defect classification problems. Image understanding is the first and foremost step in the inspection of printed circuit boards. This paper presents a two-phase method for the segmentation of printed circuit board (PCB) images. In the first phase, a set of defect images of several existing basic patterns are stored to form a concept space. In the second phase, a new pattern is evolutionally grabbed using some primitive operators generated by calculating the relative position of several similar cases in the concept space. The case-based reasoning system relies on the software agents derived from past experience within the domain database to determine what feature is required to deliver new patterns in satisfying user’s requirements. Experimental results show that the proposed approach is very effective in identifying the defect patterns.

Similar content being viewed by others

References

Akiyarnai Y., Hara N., Karasaki K. (1983). Automation inspection for printed circuit board. IEEE Transactions on Pattern Analysis and Machine Intelligence 5: 623–630

Aksoy M.S., Torkul O., Cedimoglu I.H. (2004). An industrial visual inspection system that uses inductive learning. Journal of Intelligent Manufacturing 15: 569–574

Charette B.C.P., Smith K.C., Yip A.M. (1990). Automatic visual inspection of printed circuit boards: An experiment system. International Journal of Robotic Automation 5: 1034–1044

Darwish A.M., Jain A.K. (1988) A rule based approach for visual pattern inspection pattern analysis and machine intelligence. IEEE Transactions on Pattern Analysis and Machine Intelligence 10: 56–68

Goodall A.J.E., Lo E.K. (1991). A review of inspection techniques applicable to PCB manufacturing and assembly, particularly with respect to SMT. Advanced Manufacturing Engineering 3: 18–26

Guh R.-S., Tannock J.D.T. (1999). A neural network approach to characterize pattern parameters in process control charts. Journal of Intelligent Manufacturing 10(5): 449–462

Hamada T., Nakahata K., Nornoto M., Nakagawa Y. (1990) Automated pattern inspection system for PCB photo masks using design pattern comparison method. Industrial Electronics Society, IECON’90, Annual Conference of IEEE I: 780–785

Hodges, S. E., & Richards, R. J. (1995). Fast multi-resolution image processing for PCB manufacture (pp. 1–8). Multi-resolution Modeling and Analysis in Image Processing and Computer Vision, IEE Colloquium.

Kwak C., Ventura J.A., Tofang-sazi K. (2000). A neural network approach for defect identification and classification on leather fabric. Journal of Intelligent Manufacturing 11: 485–499

Lee D.T. (1978) A computerized automatic inspection system for complex printed thick film patterns. Applied Electronic Imaging System 143: 172–177

Moganti M., Ercal F. (1998a). A sub pattern level inspection system for printed circuit board. Computer Vision and Image Understanding 70: 51–62

Moganti M., Ercal F. (1998b). Segmentation of printed circuit board images into basic patterns. Computer Vision and Image Understanding 70: 74–86

Moganti M., Ercal F., Dagli C. H., Tsunekawa S. (1996). Automatic PCB inspection algorithms: A survey. Computer Vision and Image Understanding 63: 287–313

Sanz J.L.C., Jain A.K. (1986). Machine-vision techniques for inspection of printed wiring board and thick-film circuits. Journal of Optical Society 3: 1465–1482

Scott, A. V., & Buchanan, W. J. (1999). Excluding inclusions. Manufacturing Engineer, 154–156.

Shapiro, L. G. (1980). A structural model of shape. IEEE Transactions on Pattern Analysis and Machine Intelligence, PAMI-2, 111–126.

Spence, H. F. (1991). An artificial neural networks printed circuit board diagnostic system based on infrared energy emissions. IEEE Automatic Test Conference’91 Symposium Proceedings, 41–45.

Spence, H. F. (1994). Printed circuit board diagnosis using artificial neural networks and circuit magnetic fields. IEEE Aerospace and Electronics System Magazine, 20–24.

Torres F., Jiménez L.M., Candelas F.A., Azorín J.M., Agulló R.J. (2002). Automatic inspection for phase-shift reflection defects in aluminum web production. Journal of Intelligent Manufacturing 13: 151–156

Tsunekawa H. (1992). Latest image evaluation systems aid efforts for product quality. Journal of Electronic Engineering 29: 72–22

Wu W.Y., Wang M.J., Liu C.M. (1996). Automated inspection of printed circuit boards through machine vision. Computers in Industry 28: 103–111

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, PC., Chen, LY. & Fan, CY. A case-based evolutionary model for defect classification of printed circuit board images. J Intell Manuf 19, 203–214 (2008). https://doi.org/10.1007/s10845-008-0074-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-008-0074-8