Abstract

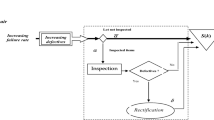

In the past three decades, studies of simultaneous maintenance and production planning have been focusing on age-dependent machine failure and inventory. This paper presents the interaction between defective products and optimal control of production rate, lead time and inventory. Our aim is to minimize the expected discounted overall cost due to maintenance activities, inventory holding and backlogs. Through Condition-Based Maintenance, we monitor in a real time the manufacturing system’s health by describing N operational states. We consider two maintenance states of a machine controlled by two decision variables: production and maintenance rates. The optimal policy is characterized by the dynamic programming solution to a piecewise deterministic optimal control problem. A numerical illustration and a sensitive analysis are developed with a set of parameters calibrated on an existing manufacturing system.

Similar content being viewed by others

References

Adzakpa K.P., Adjallah K.H., Yalaoui F. (2004) On-line maintenance job scheduling and assignment to resources in distributed systems by heuristic-based optimization. Journal of Intelligent Manufacturing 15: 131–140

Aghezzaf E. H., Najid N. M. (2008) Integrated production planning and preventive maintenance in deteriorating production systems. Information Sciences 178(17): 3382–3392

Ajodhya N. D., Damodar A. (2004) Age replacement of components during IFR delay time. IEEE Transactions on Reliability 53(3): 306–312

Akella R., Kumar P. R. (1986) Optimal control of production rate in a failure prone manufacturing system. IEEE Transactions on Automatic control AC-31(2): 116–126

Bloch H. P., Geiter F. K. (1994) Machinery failure analysis and troubleshooting. Gulf Publishing, Houston, TX

Boukas E. K., Haurie A. (1990) Manufacturing flow control and preventive maintenance: A stochastic approach. IEEE Transactions on Automatic control 33(9): 1024–1031

Davis M. (1993) Markov models and optimization. Chapman and Hall, London

Gershwin S. B. (2004) Manufacturing systems engineering. Prentice Hall, Englewood Cliffs

Gershwin, S. B., & Irvin, S. (2007). Discrete-event models for the analysis of quality/quantity interactions in production systems. ASME International Mechanical Engineering Congress. Cambridge (USA), February 07-11-2007.

Gershwin S.B., Kim J. (2008) Analysis of long flow lines with quality and operational failures. IIE Transactions 40: 284–296

Gershwin S.B., Kim J. (2005) Quality/quantity modeling and analysis of production lines subject to uncertainty phase I, final report. Massachussetts Institute of Technology Cambridge, Massachussets

Kenne J. P., Boukas E. K., Gharbi A. (2003) Control of production and corrective maintenance rates in a multiple-machine, multiple-product manufacturing system. Mathematical and computer modelling 38: 351–365

Kenne J. P., Gharbi A. (1999) Experimental design in production and maintenance control problem of a single machine, single product manufacturing system. International Journal of Production Research 37: 621–637

Kenne J.-P., Gharbi A., Beit M. (2007) Age-dependent production planning and maintenance strategies in unreliable manufacturing systems with lost sale. European Journal of Operational Research 178: 408–420

Kenne J. P., Nkengoue L. J. (2008) Simultaneous control of production, preventive and corrective maintenance rates of a failure-prone manufacturing system. Applied Numerical Mathematics 58: 180–194

Kenne J. P., Boukas E. K (2003) Hierarchical control of production and maintenance rates in manufacturing systems. Journal of Quality in Maintenance Engineering 9: 66–82

Kim J., Gershwin S.B. (2005) Integrated quality and quantity modeling of a production line. OR Spectrum 27: 287–315

Kimemia J. G., Gershwin S. B. (1983) An algorithm for computer control of production in flexible manufacturing system. IIE Transactions 15(4): 353–362

Kushner H. G. (1977) Probability methods for approximation in stochastic control and for elliptic equations. New York Academic, New York

Olsder, G. J., & Suri, R. (1980). Time optimal of parts-routing in a manufacturing system with failure prone machines. In Proceedings of the 19th IEEE Conference on decision and control, pp. 722–727. Alburquerque, Piscataway (NJ), Dec 10, 1980.

Panagiotidou S., Tagaras G. (2007) Optimal preventive maintenance for equipment with two quality states and general failure time distributions. European Journal of Operational Research 180(1): 329–353

Rishel R. (1975) Control of systems with jump Markov disturbances. IEEE Transactions on automatic Control 20: 241–244

Sortrakul N., Nachtmann H. L., Cassady C. R. (2005) Genetic algorithms for integrated preventive maintenance planning and production scheduling for a single machine. Computers in Industry 56(2): 161–168

Yang Z., Djurdjanovic D., Ni J. (2008) Maintenance scheduling in manufacturing systems based on predicted machine degradation. Journal of Intelligent Manufacturing 19: 87–98

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Njike, A.N., Pellerin, R. & Kenne, J.P. Simultaneous control of maintenance and production rates of a manufacturing system with defective products. J Intell Manuf 23, 323–332 (2012). https://doi.org/10.1007/s10845-009-0354-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-009-0354-y