Abstract

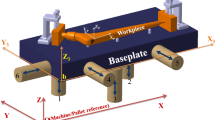

Dynamic interactions in the tool–workpiece and workpiece–fixture systems significantly impinge on the quality of finished workpieces. The presented simulation system integrates the effects of workpiece fixture dynamics with the other factors contributing to the machining process dynamics. It provides more accurate prediction of the process output which helps in the design of the optimum fixture configuration prior to the production stage. Modelling of the frictional contact behaviour between the fixture element and the workpiece helps to improve the prediction accuracy of the simulation system which accelerates the convergence to the optimum fixture configuration design and consequently improves the machined part dimensional accuracy and geometric integrity. The developed simulation is capable of modelling complicated part geometries by interfacing with commercial ANSYS.V10® packages. This research work minimizes the deformation of workpiece using integrated optimization tool of Genetic algorithm (GA) and ANSYS Parametric Design Language (APDL) of finite element analysis. The same layouts given by the above optimization tool are used in the experimental setup and it is found that the improved geometric tolerance of squarness and flatness of the given workpiece. The chip removal effect and frictional contact between the workpiece and the fixture elements are taken into account based on element death technique and nonlinear finite-element analysis. A Case study of an open slot milling process illustrates the application of the proposed improved geometric tolerance approach.

Similar content being viewed by others

References

Amaral N., Rencis J. J., Rong Y. (Kevin) (2005) Development of a finite element analysis tool for fixture design integrity verification and optimization. International Journal of Advanced Manufacturing Technology 25: 409–419

Behzadi M. R., Arezoo B. (2002) Static and dynamic models for predicting the effects of supports on machining flatness and roughness. Journal of Engineering Manufacture 216: 735–742

Chen, W., Chen, H., Ni, L., & Xue, J. (2007a). A dual optimization model of fixture design for the thin-walled workpiece. In 10th IEEE international conference, 15–18 Oct 2007, pp. 521–524.

Chen, W., Ni, L., & Xue, J. (2007b). Deformation control through fixture layout design and clamping force optimization. International Journal of Advanced Manufacturing Technology. doi:10.1007/s00170-007-1153-2.

Cook R. D., Malkus D. S., Plesha M. E. (1989) Concept and application of finite element analysis, 3rd edn. Wiley, New York

Deb, K. (1998). Genetic algorithm in search and optimization: the technique and applications. In Proceedings of international workshop on soft computing and intelligent systems (pp. 58–87). Calcutta.

Deb K. (1999) An introduction to genetic algorithms. Sadhana Journal 24: 293–315

Faupel J. H., Fisher F. E. (1981) Engineering design—a synthesis of stress analysis and materials engineering, 2nd edn. Wiley, New York

Goldberg D. E. (2000) Genetic algorithms in search optimization and machine learning. Addison-Wesley, Reading

Hurtado J. F., Melkote S. N. (1999) Workpiece fixture static friction under dynamic loading. Wear 231: 139–152

Ishikawa Y., Aoyama T. (1996) Optimization of fixturing condition by means of the genetic algorithm. Transactions of Japanese Society of Mechanical Engineers Part C 65: 2409– 2416

Johnson, K. L. (1987). Contact mechanics. Cambridge, UK: Cambridge University Press.

Kaya N., Öztürk F. (2003) The application of chip removal and frictional contact analysis for workpiece–fixture layout verification. International Journal of Advanced Manufacturing Technology 21(6): 411–419

Krishnakumar K., Melkote S. N. (2000) Machining fixture layout optimization. International Journal of Machine Tools and Manufacture 40: 579–598

Kulankara K., Satyanarayana S., Melkote S. N. (2002) Iterative fixture layout and clamping force optimization using the genetic algorithm. Journal of manufacturing science and Engineering 124(1): 119–125

Kumar A. S., Subramaniam V., Seow K. C. (1999) Conceptual design of fixtures using genetic algorithms. International Journal of Advanced Manufacturing Technology 15: 79–84

Lai X. M., Luo L. J., Lin Z. Q. (2004) Flexible assembly fixture layout modeling and optimization based on genetic algorithm. Chinese Journal of Mechanical Engineering 1: 89–92

Li B., Melkote S. N. (1999) Improved workpiece location accuracy through fixture layout optimization. International Journal of Machine Tools and Manufacture 39: 871–883

Li B., Melkote S. N. (2001) Fixture clamping force optimization and its impact on workpiece location accuracy. International Journal of Advanced Manufacturing Technology 17(2): 104– 113

Li B., Shiu B. W. (2001) Principle and simulation of fixture configuration design for sheet metal assembly with laser welding part 2 optimal configuration design with the genetic algorithm. International Journal of Advanced Manufacturing Technology 18: 276–284

Li B., Melkote S. N., Liang S. Y. (2000) Analysis of reactions and minimum clamping force for machining fixtures with large contact areas. The International Journal of Advanced Manufacturing Technology 16: 79–84

Li H. Z., Zang W. B., Li X. P. (2001) Modelling of cutting forces in helical end milling using a predictive machining theory. International Journal of Mechanical Sciences 43: 1711–1730

Liao Y. J, Hu S. J. (2000) Flexible multibody dynamics based fixture–workpiece analysis model for fixturing stability. International Journal of Machine Tools and Manufacture 40: 343– 362

Liao Y. J. G., Hu S. J. (2000) Flexible multibody dynamics based fixture–workpiece analysis model for fixturing stability. International Journal of Machine Tools and Manufacture 40: 343– 362

Liao Y. J., Hu S. J., Stephenson D. A. (1998a) Fixture layout optimization considering workpiece–fixture contact interaction: Simulation results. Transactions of NAMRI/SME 26: 341– 346

Liao Y. J., Hu S. J., Stephenson D. A. (1998b) Fixture layout optimization considering workpiece–fixture contact interaction: Simulation results. Transactions of NAMRI/SME 26: 341–346

Liao Y. G. (2003) A genetic algorithm-based fixture locating positions and clamping schemes optimization. Proceedings of the Institute of Mechanical Engineers. Part B Journal of Engineering Manufacture 217: 1075–1083

Marcelin J. L. (2001) Genetic search applied to selecting support positions in machining of mechanical parts. International Journal of Advanced Manufacturing Technology 17: 344–347

Melkote S. N. (2001) Optimal fixture design accounting for the effect of workpiece dynamics. International Journal of Advanced Manufacturing Technology 18: 701–707

Menassa R. J., DeVries W. R. (1991) Optimization methods applied to selecting support positions in fixture design. ASME Journal of Engineering for Industry 113: 412–418

Meyer R. T., Liou F. W. (1997) Fixture analysis under dynamic machining. International Journal of Production Research 35(5): 1471–1489

Mijar A. R., Arora J. S. (2000) Review of formulations for elastostatic frictional contact problems. Structural and Multidisciplinary Optimization 20: 167–189

Nee A. Y. C., Kumar A. S., Tao Z. J. (2000) An intelligent fixture with a dynamic clamping scheme. Proceedings of the Institution of Mechanical Engineers 214/B: 183–196

Padmanaban, K. P., Prabhaharan, G. (2008). Dynamic analysis on optimal placement of fixturing elements using evolutionary techniques. International Journal of Production Research, 46(15), 4177–4214.

Rajendran I., Vijayarangan S. (2001) Optimal design of composite leaf spring using genetic algorithms. Computers and Structures 79: 1121–1129

Roy U., Liao J. (1999) Geometric reasoning for re-allocation of supporting and clamping positions in the automated fixture design system. IEEE Transactions 31: 313–322

Roy U., Liao J., Sun P., Fields M. C. (1997) Fixture design synthesis for a flexible manufacturing system. Integrated Computer-Aided Engineering 4(2): 101–113

Shabana A. (1985) Substructure synthesis method for dynamic analysis of multibody systems. Computer and Structures 20: 737–744

Siebenaler S. P., Melkote S. N. (2006) Prediction of workpiece deformation in a fixture system using the finite element method. International Journal of Machine Tools and Manufacture 46: 51–58

Tan E. Y. T., Kumar A. S., Fuh J. Y. H., Nee A. Y. C. (2004) Modeling, analysis and verification of optimal fixturing design. IEEE Transactions on Automation Science and Engineering 1(2): 121–132

Tao Z. J., Kumar A. S., Nee A. Y. C. (1999) A computational geometry approach to optimum clamping synthesis of machining fixtures. International Journal of Production Research 37(11): 3495–3517

Vallapuzha S., Meter E. C., Choudhuri S. (2002) An investigation of the effectiveness of fixture layout optimization methods. International Journal of Machine Tools and Manufacture 42(2): 251–263

Vallapuzha S., Meter E. C., Choudhuri S. et al (2002) An investigation into the use of spatial coordinates for the genetic algorithm based solution of the fixture layout optimization problem. International Journal of Machine Tools and Manufacture 42(2): 265–275

Vishnupriyan S., Majumder M. C., Ramachandran K. P. (2011) Optimal fixture parameters considering locating errors. International Journal of Production Research 49(21): 6343–6361

Wang Y. F., Wong Y. S., Fuh J. Y. H. (1999) Off-line modelling and planning of optimal clamping forces for an intelligent fixturing system. International Journal of Machine Tools and Manufacture 39: 253–271

Wu N. H., Chan K. C. (1996) A genetic algorithm-based approach to optimal fixture configuration. Computers and Industrial Engineering 31(3/4): 919–924

Xie W., Meter E. C., Trethewey M. W. (2000) An experimental evaluation of coefficients of static friction of common workpiece–fixture element pairs. International Journal of Machine Tools and Manufacture 40: 467–488

Xiuwen G., Fuh J. Y. H., Nee A. Y. C. (1996) Modeling of frictional elastic fixture–workpiece system for improving location accuracy. IEE Transactions 28: 821–827

Yeh J. H., Liou F. W. (1999) Contact condition modelling for machining fixture setup processes. International Journal of Machine Tools and Manufacture 39: 787–803

Yildiz A. R. (2008) Hybrid Taguchi-harmony search algorithm for solving engineering optimization problems. International Journal of Industrial Engineering Theory, Applications and Practice 15(3): 286–293

Yildiz A. R. (2009a) A novel particle swarm optimization approach for product design and manufacturing. International Journal of Advanced Manufacturing Technology 40(5–6): 617–628

Yildiz A. R. (2009b) Hybrid immune-simulated annealing algorithm for optimal design and manufacturing. International Journal of Materials and Product Technology 34(3): 217–226

Yildiz A. R. (2009c) A novel hybrid immune algorithm for global optimization in design and manufacturing. Robotics and Computer-Integrated Manufacturing 25(2): 261–270

Yildiz A. R. (2009d) An effective hybrid immune-hill climbing optimization approach for solving design and manufacturing optimization problems in industry. Journal of Materials Processing Technology 50(4): 224–228

Yildiz, A. R. (2012). Cuckoo search algorithm for the selection of optimal machining parameters in milling operations. International Journal of Advanced Manufacturing Technology. doi:10.1007/s00170-012-4013-7.

Yildiz, A. R., Solanki K. N. (2011). Multi-objective optimization of vehicle crashworthiness using a new particle swarm based approach. International Journal of Advanced Manufacturing Technology. doi:10.1007/s00170-011-3496-y.

Zhou X. L., Zhang W. H., Qin G. H. (2005) On optimizing fixture layout and clamping force simultaneously using genetic algorithm (in Chinese). Mechanical Science and Technology 24(3): 339–342

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, K.S., Paulraj, G. Analysis and optimization of fixture under dynamic machining condition with chip removal effect. J Intell Manuf 25, 85–98 (2014). https://doi.org/10.1007/s10845-012-0677-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-012-0677-y