Abstract

Mass management and production of customized products requires material handling systems (MHS) which are flexible and responsive enough to accommodate dynamic and real-time changes in material handling tasks. Towards this goal, we develop a novel control framework to improve the flexibility and responsiveness of material handling systems. Flexibility is achieved by using multi-commodity flow network optimization to find the most optimized job sequence in terms of minimum transfer steps. Responsiveness is achieved by the use of a matrix-based discrete event (DE) supervisory controller to dispatch equipment control commands in real-time based on real-time sensor information, according to the optimized sequence. By modeling the MHS network as multi-commodity flow network to define job routes, and using the matrix-based DE controller to implement the job routes in real-time, the users achieve a seamlessly integrated solution to control the execution of transfer jobs that covers the supervisory planning stage through the real-time actual dispatching decisions. The proposed control framework is evaluated on an industrial case study of airfreight terminal material handling and simulation results show its effectiveness.

Similar content being viewed by others

References

Ahuja, R. K., Magnanti, T. L., & Orlin, J. B. (1993). Network flows: Theory, algorithms, and applications. Englewood Cliffs: Prentice Hall.

Andriansyah, R., de Koning, W., Jordan, R., Etman, L., & Rooda, J. (2011). A process algebra based simulation model of a miniload-workstation order picking system. Computers in Industry, 62(3), 292–300.

Babiceanu, R. F., & Chen, F. F. (2005). Distributed and centralised material handling scheduling: Comparison and results of a simulation study. Robotics and Computer-Integrated Manufacturing, 23(2), 441–448.

Basile, F., Chiacchio, P., & Coppola, J. (2011). A discrete event model for the control and analysis of complex automated warehouse systems. In: Proceedings of IEEE international conference on automation science and engineering. Italy: Trieste.

Bessenouci, H., Sari, Z., & Ghomri, L. (2010). Metaheuristic based control of a flow rack automated storage retrieval system. Journal of Intelligent Manufacturing. doi:10.1007/s10845-010-0432-1.

Bogdan, S., Lewis, F., Kovacic, Z., & Mireles, J. (2006). Manufacturing systems control design: A matrix based approach. London: Springer.

Bright, G., & Walker, A. (2007). Standardised framework for flexible materials handling management based on operating system primatives. In: Proceedings of the 2007 Australasian conference on Robotics & Automation. Australia: Brisbane.

Choe, R., Cho, H., Park, T., & Ryu, K. (2011). Queue-based local scheduling and global coordination for real-time operation control in a container terminal. Journal of Intelligent Manufacturing. doi:10.1007/s10845-011-0564-y.

Confessore, G., Fabiano, M., & Liotta, G. (2011). A network flow based heuristic approach for optimising AGV movements. Journal of Intelligent Manufacturing. doi:10.1007/s10845-011-0612-7.

Cormen, T. H., Leiserson, C. E., Rivest, R. L., & Stein, C. (2001). In introduction to algorithms (2nd ed., pp. 788–789). MIT Press and McGraw-Hill.

Daoud, S., Chehade, H., Yalaoui, F., & Amodeo, L. (2012). Efficient metaheuristics for pick and place robotic systems optimization. Journal of Intelligent Manufacturing. doi:10.1007/s10845-012-0668-z.

De Koster, R., Le-Duc, T., & Roodbergen, K. (2007). Design and control of warehouse order picking: A literature review. European Journal of Operational Research, 182(2), 481–501.

Dotoli, M., & Fanti, M. (2005). A coloured Petri net model for automated storage and retrieval systems serviced by rail-guided vehicles: A control perspective. International Journal of Computer Integrated Manufacturing, 18(2–3), 122–136.

Even, S., Itai, A., & Shamir, A. (1967). On the complexity of timetable and multicommodity flow problems. SIAM Journal on Computing, 5(4), 691–703.

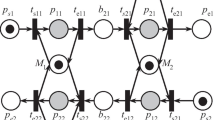

Giordano, V., Zhang, J., Naso, D., & Lewis, F. (2008). Integrated supervisory and operational control of a warehouse with a matrix-based approach. IEEE Transactions on Automation Science and Engineering, 5(1), 53–70.

Gu, J., Goetschalckx, M., & McGinnis, L. (2007). Research on warehouse operation: A comprehensive review. European Journal of Operational Research, 177, 1–21.

Gurel, A., Bogdan, S., & Lewis, F. (2000). Matrix approach to deadlock-free dispatching in multi-class finite buffer flowlines. IEEE Transactions on Automatic Control, 45(11), 2086–2090.

Harris, B., Cook, D., & Lewis, F. (2002). A matrix formulation for integrating assembly trees and manufacturing resource planning (MRP) with capacity constraints. Journal of Intelligent Manufacturing, 13(4), 239–252.

Harris, B., Lewis, F., & Cook, D. (2000). Automatically generating plans for manufacturing. Journal of Intelligent Systems, 10(3), 279–319.

Harris, B., Lewis, F., & Cook, D. (1998). Machine planning for manufacturing: Dynamic resource allocation and on-line supervisory control. Journal of Intelligent Manufacturing, 9, 413–430.

Heineman, G., Pollice, G., & Stanley, S. (2009). Algorithms in a Nutshell. California, U.S.A: O’Reilly Media.

Jung, S., & Kim, K. (2006). Load scheduling for multiple quay cranes in port container terminals. Journal of Intelligent Manufacturing, 17(4), 479–492.

Kusiak, A. (1992). Intelligent scheduling of automated machining system. In: Intelligent design and manufacturing (pp. 421–430). New York, U.S.A: Wiley.

Le-Anh, T., de Koster, R., & Yu, Y. (2010). Performance evaluation of dynamic scheduling approaches in vehicle-based internal transport systems. International Journal of Production Research, 48(24), 7219–7242.

Lin, L., Shinn, S., Gen, M., & Hwang, M. (2006). Network model and effective evolutionary approach for AGV dispatching in manufacturing system. Journal of Intelligent Manufacturing, 17(4), 465–477.

Luo, M., Zhang, J., Wong, M., Zhuang, L., Ng, K., & Aung, S. (2005). A heuristic approach to auto-recovery in the supervisory control of heterogeneous automatic equipment for material handling. In: Proceedings of 31st annual conference of IEEE industrial electronics society (IECON 2005), (pp. 2325–2330).

McAree, P., Bodin, L., & Ball, M. (2002). Models for the design and analysis of a large package sort facility. Networks, 39(2), 107–120.

Medina, L., Bilsel, R., Wysk, R., Prabhu, V., & Ravindran, A. (2009). Simulation for predictive control of a distribution center. In: M. Rossetti, R. Hill, B. Johansson, A. Dunkin, & R. Ingalls (Eds.), Proceedings of the 2009 winter simulation conference.

Mireles, J., & Lewis, F. L. (2001). Intelligent material handling: Development and implementation of a matrix-based discrete-event controller. IEEE Transactions on Industrial Electronics, 48(6), 1087–1097.

Nishi, T., Ando, M., & Konishi, M. (2006). Experimental studies on a local rescheduling procedure for dynamic routing of autonomous decentralized AGV systems. Robotics and Computer-Integrated Manufacturing, 22(2), 154–165.

Ouelhadj, D., & Petrovic, S. (2009). A survey of dynamic scheduling in manufacturing systems. Journal of Scheduling, 12(4), 417–431.

Roodbergen, K., & Vis, I. (2009). A survey of literature on automated storage and retrieval systems. European Journal of Operational Research, 194, 343–362.

Rubrico, J., Higashi, T., Tamura, H., & Ota, J. (2011). Online rescheduling of multiple picking agents for warehouse management. Robotics and Computer-Integrated Manufacturing, 27(1), 62–71.

Steward, D. (1981). The design structure system: A method for managing the design of complex systems. IEEE Transactions on Engineering Management, 28(3), 71–74.

Tacconi, D., & Lewis, F. (1997). A new matrix model for discrete event systems: Application to simulation. IEEE Control System Magazine, 17(5), 62–71.

van der Meer, J. (2000). Operational Control of Internal Transport. ERIM Ph.D. dissertation. TRAIL Res. School, Amsterdam, The Netherlands, Research in management series, also available online as TRAIL Thesis T2000/5.

Wang, C.-N., & Chen, L.-C. (2011). The heuristic preemptive dispatching method of material transportation system in 300 mm semiconductor fabrication. Journal of Intelligent Manufacturing. doi:10.1007/s10845-011-0531-7.

Wong, M., Tan, C., Zhang, J., Zhuang, L., Zhao, Y., & Luo, M. (2008). On-line reconfiguration to enhance the routing flexibility of complex automated material handling operations. Robotics and Computer-Integrated Manufacturing, 23, 294–304.

Yang, J.-W., Cheng, H.-C., Chiang, T.-C., & Fu, L.-C. (2008). Multiobjective lot scheduling and dynamic OHT routing in a 300-mm wafer fab. IEEE International Conference on Systems, Man and Cybernetics (SMC), (pp. 1608–1613). Singapore.

Acknowledgments

This work was supported by the National Science Foundation ECS-1128050, the Army Research Office W91NF-05-1-0314 and the Air Force Office of Scientific Research FA9550-09-1-0278.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Joe, Y.Y., Gan, O.P. & Lewis, F.L. Multi-commodity flow dynamic resource assignment and matrix-based job dispatching for multi-relay transfer in complex material handling systems (MHS). J Intell Manuf 25, 681–697 (2014). https://doi.org/10.1007/s10845-012-0713-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-012-0713-y