Abstract

In multi-mixed model assembly lines, customer orders with different demand of models and due dates make it critical to decide the sequencing of different models and balancing of lines. Therefore, current research, first time, investigated an order oriented simultaneous sequencing and balancing problem of multi-mixed model assembly lines with an aim to minimize the variation in material usage, minimize the maximum makespan among the multi-lines and minimize the penalty cost of the late delivery models from different orders simultaneously. Moreover, a new mix-minimum part sequencing method is developed and a multi-objective artificial bee colony (MABC) algorithm is proposed to get the solution for the considered problem. Experiments are performed on standard assembly line data taken from operations library (OR) to test the performance of the proposed MABC algorithm against a famous multi-objective algorithm (Strength Pareto Evolutionary Algorithm i.e. SPEA 2) in literature. Moreover, the proposed MABC algorithm is also tested on the data taken from a well reputed manufacturing company in China against the famous algorithm in literature (i.e. SPEA 2). End results indicate that the proposed MABC outperforms SPEA 2 algorithm for both standard data and company data problems.

Similar content being viewed by others

References

Al-e-hashem, S. M. J. M., Aryanezhad, M. B., & Jabbarzadeh, A. (2011). A new approach to solve a mixed-model assembly line with a bypass sub line sequencing problem. International Journal of Advance Manufacturing Technology, 52, 1053–1066.

Bolat, A. (2003). A mathematical model for selecting mixed-models with due dates. International Journal of Production Research, 41(5), 897–918.

Celano, G., Costa, A., & Fichera, S. (2004). A comparative analysis of sequencing heuristics for solving the Toyota Goal Chasing problem. Robot Computer integrated manufacturing journal, 20, 573–581.

Coello, C. A. C., & Cortes, N. C. (2005). Solving multi-objective optimization problems using an artificial immune system. Genetic Programming and Evolvable Machines, 6, 163–190.

Dar-El, E. M., & Nadivi, A. (1981). A mixed-model sequencing application. International Journal of Production Research, 19, 69–84.

Ding, F. Y., & Tolani, R. (2003). Production planning to support mixed-model assembly. Computers and Industrial Engineering, 45(3), 375–392.

Dong, Q. Y., Lu, J. S., & Gui, Y. K. (2012). Integrated optimization of production planning and scheduling in mixed model assembly line. In 2012 international workshop on information and electronics engineering. Procedia engineering, 29 (pp. 3340–3347).

Dörmer, J., Günther, H. O., Gujjula, R., & Friedrich, K. (2010). Master production scheduling for high-variant mixed-model assembly lines. In 2010 17th international annual EurOMA conference: managing operations in service economies. Portugal: Porto.

Dormer, J., Gunther, H. O., & Gujjula, R. (2013). Master production scheduling and sequencing at mixed-model assembly lines in the automotive industry. Flexible Services and Manufacturing Journal,. doi:10.1007/s10696-013-9173-8.

Gans, J. E. (2008). Neu-und Anpassungsplanung der Struktur von getakteten Fließproduktionssystemen für variantenreiche Serienprodukte in der Montage. Dissertation, Universität Paderborn, Paderborn.

Hindi, K. S., & Ploszajski, G. (1994). Formulation and solution of a selection and sequencing problem in car manufacture. Computers and Industrial Engineering, 26(1), 203–211.

Jiang, Z., Lin, Li, Zhi, Li, & Zhaoqian, Li. (2012). Order-oriented cooperative sequencing optimisation in multi-mix-model assembly lines. International Journal of Production Research, 50(24), 7198–7209.

Karabati, S., & Sayin, S. (2003). Assembly line balancing in a mixed-model sequencing environment with synchronous transfers. Euorpian Journal of Operations Research, 149(2), 417–429.

Karaboga, D. (2005). An idea based on honey bee swarm for numerical optimization. Technical report TR06. Turkey: Computer Engineering Department, Erciyes University.

Kim, M., Hiroyasu, T., Miki, M., & Watanabe, S. (2004). SPEA2+: Improving the performance of the strength pareto evolutionary algorithm 2. In Lecture notes in computer science, 3242, 742–751.

Kim, Y. K., Kim, Y. J., & Kim, Y. (1996). Genetic algorithms for assembly line balancing with various objectives. Computers and Industrial Engineering, 30(3), 397–409.

Kim, Y. K., Kim, J. Y., & Kim, Y. (2000). A coevolutionary algorithm for balancing and sequencing in mixed model assembly lines. Applied Intelligence, 13, 247–258.

Li, J.-Q., Pan, Q.-K., & Gao, K.-Z. (2011). Pareto-based discrete artificial bee colony algorithm for multi-objective flexible job shop scheduling problems. International Journal of Advance Manufacturing Technology, 55, 1159–1169.

Manavizadeh, N., Goodarzi, A. H., Rabbani, M., & Jolai, F. (2013). Order acceptance/rejection policies in determining the sequence in mixed-model assembly lines. Applied Mathematical Modelling, 37(4), 2531–2551.

Mansouri, S. A. (2005). A multi-objective genetic algorithm for mixed-model sequencing on JIT assembly lines. European Journal of Operational Research, 167(3), 696–716.

Miltenburg, J. (1989). Level schedules for mixed-model assembly lines in just-in-time production systems. Management Science, 35(2), 192–207.

Mosadegh, H., Zandieh, M., & Fatemi Ghomi, S. M. T. (2012). Simultaneous solving of balancing and sequencing problems with station-dependent assembly times for mixed-model assembly lines. Applied Soft Computing, 12, 1359–1370.

Pan, Q. K., Tasgetiren, M. F., Suganthan, P. N., & Chua, T. J. (2011). A discrere artificiall bee colony algorithm for the lot-streaming flowshop scheduling problem. Information Science, 181(12), 2455–2468.

Saif, U., Guan, Z., Liu, W., Zhang, C., & Wang, B. (2014). Multi-objective artificial bee colony algorithm for simultaneous sequencing and balancing of mixed model assembly line. The International Journal of Advanced Manufacturing Technology, 75(9–12), 1809–1827.

Scholl, A. (1993). Data of Assembly Line Balancing Problems. Working Paper, TH Darmstadt.

Scholl, A. (1999). Balancing and sequencing assembly lines (2nd ed.). Heidelberg: Physica.

Simaria, A. S., & Vilarinho, P. M. (2004). A genetic algorithm based approach to the mixed model assembly line balancing problem of type II. Computers and Industrial Engineering, 47, 391–407.

Tapkan, P., Ozbakir, L., & Baykasoglu, L. (2012). Modeling and solving constrained two aided assembly line balancing problem via bee algorithms. Applied Soft Computing, 12(1), 3343–3355.

Tasgetiren, M. F., Pan, Q. K., Suganthan, P. N., & Chen, A. H.-L. (2011). A discrete artificial bee colony algorithm for the total flowtime minimization in permutation flow shops. Information Sciences, 181(16), 3459–3475.

Volling, T. (2009). Auftragsbezogene Planung bei variantenreicher Serienproduktion. Dissertation, Technische Universität Braunschweig, Gabler, Wiesbaden.

Volling, T., & Spengler, T. S. (2011). Modeling and simulation of order-driven planning policies in build-to-order automobile production. International Journal of Production Economics, 131(1), 183–193.

Wang, G., Cui, H., & Xu, P. (2010). Order schedule on multi-mixed-model assembly lines in assembly-to-order environments. In 2010 international conference of information science and management engineering, Xi’an, Aug 7–8, 1 (pp. 563–566).

Wang, B., Guan, Z., Chen, Y., Shao, X., Jin, M., & Zhang, C. (2013). An assemble-to-order production planning with the integration of order scheduling and mixed-model sequencing. Frontier of Mechanical Engineering, 8(2), 137–145.

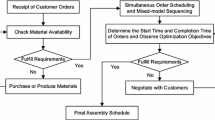

Wang, B., Guan, Z. L., Saif, U., Xianhao, Xu, & Zongdong, He. (2014). Simultaneous order scheduling and mixed-model sequencing in assemble-to order production environment: a multi-objective hybrid artificial bee colony algorithm. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-014-0988-2.

Watanabe, S., Hiroyasu, T., & Miki, M. (2002). Neighborhood cultivation genetic algorithm for multi-objective optimization problems. In 2012 4th Asia-Pacific conference on simulated evolution and learning (SEAL-2002) (pp. 198–202).

Zhang, W., Lin, L., Gen, M., & Chien, C. F. (2012). Hybrid sampling strategy-based multi-objective evolutionary algorithm. Procedia Computer Science, 12, 96–101.

Zhang, W., & Gen, M. (2011). An efficient multi-objective genetic algorithm for mixed-model assembly line balancing problem considering demand ratio-based cycle time. Journal of Intelligent Manufacturing, 22, 367–378.

Zitzler, E., Deb, K., & Thiele, L. (2000). Comparison of multi-objective evolutionary algorithms: Empirical results. Evolutionary Computation, 8(2), 173–195.

Zitzler, E., Laumanns, M., & Thiele, L. (2001). SPEA2: Improving the strength Pareto evolutionary algorithm. Zurich, Switzerland: Swiss Federal Institute Techonology.

Acknowledgements

This work has been supported by MOST (Ministry of Science & Technology of China) under the Grants Nos. 2012AA040909, 2012BAH08F04, & 2013AA040206, and by the National Natural Science Foundation of China (Grants Nos. 51035001, 50825503, & 71271156).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saif, U., Guan, Z., Zhang, L. et al. Multi-objective artificial bee colony algorithm for order oriented simultaneous sequencing and balancing of multi-mixed model assembly line. J Intell Manuf 30, 1195–1220 (2019). https://doi.org/10.1007/s10845-017-1316-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-017-1316-4