Abstract

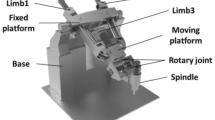

In recent years parallel kinematic machines for wood machining have come into use more frequently. Despite first promising prototypes, these machines are single solutions for specific applications. To meet the requirements of shorter product life cycles and higher product diversity, high flexibility is demanded of the machining system. This paper presents a new wood machining center obtaining both, the reduction of the primary and secondary processing times. The machine concept, based on a parallel kinematic structure, allows high operating speeds and accelerations not only for workpiece machining but also for handling. Thus, the machine can be used without any external handling devices. The kinematic structure originates from a plane closed five-bar chain with two linear drives and additional drive axes for stroke and rotation. In order to increase the useable workspace a continuous motion between different assembly modes is realized. To guarantee a high feed rate and to minimize set-up times, an optimized dust exhaustion is included.

Similar content being viewed by others

References

Schuler G (2004) Die Zukunft der Holz- und Möbelindustrie, eine Herausforderung an die Maschinenhersteller. Proceedings: 12. Braunschweiger Holztechnisches Kolloquium, Essen, Vulkan-Verlag, pp 1.1–1.7

Peisker T (2004) Flexibilisierung leistungsfähiger Fertigungsmethoden—Stückzahl 1 Fertigung in Durchlaufmaschinen. Proceedings: 12. Braunschweiger Holztechnisches Kolloquium, Essen, Vulkan-Verlag, pp 2.1–2.7

Merlet JP (2000) Parallel robots. Kluwer, Dordrecht

Lell F (2002) Kombiniertes HSC-Fräsen und Laserabtragen—Möglichkeiten und Grenzen. Proceedings: 10. Internationales Braunschweiger Feinbearbeitungskolloquium, Essen, Vulkan-Verlag, pp 19.1–19.19

Hesselbach J, Frindt M (2000) Structural classification and systematic design of machines basing on parallel structures. In: Proceedings of 31st international symposium on robotics, Montreal/Kanada, pp 65–70

Chen TI, Li C, Angeles J (2004) Managing singularities of 3-d.o.f. planar parallel manipulators using joint-coupling. In: Proceedings of 11th world congress in mechanism and machine science, Tianjin/China pp 1966–1970

Hesselbach J, Helm M, Soetebier S (2002) Connecting assembly modes for workspace enlargement. Advances in robot kinematics. Kluwer, Dordrecht, pp 347–356

Di Gregorio R (2002) Dynamic performance indices for 3-d.o.f. parallel manipulators. In: Lenarcic J, Thomas F (eds) Proceedings: ARK. Kluwer, Dordrecht, pp 11–20

Krefft M, Hesselbach J (2005) A way to the optimal design of parallel robots with high dynamic capabilities. In: Proceedings of IASTED international conference on robotics and applications, Cambridge, pp 249–254

Blecken J (2004) Optimierung der Staub- und Späneerfassung in stationären Holzbearbeitungsmaschinen. Dissertation, TU Braunschweig

Kessel MH, Hoffmeister HW, Armbrecht C (2005) Simulation-based optimization of manufacturing processes in the wood-working industry. In: Proceedings of the 17th international wood machining seminar. Rosenheim, pp 332–336

Hesselbach J, Hoffmeister HW, Armbrecht C, Kessel MH (2006) Simulation of automation concepts for an optimized production of timber-frame houses. Production Engineering Research and Development. Ausgabe XIII/1, pp 131–134

Hesselbach J, Hoffmeister HW, Loohß T (2006) Examination of a parallel kinematic concept for stationary high performance cutting in wood machining centers. In: Proceedings of 5th Chemnitz parallel kinematics seminar. Chemnitz, pp 22–23

Hoffmeister HW, Loohß T (2006) Development of a parallelkinematic concept for stationary high performance cutting in wood machining centers. In: Proceedings of forest products society 60th international convention. Newport Beach, pp 20, 50

Acknowledgment

This work has been funded by the German Research Foundation (DFG) within the Priority Program 1099 “Production Machines with Parallel Kinematics”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hesselbach, J., Hoffmeister, HW., Loohß, T. et al. Parallel kinematic concept for stationary high performance cutting in wood machining centers. Prod. Eng. Res. Devel. 1, 205–212 (2007). https://doi.org/10.1007/s11740-007-0033-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-007-0033-9