Abstract

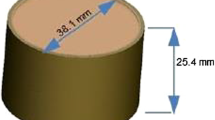

The paper concentrates on investigation results dealing with ultra high performance concrete (UHPC) dies for the use in sheet metal hydroforming. A special mixture of UHPC for these tools with its mechanical properties and its manufacturing is presented. The developed UHPC features a compressive strength of approx. 250 MPa and a Young’s modulus of approx. 50 GPa. Applying internal pressure, the UHPC die (without confinement or reinforcement) failed between 80 and 96 MPa. The forming test proved a good shape accuracy of the sheet metal parts but revealed critical tribological conditions. Drawing foil and already formed sheet metal parts were tested successfully as interlayer and led to an appropriate material flow and surface quality of the sheet metal parts.

Similar content being viewed by others

References

Finckenstein EV (1990) Sondertiefziehverfahren. In: Lange K (Hrsg.): Umformtechnik—Blechbearbeitung. Bd. 3. Springer, Heidelberg, pp 449–467

Kleiner M, Homberg W, Brosius A (1999) Processes and control of sheet metal hydroforming. In: Advanced technology of plasticity. Proceedings of the 6th international conference on technology of plasticity—ICTP, 19-24.9. Springer, Nürnberg, pp 1243–1252

Kunieda M, Nakagawa T (1984) Manufacturing of laminated deep drawing dies by laser beam cutting. Adv Technol Plasticity I

Matsuda F, Kito S, Tanaka T, Kokao K (2004) Fe-particle strengthened low-melting-point alloy composite for casting die. J Die Mold Techol 7(10):Japan

Frank C (1999) Kunststoff als Werkzeugwerkstoff für das Tiefziehen von Feinblechen. Dr-Ing Dissertation, University of Hannover

Kurth W (1956) Wirtschaftliche Kaltumformung von dünnen Blechen in kleinen Serien. Fertigungstechnik 6

Musil J (1973) Application of hydroformig for the manufacturing of complex parts for aircraft construction (Czech). Strojirenska Vyroba

Cerusev B (1983) Forming of large area sheet metal parts in non-metal dies by electric discharge in water (Russian). Kuznecnostampovocnoe Proizvodstvo

Yaofu G, Naicheng G, Daren Z, Mancai H (1992) The superplastic forming of metal sheets using a die of refractory concrete. J Mater Process Technol 30

Nakagawa T (2000) Advances in prototype and low volume sheet forming and tooling. J Mater Process Technol 98

Schwartzentruber A, Bournazel J-P, Gacel J-N (1999) Hydraulic concrete as a deep drawing tool of sheet steel. Cem Concr Res 29

Richard P, Cheyrezy M (1995) Composition of reactive powder concretes. Cem Concr Res 25:1501–1511

Schmidt M, Geisenhanslüke C (2005) Optimierung der Zusammensetzung des Feinstkorns von Ultra-Hochleistungs- und von selbstverdichtendem Beton. Beton 55(5):224–23

De Larrard F, Sedran T (1994) Optimization of ultra-high-performance concrete by the use of a packing model. Cem Concr Res 24:997–1009

Schachinger I (2000) Untersuchungen an Hochleistungs-Feinkorn-Beton. Tagungsbeiträge zum 38. Forschungskolloquium des Deutschen Ausschuss für Stahlbeton (DAfStb.), S. München, pp 55–66

Ritter R (2006) Spannungs-Dehnungs-Verhalten von ultra-hochfestem Beton in Abhängigkeit von der Umschnürungswirkung. Diplomarbeit, TU Dresden

Hampel T, Curbach C (2000) Behavior of high performance concrete under multiaxial loading. In: Proceedings of the PCI/FHWA/FIB international symposium on high performance concrete. Orlando, pp 185–196

Curbach M, Hampel T, Scheerer S, Speck K (2002) Hochleistungsbeton unter zwei- und dreiaxialer Beanspruchung. Beton-und Stahlbetonbau 97(6):275–280

Acknowledgment

This paper is based on investigations within the scope of a research project that is kindly supported by the Deutsche Forschungsgemeinschaft (DFG).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kleiner, M., Curbach, M., Tekkaya, A.E. et al. Development of ultra high performance concrete dies for sheet metal hydroforming. Prod. Eng. Res. Devel. 2, 201–208 (2008). https://doi.org/10.1007/s11740-008-0099-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-008-0099-z