Abstract

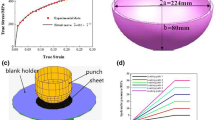

Double sheet hydroforming is a technology which allows to manufacture lightweight hollow components with complex geometries in one forming operation. One major challenge in hydroforming regards the manufacturing of inhomogeneous double sheet parts, i.e., of components, where the two halves are made up of different materials or have a different initial thickness. The failure mechanisms taking place in this case are due to the different amount of draw-in of material in the die during the preforming, which causes the occurrence of wrinkling in the flange, and to the different bursting pressure of the two blanks during the successive calibrating stage. An innovative strategy is proposed, in which a counterpressure is applied at the outer surface of one of the two sheets in order to compensate the different behaviors of the two forming partners, allowing thus to exploit their forming potential.

Similar content being viewed by others

References

Celeghini M (2004) Wirkmedienbasierte Blechumformung: Grundlagenuntersuchungen zum Einfluss von Werkstoff und Bauteilgeometrie. In: Geiger M, Feldmann K (Hrsg) Reihe Fertigungstechnik, Band 150, Bamberg, Meisenbach

Merklein M, Geiger M, Blankl A, Cojutti M, Vogt U (2006) Prozesskettenverkürzung in der Blechumformung. In: Geiger M, Singer RF (Hrsg) Tagungsband zum Industriekolloquium des SFB 396, Bamberg, Meisenbach

Marciniak Z, Duncan JL (1992) The mechanics of sheet metal forming. Edward Arnold, London

Storakers B (1966) Finite plastic deformation of a circular membrane under hydrostatic pressure. Int J Mech Sci 8:619–628. doi:10.1016/0020-7403(66)90040-3

Hein P (1999) Innenhochdruck-Umformen von Blechpaaren: Modellierung, Prozessauslegung und Prozessführung. In: Geiger M, Feldmann K (Hrsg) Reihe Fertigungstechnik, Band 96, Bamberg, Meisenbach

Acknowledgments

The authors would like to thank the German Research Foundation DFG for their financial support of the project, which is part of the DFG Collaborative Research Center 396: “Robust, shortened process sequences for sheet lightweight parts”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Geiger, M., Merklein, M. & Cojutti, M. Hydroforming of inhomogeneous sheet pairs with counterpressure. Prod. Eng. Res. Devel. 3, 17–22 (2009). https://doi.org/10.1007/s11740-008-0128-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-008-0128-y