Abstract

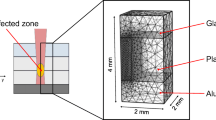

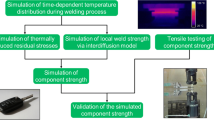

Laser transmission welding of plastics is a joining technique which permits the welding of plastic parts with low process inherent thermal and mechanical stresses. In order to compute the temperature fields during the welding process a simulation model of the process is established. Especially the optical and thermal properties of the welded materials are necessary as input parameters in order to model the process properly. While the thermal properties of polymers are well-investigated, there is little knowledge about the optical properties of plastics. The optical properties of different amorphous and semi-crystalline thermoplastics are therefore investigated in dependence on material temperature and additive concentration. Based on these data it is possible to analytically describe the absorption of laser energy in plastics. The computation of temperature fields during welding is carried out for polypropylene and the results are then compared with experimentally accomplished welding tests. The calculated results show good accordance with the experimentally determined melt pool geometries of welded specimens and prove the compatibility of the computation model with the experimental analysis.

Similar content being viewed by others

References

Bates PJ, Mah JC, Zou XP, Wang CY, Baylis B (2004) Vibration welding air intake manifolds from reinforced nylon 66, nylon 6 and polypropylene. In: Composites part A: applied science and manufacturing 35(9):1107–1116

Suresh KS, Roopa Rani M, Prakasan K, Rudramoorthy R (2007) Modeling of temperature distribution in ultrasonic welding of thermoplastics for various joint designs. J Mater Process Technol 186(3):138–146

Qiu J, Takahata H, Hunag Y, Pan Y (2008) The relationship between interfacial structure and welding strength of hot plate welding crystalline polymer. Kobunshi Ronbunshu 65:235–237. doi:10.1295/koron.65.235

Haberstroh E, Hoffmann W-M (2006) Laser welding of plastics—a technological overview. Weld Cut 5:349–354

Frick T, Hopfner M (2007) Laser welding of thermoplastics (BLZ user handbook, vol 1). Erlangen

Frick T (2007) Untersuchung der prozessbestimmenden Strahl-Stoff-Wechselwirkungen beim Laserstrahlschweißen von Kunststoffen, Dissertation, Universität Erlangen-Nürnberg

Cowie JMG, Arrighi V (2007) Polymers: chemistry and physics of modern materials. Taylor & Francis, London

Frick T (2007) Computation of temperature fields for laser transmission welding of plastics. In: Proceedings of the 26rd international congress on applications of lasers and electro-optics (ICALEO), Orlando, USA

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Geiger, M., Frick, T. & Schmidt, M. Optical properties of plastics and their role for the modelling of the laser transmission welding process. Prod. Eng. Res. Devel. 3, 49–55 (2009). https://doi.org/10.1007/s11740-008-0141-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-008-0141-1