Abstract

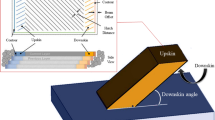

Many forged parts e.g. connection rods or box spanners feature cavities, holes or apertures, which have to be produced in an additional process step (in many cases warm piercing). The residual material, that remains at the cross sectional area of the piercing punch, so called web, has to be pierced in an additional manufacturing step. By integrating this separately performed operation into the final forging step the process chain can be shortened. However, up to date there is no information available on how the process parameters influence quality relevant factors like dimensional accuracy, surface quality, and fibre orientation in the pierced area when forming and piercing operations are combined. Therefore, a combined forging-/piercing process was designed and performed in two projects. In the first project, not discussed in this paper, forging temperature, tool and work piece material as well as the thickness of the web have been investigated. The results of these investigations showed that the variation of the inserted mass and the forging temperature have a distinct effect on the dimensional and form accuracy of the work pieces. The second project investigated different geometries of the piercing punch and the influence of a different forming sequence on tool stress and material flow. The geometry of punch shows no effect on the geometrical tolerances of the piercing while an inappropriate forming sequence leads to failure of the tool.

Similar content being viewed by others

References

Balendra R (2001) Net-shape forming: state of the art. J Mater Process Technol 115(2):172–179

Flüß A (2002) Entwicklung eines Werkzeugsystems zur Fertigung gelochter Präzisionsschmiedestücke. Dissertation Universität Hannover

Gruss D, Kache H, Rüther T (2009) Stoffflussverhalten und Werkzeugverschleiß beim gratlosen Präzisionsschmieden. In: MaschinenMarkt MM, Vogel-Buchverlag, o. Jg, H. 16, S. 22–27

Doege E, Behrens B-A (2007) Handbuch umformtechnik–grundlagen, technologien, maschinen. Springer, Berlin

Klocke F, König W (2006) Fertigungsverfahren 4–umformen. 5. aufl. Springer, Berlin

Behrens B-A et al (2004) Precision forging processes for high-duty automotive components. ICAMT, Kuala Lumpur

Meyer E, Schott A (2005) Untersuchungen zum kombinierten Umformen und Lochen. SchmiedeJournal. pp 16–18

Karpuschewski B, Falkenberg Y (1996) Verkürzung technologischer Prozessketten. Technica 13/14/96

König W, Lennartz J (1993) Fertigungsfolge Fließpressen-Zerspanen. VDI-Z, p 135

Hustedt P (2003) Modular aufgebaute Vorformwerkzeuge für das Schmieden von Langteilen. Dissertation Universität Hannover

Thalemann J (1994) Ohne Span. Mit dem Präzisionsschmieden lassen sich endkonturnahe Bauteile herstellen. Maschinenmarkt, p 100

Podgomrnik B, Hogmark S, Sandberg O, Leskovsek V (2002) Wear resistance and anti-sticking properties of duplex treated forming tool steel. Conference paper NORDTRIB 2002, 10th Nordic Symp. On Tribology, Stockholm

Herold J (2003) Einfluss der Kantengestaltung von Schneidstempeln beim Scherschneiden auf die Stempelstandzeit. II, www.utfscience.de

Hartke B, Adams B (1987) Warmlochen von Gesenkschmiedestücken. Herstellen form- und lagegenauer Durchbrüche. Industrieanzeiger, Band 109 Heft 20, 38

Acknowledgments

We would like to thank the German Research Foundation for the financial funding of the projects (BE 1691/77-3) and RE 2207/8-2.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Behrens, BA., Kerkeling, J. Pierced forgings: tool development for a combined single step process. Prod. Eng. Res. Devel. 5, 201–207 (2011). https://doi.org/10.1007/s11740-010-0285-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-010-0285-7