Abstract

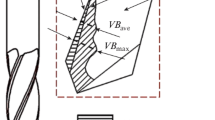

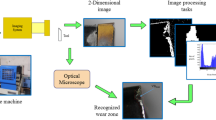

This paper suggests a novel technique for the tool wear measurement based on machine vision. Tool images are captured between cutting operations using a machine vision system. The gray value difference threshold is determined from the tool image itself and the reference line is found to locate the tool in the image. The edges of the tool wear region are extracted by column scanning. A method of continuity testing is used to find the correct edge position in each wear column. To achieve a more accurate result, the sub-pixel edge detection technology is adopted to extract the edges. Finaly, the tool wear parameters can be obtained after rebuilding the top edge of the wear region and determining the bottom edge of the wear region. The measurement results gotten by the proposed method are compared with those gotten by measuring directly with a microscope. The proposed scheme is shown to be reliable and effective for the automated tool wear measurement.

Similar content being viewed by others

References

Malekian M, Park SS, Jun MBG (2009) Tool wear monitoring of micro-milling operations. J Mater Process Technol 209:4903–4914

Huang SN, Tan KK, Wong YS et al (2007) Tool wear detection and fault diagnosis based on cutting force monitoring. Int J Mach Tools Manuf 47:444–451

Shao H, Wang HL, Zhao XM (2004) A cutting power model for tool wear monitoring in milling. Int J Mach Tools Manuf 44:1503–1509

Gómez MP, Hey AM, Ruzzante JE et al (2010) Tool wear evaluation in drilling by acoustic emission. Phys Procedia 3:819–825

Kurada S, Bradley C (1997) A review of machine vision sensors for tool condition monitoring. Comput Ind 34:55–72

Wang W, Wong YS, Hong GS (2005) Flank wear measurement by successive image analysis. Comput Ind 56:816–830

Wang WH, Hong GS, Wong YS (2006) Flank wear measurement by a threshold independent method with sub-pixel accuracy. Int J Mach Tools Manuf 46:199–207

Pfeifer T, Wiegers L (2000) Reliable tool wear monitoring by optimized image and illumination control in machine vision. Measurement 28:209–218

Su JC, Huang CK, Tarng YS et al (2006) An automated flank wear measurement of microdrills using machine vision. J Mater Process Technol 180:328–335

Castejon M, Alegre E, Barreiro J et al (2007) On-line tool wear monitoring using geometric descriptors from digital images. Int J Mach Tools Manuf 47:1847–1853

Jurkovic J, Korosec M, Kopac J (2005) New approach in tool wear measuring technique using CCD vision system. Int J Mach Tools Manuf 45:1023–1030

Kim J-H, Moon D-K, Lee D-W et al (2002) Tool wear measuring technique on the machine using CCD and exclusive jig. J Mater Process Technol 130–131:668–674

Devillez A, Lesko S, Mozer W (2004) Cutting tool crater wear measurement with white light interferometry. Wear 256:56–65

Niranjan Prasad K, Ramamoorthy B (2001) Tool wear evaluation by stereo vision and prediction by artificial neural network. J Mater Process Technol 112:43–52

Lanzetta M (2001) A new flexible high-resolution vision sensor for tool condition monitoring. J Mater Process Technol 119:73–82

Acknowledgments

The authors would like to acknowledge the financial supports from the Natural Science Foundation of China (Grant no. 50805078), Postdoctoral Science Foundation of China (Grant no. 20100471340) and basic scientific research foundation of Nanjing University of Aeronautics and Astronautics (Grant no. 56XAA11010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, J., Zhang, C., Guo, S. et al. Research on tool wear detection based on machine vision in end milling process. Prod. Eng. Res. Devel. 6, 431–437 (2012). https://doi.org/10.1007/s11740-012-0395-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-012-0395-5