Abstract

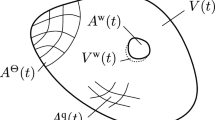

The wear-resistance of sheet metal forming tools can be increased by thermally sprayed coatings. However, without further treatment, the high roughness of the coatings leads to poor qualities of the deep drawn sheet surfaces. In order to increase the surface quality of deep drawing tools, grinding on machining centers is a suitable solution. Due to the varying engagement situations of the grinding tools on free-formed surfaces, the process forces vary as well, resulting in inaccuracies of the ground surface shape. The grinding process can be optimized by means of a simulative prediction of the occurring forces. In this paper, a geometric-kinematic simulation coupled with a finite element analysis is presented. Considering the influence of individual grains, an additional approximation to the resulting topography of the ground surface is possible. By using constructive solid geometry and dexel modeling techniques, multiple grains can be simulated with the geometric-kinematic approach simultaneously. The process forces are predicted with the finite element method based on an elasto-plastic material model. Single grain engagement experiments were conducted to validate the simulation results.

Similar content being viewed by others

References

Aurich J, Kirsch B (2012) Kinematic simulation of high-performance grinding for analysis of chip parameters of single grains. CIRP J Manuf Sci Technol 5(3):164–74. doi:10.1016/j.cirpj.2012.07.004

Bailey M, Hedges L (1995) Die Kristallmorphologie von Diamant und ABN. IDR 3:126–29

Blum H, Schröder A, Rademacher A, Ludwig H, Kleemann H, Rosin K (2013) SOFAR: scientific object oriented finite element library for application and research. http://www.mathematik.tu-dortmund.de/lsx/research/software/sofar/index.html. Accessed 11 Nov 2013

Brinksmeier E, Aurich J, Govekar E, Heinzel C, Hoffmeister HW, Peters J, Rentsch R, Stephenson D, Uhlmann E, Weinert K, Wittmann M (2006) Advances in modelling and simulation of grinding processes. Ann CIRP 55:667–96. doi:10.1016/j.cirp.2006.10.003

China jiangyou longhai Special Steel Co L (2011) Data table for: tool steel 1.3343. http://www.steelss.com/Tool-steel/din-1-3343.html. Accessed 11 Nov 2013

Deichmueller M, Denkena B, de Payrebrune KM, Kröger M, Wiedemann S, Schröder A, Carstensen C (2013) Modeling of process machine interactions in tool grinding. In: Denkena B, Hollmann F (eds) Process machine interactions, Springer, Berlin pp 143–76. doi:10.1007/978-3-642-32448-2_7

Denkena B, Kühler J, Kästner J (2012) Chip formation in grinding: an experimental study. Prod Eng Res Dev 6:107–15. doi:10.1007/s11740-011-0360-8

Foley JD, Van Dam A, Feiner SK, Hughes JF, Phillips RL (1993) Introduction to computer graphics. Addison-Wesley, Reading

Frohne J (2011) FEM-Simulation der Umformtechnik metallischer Oberflächen im Mikrokosmos. PhD thesis, University of Siegen

Geuzaine C, Remacle JF (2009) Gmsh: a three-dimensional finite element mesh generator with built-in pre- and post-processing facilities. Int J Numer Methods Eng 79(11):1309–31. doi:10.1002/nme.2579

Haslinger J (1981) Mixed formulation of elliptic variational inequalities and its approximation. Appl Math 26:462–75

Holtermann R, Schumann S, Menzel A, Biermann D (2013) Modelling, simulation and experimental investigation of chip formation in internal traverse grinding. Prod Eng Res Dev 7:251–63. doi:10.1007/s11740-013-0449-3

Johnson C (1978) On plasticity with hardening. J Math Anal Appl 62:325–36

Kienzle O, Victor H (1952) Die Bestimmung von Kräften und Leistungen an spanenden Werkzeugen und Werkzeugmaschinen. VDI-Z 94:299–305

Kikuchi N, Oden JT (1988) Contact problems in elasticity: a study of variational inequalities and finite element methods. SIAM, Philadelphia

Kleemann H (2011) Adaptive FEM für Mehrkörperkontaktprobleme. PhD thesis, Technische Universität Dortmund

Mohn T, Rausch S, Biermann D (2010) Grinding simulation by technologically enhanced and geometrically optimized multi-dexel models. In: CIRP ICME ’10–7th CIRP international conference on intelligent computation in manufacturing engineering, Italy

Murthy J, Rao D, Venkataraman B (2001) Effect of grinding on the erosion behavior of a wc-co-cr coating deposited by hvof and detonation gun spray processes. Wear 249:592–600. doi:10.1016/S0043-1648(01)00682-2

Rausch S, Biermann D (2012) Grinding of hard-material-coated forming tools on machining centers. Procedia CIRP 1:388–92. doi:10.1016/j.procir.2012.04.069

Rausch S, Odendahl S, Kersting P, Biermann D, Zabel A (2012) Simulation-based prediction of process forces for grinding free-formed surfaces on machining centers. Procedia CIRP 4:161–65. doi:10.1016/j.procir.2012.10.029

Ruttimann N, Buhl S, Wegener K (2010) Simulation of single grain cutting using sph method. J Mach Eng 10:17–29

Tekkaya AE, Kleiner M, Biermann D, Hiegemann L, Rausch S, Franzen V, Kwiatkowski L, Kersting P (2013) Friction analysis of thermally sprayed coatings finished by ball burnishing and grinding. Prod Eng Res Dev 7:601–10. doi:10.1007/s11740-013-0485-z

Tillmann W, Vogli E, Baumann I, Krebs B, Nebel J (2009) Thermally sprayed wear-protective cermet coatings for forming tools. In: 4th international conference on spray deposition and melt atomization (SDMA), Bremen

Weinert K, Stautner M (2002) An efficient discrete simulation for five-axis milling of sculptured surfaces. Prod Eng Res Dev 9(1):47–51

Wiederkehr T, Kout A, Müller H (2008) Graphical simulation and visualization of spray-coating processes in computer-aided engineering. In: Proceedings vision, modeling and visualization (VMV) 2008

Zabel A, Odendahl S, Peuker A (2009) Combining different modeling techniques to optimize the simulation of the five-axis milling process. In: Proceedings of the 5th international conference and exhibition on design and production of machines and dies/molds, Turkey

Acknowledgments

This research has been kindly funded by the German Research Foundation (DFG) in research project A5 “Simulation supported NC-shape grinding as a finishing operation of thermally coated deep drawing tools” within the Collaborative Research Center (SFB) 708” 3D-Surface Engineering of Tools for Sheet Metal Forming–Manufacturing, Modeling, Machining”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Siebrecht, T., Biermann, D., Ludwig, H. et al. Simulation of grinding processes using finite element analysis and geometric simulation of individual grains. Prod. Eng. Res. Devel. 8, 345–353 (2014). https://doi.org/10.1007/s11740-013-0524-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-013-0524-9