Abstract

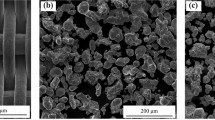

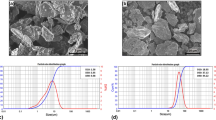

The paper deals with a new process chain consisting of powder metallurgy (PM) and a subsequent thixoforging process. This innovative production process can increase the complexity of PM components and enable a high formability of brittle materials such as metal matrix composites (MMC). Compared to conventional materials MMCs feature improved mechanical properties and thus a high potential for various applications. In this investigation cylindrical raw parts, consisting of a steel powder and different proportions of titanium carbide particles, were produced by uniaxial powder pressing and sintering. Subsequently, the samples were heated up to the thixotropic (semi-solid) temperature range and valve parts were thixoforged by a backwards rod extrusion process. Finally, the particle-reinforced steel parts were characterised by metallographic analysis and hardness measurements.

Similar content being viewed by others

References

Schatt W (2007) Pulvermetallurgie: Technologien und Werkstoffe, 2. bearbeitete und erweiterte Auflage. Springer, Berlin

Esper FJ (1996) Pulvermetallurgie. Renningen, Expert Verlag

Koether R, Rau W (2008) Fertigungstechnik für Wirtschaftsingenieure, 3. aktualisierte Auflage. Carl Hanser, Munich

Saltykova A (2010) Verschleißbeständige in situ MMC durch Sintern in flüssiger Phase. Dissertation, Ruhr-Universität Bochum

Beffort O (2002) Internationales IWF-Kolloquium 18/19 April 2002, Egerkingen, Schweiz

Bao CG, Wang EZ, Gao YM, Xing JD (2005) Effect of volume fraction of particle on wear resistance of Al2O3/steel composites at elevated temperature. J Iron Steel Res Int 12(2):60–63

Patankar SN, Tan MJ (2000) Role of reinforcement in sintering of SiC/316L stainless steel composite. Powder Metall 43(4):350–352

Parashivamurthy KI, Kumar RK, Seetharamu S, Chandrasekharaiah MN (2001) Review on TiC reinforced steel composites. J Mater Sci 36(18):4519–4530

Baxter D, Tarrant A, Valle R (2004) Development of particalute reinforced stainless steel composites. PM, powder metallurgy world congress, 2004, Euro PM, European Congress and Exhibition on Powder Metallurgy, pp 307–313

Fritz A, Schulze G (2008) Fertigungstechnik, 8. neu bearbeitet auflage. Springer, Berlin

Doege E, Behrens B-A (2010) Handbuch Umformtechnik: Grundlagen, Technologien, 2. bearb. Auflage. Springer, Berlin

Haller B (2006) Einfluss der Prozessparameter beim Thixoschmieden des Stahls C60. Dissertation, Leibniz Universität Hannover

Fischer D (2008) Entwicklung eines vollautomatisierten Produktionsprozesses für die Herstellung von Stahlbauteilen durch Thixoschmieden. Dissertation, Leibniz Universität Hannover

Abdelfattah S (2002) Thixoschmieden im geschlossenen Gesenk zur Herstellung komplexer Stahlbauteile. Dissertation, Leibniz Universität Hannover

Lecomte-Beckers J, Rassili A, Carton M, Robelet M, Koeune R (2007) Study of the liquid fraction and thermophysical properties of semi-solid steels and application to the simulation of inductive heating for thixoforming. In: Advanced Methods in Material Forming, Springer, Berlin, pp 321–347

Hemminger WF, Cammenga HK (1989) Methoden der thermischen Analyse. Springer, Berlin

Schwarz S (2011) Dispersionverstärkte Sinterstähle hergestellt über Field Assisted Sintering, Schriftenreihe des Instituts für Keramik im Maschinenbau, IKM 58. Dissertation, KIT, Karlsruhe

Acknowledgments

The presented results are based on the framework of the research project “Production of complex geometries of particle reinforced steel materials by powder compaction followed by thixoforging”. The authors would like to thank the German Research Foundation (DFG) for the financial support and Quebec Metal Powders Limited (Rio Tinto) for cooperating and providing the steel powder.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Behrens, BA., Frischkorn, C. Thixoforging of particle-reinforced steel materials. Prod. Eng. Res. Devel. 8, 335–343 (2014). https://doi.org/10.1007/s11740-014-0533-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-014-0533-3